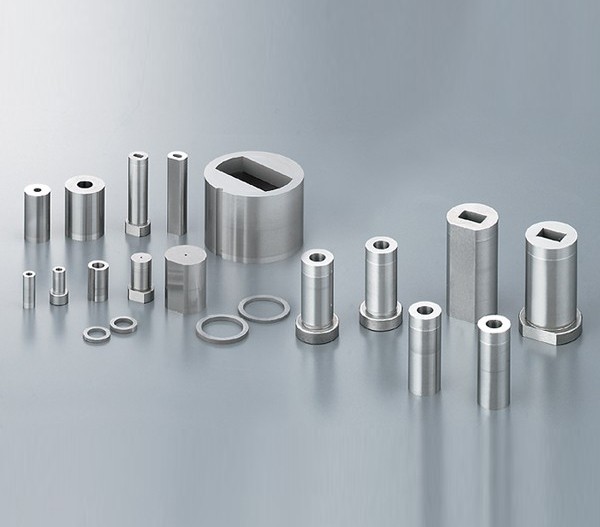

Carbide Dies vs. Steel Dies

Dies play a critical role in various manufacturing processes, especially in metal forming and shaping. Two common types of dies used in these processes are carbide dies and steel dies. Each type has its own set of advantages and disadvantages, making them suitable for different applications. In this comprehensive comparison, we will explore the key differences between carbide dies and steel dies to help you make an informed choice for your specific manufacturing needs.

Table of contents

Material Composition

- Carbide Dies: Carbide dies are made from tungsten carbide, a composite material of tungsten and carbon. It is known for its exceptional hardness and wear resistance. Tungsten carbide can withstand high temperatures and is often used for challenging materials like steel, titanium, and superalloys.

- Steel Dies: Steel dies are typically made from tool steel, which is a high-quality alloy steel designed for cutting and forming applications. Tool steel is known for its strength and toughness but may not have the same hardness and wear resistance as carbide.

Hardness

- Carbide Dies: Carbide dies are extremely hard, ranking among the hardest materials known. This hardness allows them to maintain their shape and cutting edges even when used with abrasive materials. Carbide dies are particularly suitable for high-volume production and long-lasting performance.

- Steel Dies: Steel dies are hard but generally not as hard as carbide. While they can provide excellent performance for many applications, they may wear out faster when subjected to abrasive materials or high-temperature processes.

Wear Resistance

- Carbide Dies: Carbide dies offer exceptional wear resistance, making them ideal for continuous and high-stress operations. They are less prone to wear and deformation, resulting in longer tool life and less downtime for replacement.

- Steel Dies: Steel dies, although durable, may exhibit more wear over time, especially when used with abrasive materials. Frequent maintenance and replacement may be required in high-wear applications.

Heat Resistance

- Carbide Dies: Carbide dies have excellent heat resistance and can maintain their hardness and shape at high temperatures. This property is advantageous for applications involving hot materials or high-speed operations.

- Steel Dies: Steel dies have good heat resistance but may soften or deform at elevated temperatures. For extreme heat applications, carbide dies are often preferred.

Cost

- Carbide Dies: Carbide dies are more expensive to manufacture than steel dies due to the high cost of tungsten carbide. However, their extended lifespan and reduced maintenance costs can make them cost-effective in the long run, especially for high-volume production.

- Steel Dies: Steel dies are generally more cost-effective upfront but may require more frequent replacements and maintenance, increasing operational costs over time.

Application

- Carbide Dies: Carbide dies are well-suited for demanding applications involving abrasive materials, high temperatures, and high-volume production. They are commonly used in industries like automotive, aerospace, and metalworking.

- Steel Dies: Steel dies are versatile and suitable for a wide range of applications, including forming, cutting, and stamping. They are often used in industries like construction, packaging, and general manufacturing.

Precision

- Carbide Dies: Carbide dies can provide high precision and accuracy in forming and cutting operations, making them ideal for intricate and tight-tolerance workpieces.

- Steel Dies: Steel dies can also offer good precision but may have limitations in achieving the same level of accuracy as carbide dies.

the choice between carbide dies and steel dies depends on your specific manufacturing requirements. Carbide dies excel in terms of hardness, wear resistance, and heat resistance, making them suitable for challenging applications. Steel dies are more cost-effective upfront and are versatile for various applications. Understanding your materials, production volume, and operational conditions will help you determine which type of die is the best fit for your needs. Ultimately, both carbide and steel dies play essential roles in modern manufacturing, each offering unique advantages for specific situations.

If you’re interested in exploring the possibilities of using carbide or steel dies in your manufacturing processes or if you have any questions about these die options, don’t hesitate to reach out to us. We offer a wide range of high-quality carbide and steel dies, and our experts are ready to assist you in finding the best solution for your unique requirements. Contact us today to learn more about our die offerings and how they can benefit your operations.