Navigating the Challenges of Mexico’s Mold Manufacturing Industry: Strategies for Quality and Cost Efficiency

Challenges Facing the Mexican Mold Manufacturing Industry

The mold manufacturing industry in Mexico has grown significantly over the past decade, driven largely by demand from the automotive, electronics, and consumer goods sectors. Yet, despite this growth, persistent challenges still exist that could limit the industry’s potential. From labor shortages to technological gaps and increasing production costs, Mexican manufacturers face hurdles that require both short-term solutions and long-term strategy. Here, we’ll explore these challenges and offer insight into one effective sourcing approach for critical components.

Labor Shortages and Skill Development

A shortage of skilled labor has become a pressing issue in Mexican manufacturing. Companies like Ramirez Mold Solutions, a mid-sized firm based in Monterrey, have faced difficulties finding qualified technicians, mold designers, and machinists to handle specialized tasks. This shortage not only limits the company’s production capacity but also impacts project timelines. Ramirez’s owner, Juan, attempted to train employees in-house, yet many moved to higher-paying positions in different industries. This trend is not unique—around 60% of Mexican manufacturers cite labor shortages as a significant barrier to growth.

To address this, industry leaders are now advocating for more robust vocational training programs in partnership with schools and other companies, which could make manufacturing careers more attractive to young people, helping sustain the industry in the long run.

Technological Limitations

Although the global manufacturing sector has seen technological advancement, many smaller Mexican manufacturers still rely on aging machinery. This impacts production speed and precision, and results in higher maintenance costs over time. Ramirez Mold Solutions, for instance, continues to use a CNC machine that is over 15 years old, which limits their productivity and precision. Newer equipment would improve efficiency, but the high upfront cost makes it a challenging investment for many businesses.

