A Guide to Selecting the Perfect Guide Pillar Material for Your Application

Guide pillars play a crucial role in the precision and efficiency of various industrial applications, particularly in the field of mold and die manufacturing. These essential components provide guidance and support, ensuring smooth and accurate movement within machines and molds. However, to harness their full potential, it’s essential to choose the right guide pillar material tailored to your specific application. In this comprehensive guide, we will explore the factors to consider when selecting guide pillar materials and delve into the various options available.

Table of contents

The Significance of Guide Pillars

Guide pillars, also known as guide posts, are cylindrical components designed to guide and support moving parts within machinery, molds, and dies. They ensure proper alignment and minimize friction, contributing to the overall efficiency and longevity of the equipment. Choosing the correct guide pillar material is critical to achieving optimal performance and minimizing wear and tear.

Factors to Consider When Selecting Guide Pillar Materials

Load-Bearing Capacity: One of the primary considerations when choosing guide pillar materials is their load-bearing capacity. Different applications require guide pillars capable of withstanding varying levels of force and pressure. For heavy-duty applications, materials with high compressive strength, such as hardened steel, are often preferred. In contrast, lighter loads may be adequately supported by materials like aluminum or bronze.

Wear Resistance

The guide pillar’s ability to resist wear and friction is paramount. High wear resistance ensures a longer service life and reduces maintenance costs. Materials like hardened steel, bronze, or self-lubricating alloys, such as graphite-impregnated materials, are excellent choices for applications where wear is a concern.

Corrosion Resistance

Depending on the working environment, guide pillars may be exposed to moisture, chemicals, or other corrosive agents. In such cases, selecting materials with corrosion-resistant properties, like stainless steel or corrosion-resistant coatings, is essential to prevent premature deterioration.

Temperature Resistance

Some applications involve extreme temperatures, either high or low. Guide pillar materials should be selected based on their ability to maintain dimensional stability and strength within these temperature ranges. Heat-treated steel alloys and ceramics are examples of materials suitable for high-temperature environments.

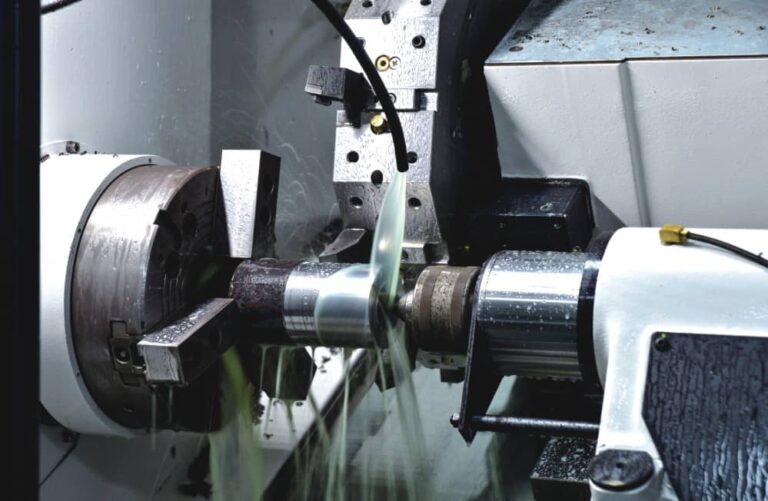

Machinability

Ease of machining is a crucial factor to consider, especially for custom or complex guide pillar designs. Materials that are readily machinable, like aluminum or bronze, can simplify the manufacturing process and reduce production time.

Common Guide Pillar Materials

Several materials are commonly used for guide pillars, each offering unique advantages:

Hardened Steel: Known for its exceptional strength and wear resistance, hardened steel guide pillars are ideal for heavy-load applications where durability is crucial.

Bronze

Bronze guide pillars offer excellent self-lubricating properties, making them suitable for applications requiring minimal maintenance and reduced friction.

Aluminum

Lightweight and corrosion-resistant, aluminum guide pillars are preferred for applications where weight reduction is a priority.

Stainless Steel

Stainless steel guide pillars excel in environments where corrosion resistance and hygiene are paramount, such as food processing or medical equipment.

Graphite-Impregnated Materials

These self-lubricating guide pillars reduce friction and wear, making them suitable for applications where smooth movement is essential.

Selecting the right guide pillar material is a critical decision that significantly impacts the performance and longevity of industrial machinery and molds. By carefully considering factors such as load-bearing capacity, wear resistance, corrosion resistance, temperature resistance, and machinability, you can make an informed choice that aligns with your specific application requirements. Whether you opt for hardened steel, bronze, aluminum, stainless steel, or graphite-impregnated materials, the proper selection will lead to improved efficiency, reduced downtime, and enhanced product quality.

For expert guidance and a wide selection of high-quality guide pillar materials tailored to your needs, feel free to contact Gunri Mold Components. Our team of professionals is dedicated to providing you with the best solutions for your industrial applications. Your success is our priority.