The Precision Fit Between Guide Pillars and Guide Bushings: A Key to Mold Performance

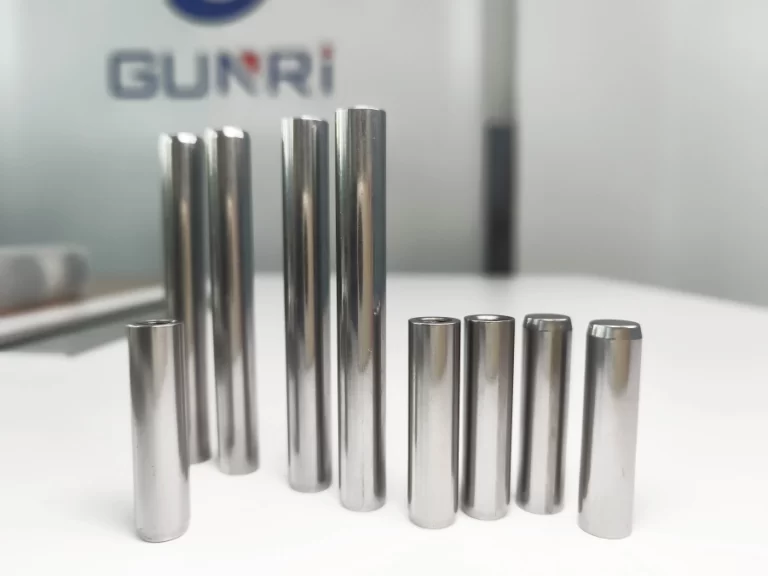

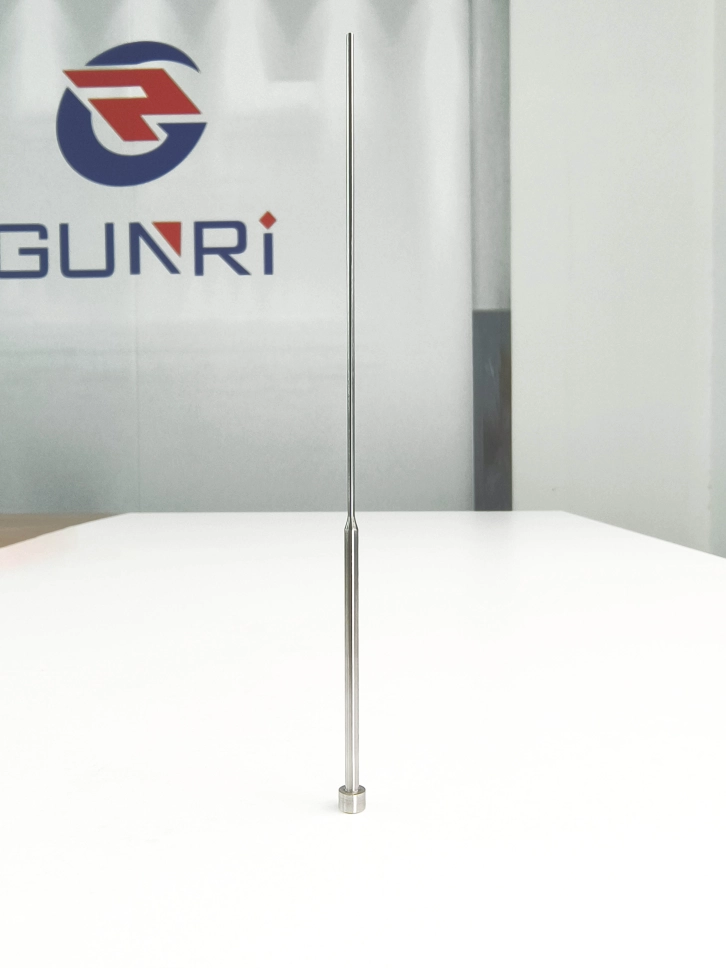

In the realm of mold components, one of the most vital interactions that ensures a mold’s efficiency and precision is the fit between guide pillars and guide bushings. This fit not only contributes to the mold’s stability but also significantly…