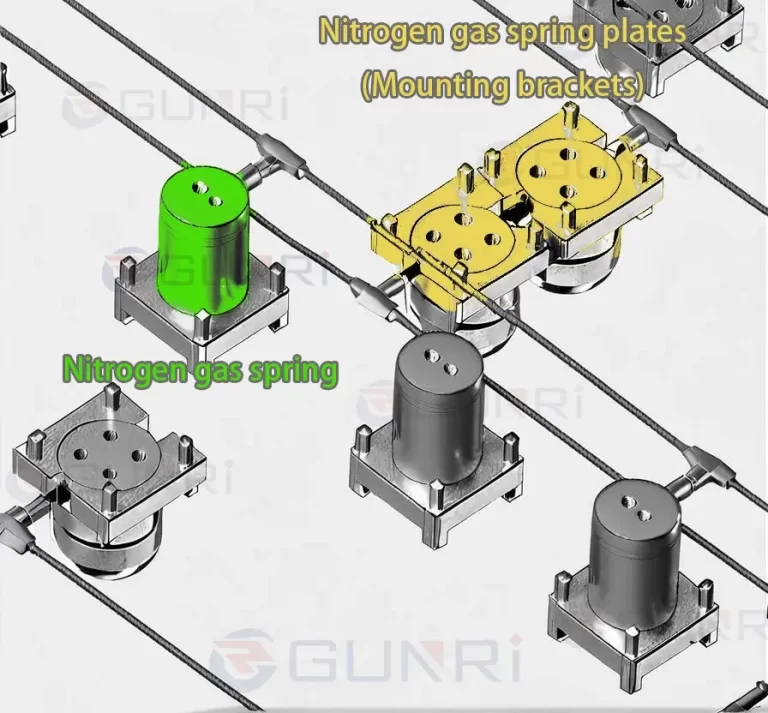

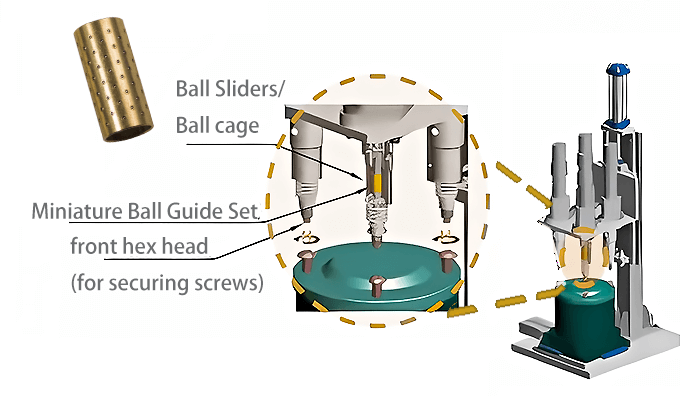

Mounting Brackets for Gas Springs: Essential Components for Optimal Performance

Gas springs, often filled with nitrogen gas, are vital in numerous industrial and mechanical applications, providing a reliable and efficient means of controlling motion and force. However, their performance is significantly influenced by the mounting brackets that secure them in…