Billet vs Cast Crankshafts: What’s Better for Your Engine?

Keywords: billet crankshaft, cast crankshaft, forged crankshaft, crankshaft material comparison, billet vs cast crankshaft

Whether you’re building a high-performance race car, restoring a classic engine, or upgrading a diesel generator, choosing the right crankshaft is critical. Among the most debated questions is:

“Should I use a billet crankshaft or a cast crankshaft?”

Each type offers distinct advantages depending on your engine application, power output, budget, and usage environment. In this article, we’ll break down the differences between billet and cast crankshafts, compare them side by side, and help you decide which one is better for your specific needs.

What Is a Billet Crankshaft?

A billet crankshaft is machined from a single solid piece of high-grade steel (typically 4340 or 42CrMo4). It’s precisely CNC-machined to final shape with tight tolerances.

Key Features:

- Machined from a solid billet of steel

- Superior grain structure alignment

- Common in racing engines and high-stress applications

- More expensive, but stronger and more customizable

What Is a Cast Crankshaft?

A cast crankshaft is made by pouring molten iron or steel into a mold. Once cooled, the raw casting is machined into its final shape.

Key Features:

- Economical to produce

- Suitable for low to medium horsepower engines

- Less resistant to extreme stress or RPM

- Common in OEM applications for mass production

Comparison Table: Billet vs Cast Crankshaft

| Feature | Billet Crankshaft | Cast Crankshaft |

|---|---|---|

| Material Source | Solid billet (4340, 42CrMo) | Cast iron / cast steel |

| Strength | ★★★★★ (Highest) | ★★☆☆☆ (Moderate) |

| Fatigue Resistance | Excellent | Fair |

| Customizability | High (e.g., stroke, counterweights) | Low |

| Cost | $$$$ (High) | $ (Affordable) |

| Typical Applications | Racing, diesel performance, aviation | Mass-market engines, stock rebuilds |

| Availability | Made-to-order | Widely available |

| Machining Tolerance | Very tight (±0.01 mm) | Moderate |

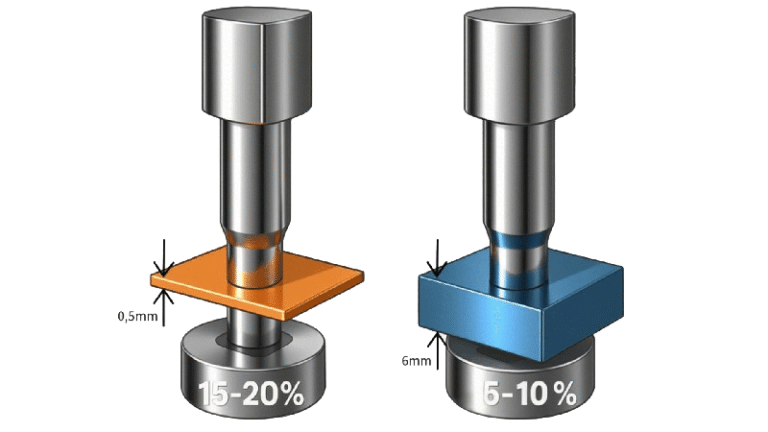

Grain Flow and Strength: Why Billet Wins

One of the biggest structural advantages of a billet crankshaft lies in its grain structure. Because it’s machined from a rolled or forged steel billet, the material’s internal grain aligns naturally along the shaft, especially in stress-critical areas like rod journals and fillets. This enhances:

- Fatigue life

- Torsional resistance

- Load-bearing strength under high RPM

In contrast, cast crankshafts have randomized grain structure and more microscopic voids, making them more susceptible to cracking under stress.

When to Choose a Billet Crankshaft

You should consider billet if:

- Your engine exceeds 600–700 horsepower

- You frequently run at high RPMs (>7,000 RPM)

- You’re building a track-only or drag race engine

- You need custom stroke/rod journal sizing

- Your project involves aviation, heavy diesel, or marine engines

When Cast Crankshafts Are Enough

Cast crankshafts are ideal if:

- Your engine is under ~500 HP

- You’re doing a factory-style rebuild

- Your budget is limited

- The engine won’t see high-RPM stress or nitrous/boost

Cast crankshafts are cost-effective and reliable for most street and OEM-level builds.

What About Forged Crankshafts?

There’s a middle ground: forged crankshafts.

- Stronger than cast

- Cheaper than billet

- Good for up to ~700 HP applications

- Manufactured by pressing heated steel into dies

- Common in performance engines and diesel trucks

💡 If billet is too expensive and cast is too weak, a 4340 forged crankshaft might be your perfect choice.