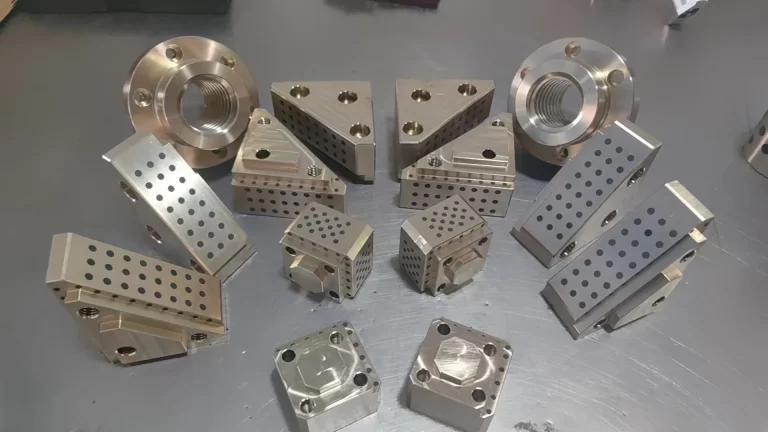

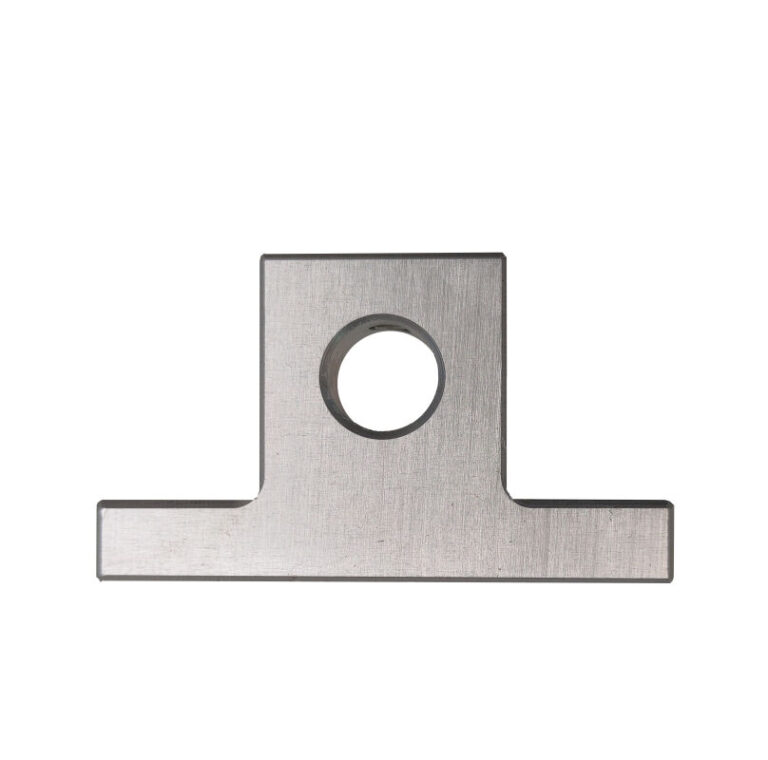

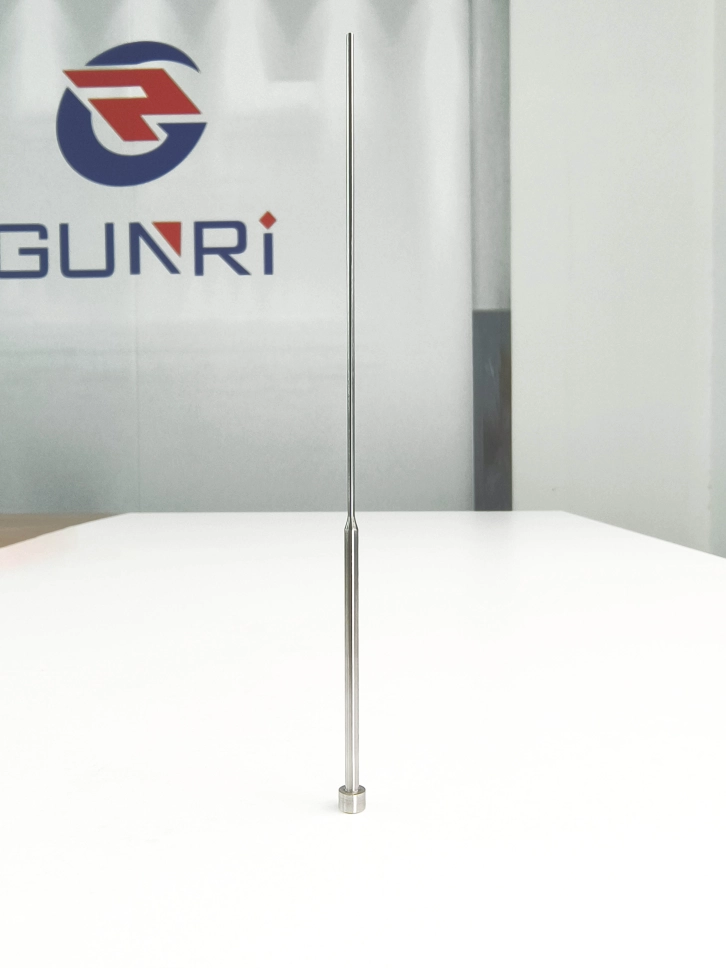

Sourcing High-Quality Components

Quality component sourcing presents another complex challenge, especially for critical parts like punch pins. Local suppliers may sometimes fall short on quality, leading Mexican manufacturers to seek alternatives that meet their standards for durability and precision. After struggling with quality inconsistencies from local sources, Ramirez Mold Solutions turned to an international option, choosing to source punch pins from GUNRI, a Chinese supplier known for high standards. The reliable quality of GUNRI’s products allowed Ramirez to reduce defect rates, helping them maintain their product quality without increasing costs.

Rising Production Costs

In addition to labor and sourcing challenges, production costs in Mexico are steadily rising. In recent years, material prices have climbed by nearly 20%, while energy costs have seen an increase of more than 15%. These rising costs make it difficult for companies like Ramirez Mold Solutions to remain competitive, as they must continually adjust prices and operations to absorb these increases.

The Path Forward

For the Mexican mold manufacturing industry to continue thriving, companies need a proactive approach to overcoming these challenges. Strategies such as creating in-house training programs, exploring technology upgrades, and finding reliable international suppliers for essential components can empower manufacturers to improve efficiency and product quality. With these solutions in mind, Mexican mold manufacturers will be well-positioned to grow sustainably in an increasingly competitive global market.