Characteristics of Mold Component Manufacturing

- Shortened Manufacturing Cycle

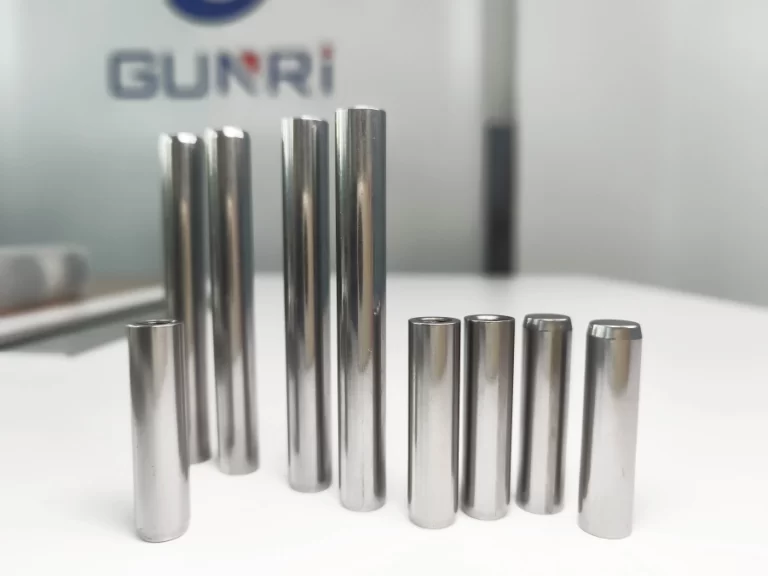

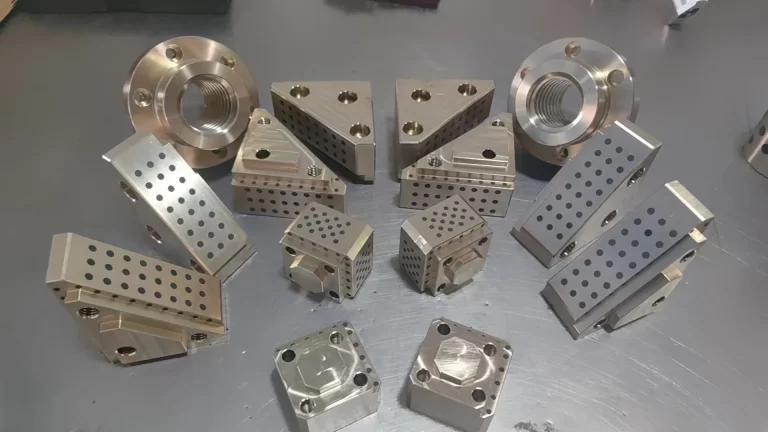

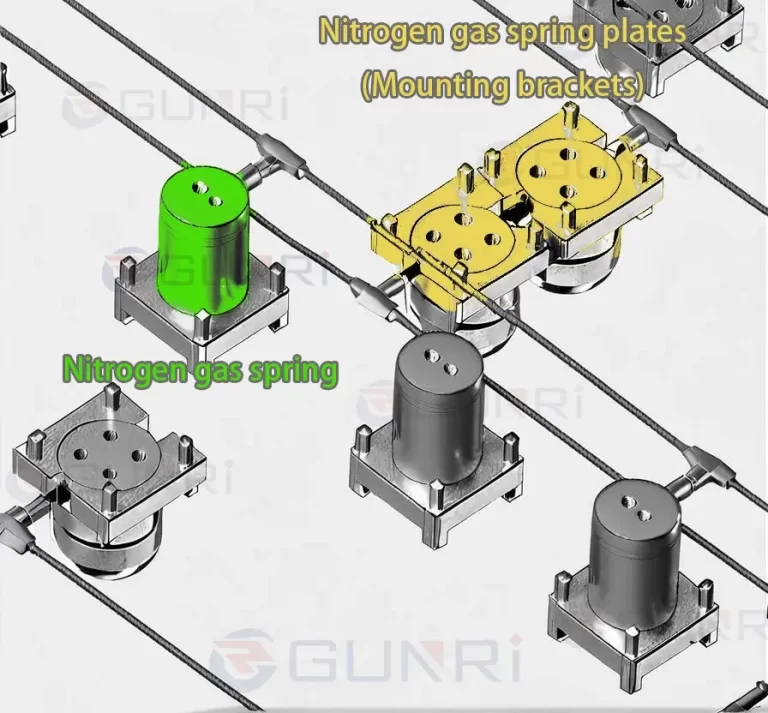

With the development cycle for new products becoming increasingly shorter, the mold development cycle has also significantly reduced. This requires the entire mold manufacturing process, from quotation to design and production, to respond swiftly. To meet customer demands, the manufacturing process must be fast and efficient. Additionally, mold shapes are often highly complex, with working parts typically featuring intricate three-dimensional or two-dimensional curved surfaces, rather than simple geometric shapes found in conventional machining.

- High Manufacturing Quality Requirements

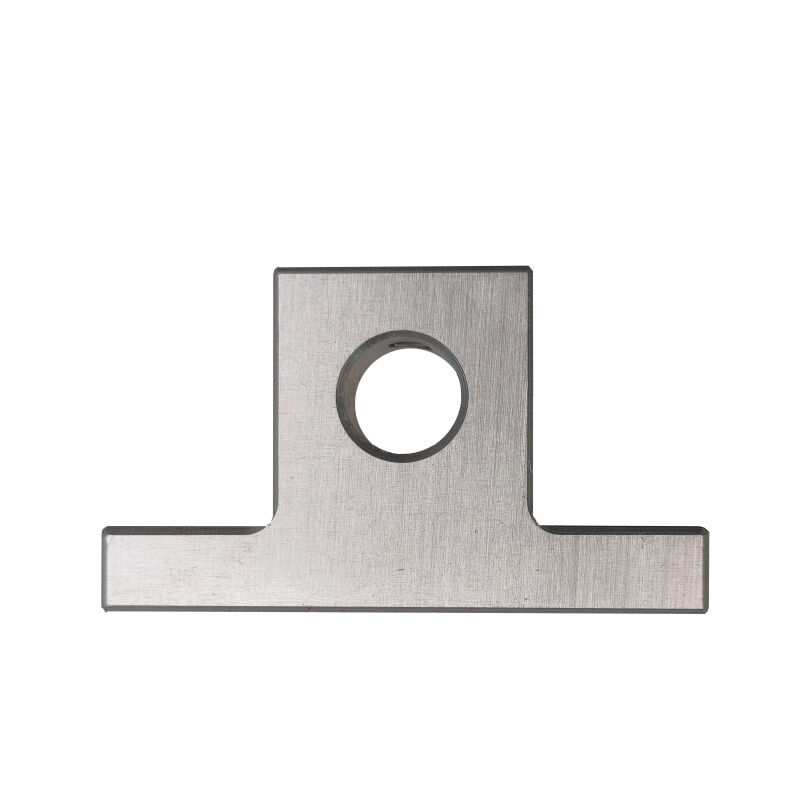

Mold manufacturing demands not only high machining precision but also superior surface quality. The structure of molds is often variable and must be designed according to the shape and structural elements of the components they will produce. Because the products formed by molds are frequently new, there are often modifications required during the mold development process. After trial molding, adjustments to the product’s shape or structure may be necessary, necessitating further reprocessing.

In conclusion, the characteristics of mold component manufacturing include a shortened production cycle and stringent quality requirements. The complexity of mold shapes and the necessity for precise, high-quality manufacturing make this field particularly challenging, requiring rapid adaptation to new developments and changes in product design.