What materials are commonly used for mold springs?

Mold springs are commonly made of chromium alloy steel, known for its high temperature resistance, high rigidity, and long lifespan. Here are the characteristics of four major mold spring materials:

Mold springs are commonly made of chromium alloy steel, known for its high temperature resistance, high rigidity, and long lifespan. Here are the characteristics of four major mold spring materials:

Formula for Calculating Mold Spring Pressure When designing and selecting mold springs, the most fundamental criterion is whether the spring force can ensure smooth production of the mold. The most widely used and critical components in molds are the ejector…

Plastic molds, abbreviated as molds, are a type of composite mold used for compression molding, extrusion molding, injection molding, blow molding, and low-foam molding. The coordinated variation of the mold’s convex and concave molds, along with auxiliary forming systems, can…

Mold springs are widely used mechanical components in molds. They are typically not used independently but serve as auxiliary power for moving components such as ejector plates or core pins. The categories of mold springs can be distinguished by their…

Introduction: Stamping dies play a crucial role in metal forming processes, and determining a safe stamping frequency is vital for maintaining tool longevity and ensuring operational safety. The optimal frequency varies based on several factors, and finding the right balance…

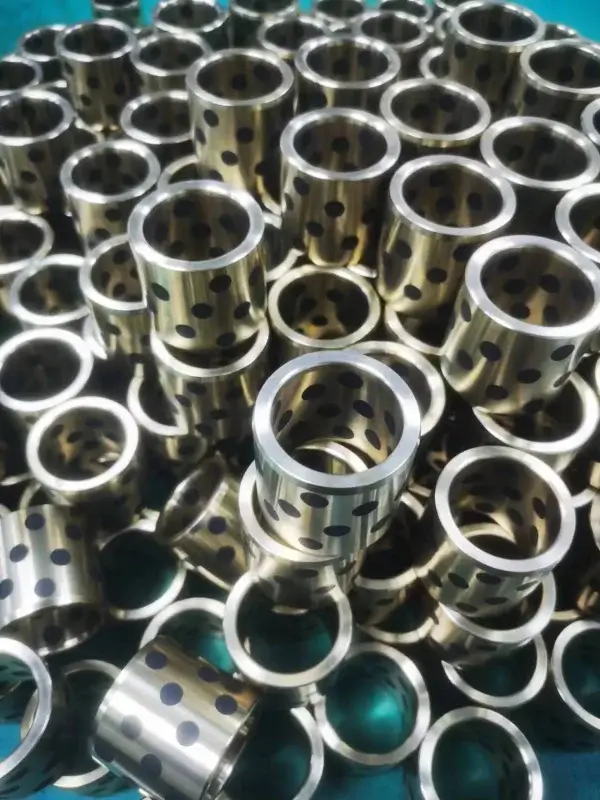

Self lubricating sintered liner is a high porosity (20-25% volume) metal component immersed in lubricating oil. The oil contained in the pores provides continuous lubrication between the bearing and shaft, so the system does not require additional external lubrication.The self-lubricating…

Introduction: Stamping dies and injection molds are crucial tools in the manufacturing industry, each designed for specific processes. One key aspect that sets them apart is the type of parts used in their construction. This article explores the differences in…

In the injection molding process, due to the influence of injection pressure and temperature, the mold may experience displacement during the opening and closing process, leading to deformation and shifting of the internal space. To ensure the normal operation of…

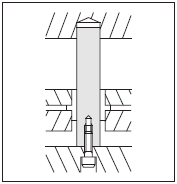

Embedded Type When using the embedded type for the push plate guide pillar, it is necessary to align the guide sleeve hole of the push plate with the embedded hole of the supporting plate (mold) and coordinate for precision processing….

The installation methods for oil-free bearings or oil-free bushings generally involve three approaches: press-fit, interference fit by knocking, and assembly after shrink-fitting. Most Commonly Used Methods: Important Considerations: Ensure these guidelines are followed to maintain the integrity and performance of…

We give value to the excellence and top class engineers, but in terms of accurate service.

Copyright ©Dongguan Gunrui Precision Hardware Co., Ltd. All Rights Reserved