Billet vs Cast – Real-World Example

Let’s compare performance in two scenarios:

| Use Case | Recommended Crankshaft |

|---|---|

| 450 HP Street Engine | Cast or Forged |

| 900 HP Drag Racing Engine | Billet (preferred) |

| Marine Diesel Generator | Billet (for durability) |

| Stock Toyota Camry | Cast (OEM) |

| Off-Road Diesel Truck | Forged or Billet |

Summary: Which One’s Better?

| If you want… | Go for… |

|---|---|

| Maximum strength and durability | ✅ Billet |

| Affordable rebuild for stock power | ✅ Cast |

| Good balance of price and performance | ✅ Forged (middle) |

Verdict:

- For high-power, high-risk, or custom builds → Billet

- For budget or factory spec builds → Cast

- For moderate performance on a budget → Forged

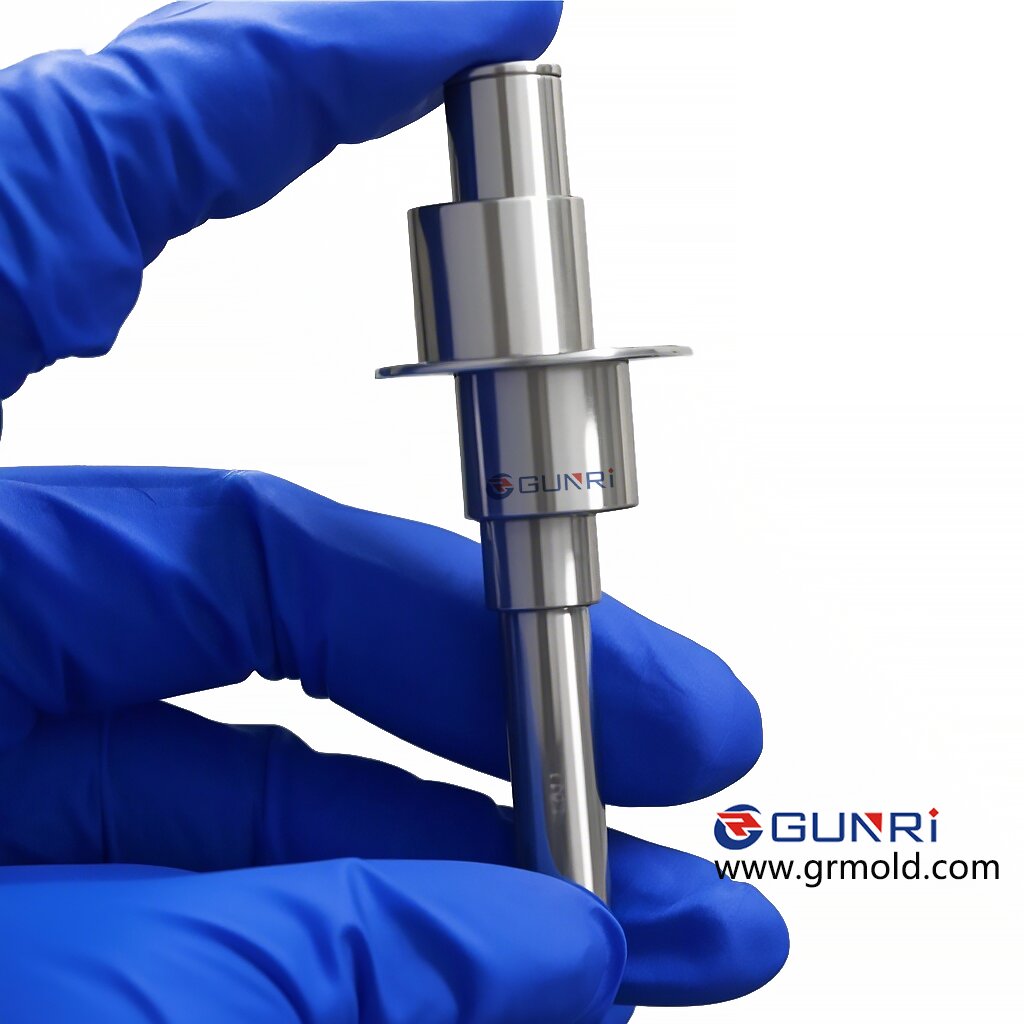

Need High-Precision Crankshafts?

At gunri, we manufacture and export:

- Billet crankshafts for racing, diesel, marine, and aviation

- Forged crankshafts (4340/42CrMo) for up to 1000 HP

- OEM replacement cast crankshafts with tight QC

📩 Contact us for a quote, drawings, or samples.

FAQ

Q: Are billet crankshafts worth the cost?

A: If you’re running a high-performance engine or need custom specs, yes. Their strength and fatigue life are unmatched.

Q: Can a cast crankshaft handle 500 HP?

A: It depends on material and usage, but many cast units are rated for ~400–500 HP with conservative tuning.

Q: How long does it take to machine a billet crankshaft?

A: Around 10–15 days depending on complexity and volume.