Choosing the Right Material for Guide Pillars and Bushings in Molds

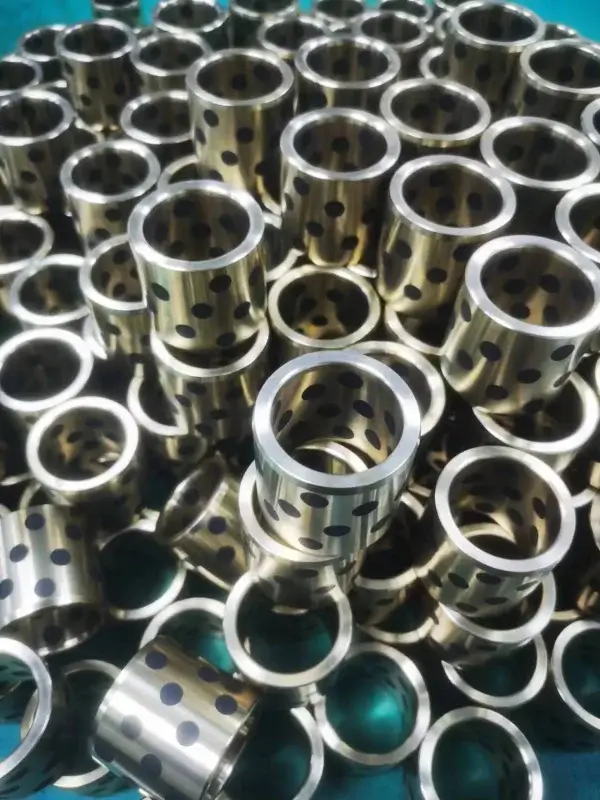

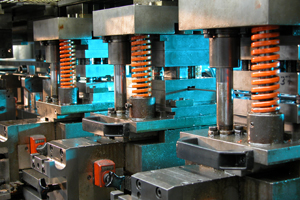

In the production process of various molds, one essential component is the guide pillars and bushings, which form the guiding mechanism ensuring the smooth opening of moving and fixed mold components. The market offers a wide variety of guide pillar and bushing options, making the selection of material and dimensions a crucial consideration.

Table of contents

Understanding the Performance of Common Guide Pillar and Bushing Materials

To start, it is important to grasp the performance characteristics of commonly used materials. One such material is SUJ2, a high-carbon chromium bearing steel following the Japanese JIS standard, corresponding to the national standard designation GCr15. SUJ2 can undergo full hardening with a hardness reaching HRC58-61. It boasts exceptional wear resistance, strengthening steel properties, and can be directly machined with a mold life exceeding that of SKD-61 (HRC52) by 2-3 times. SUJ2 exhibits minimal dimensional changes during quenching and tempering, coupled with excellent fatigue resistance. Widely applied in molds, automotive components, machine tool bearings, steel balls, rollers, and shaft sleeves, SUJ2 is the material of choice in high-load conditions, providing enhanced stability.

Choosing the Appropriate Guide Pillar and Bushing Material

The selection of guide pillar and bushing material should align with the specific requirements of the operating environment. While SUJ2 is preferred for its stability under high loads, the choice must consider the overall working conditions and the need for wear resistance, strength, and stability.

Ensuring Quality in Guide Pillars and Bushings

Beyond material considerations, the quality of guide pillars and bushings is paramount. Optimal quality ensures an extended lifespan for molds and reduces maintenance costs. Investing in high-quality guide pillar and bushing components contributes to the overall efficiency and reliability of mold operations.

In conclusion, the selection of guide pillar and bushing materials plays a pivotal role in the performance and longevity of molds. A comprehensive understanding of material properties, coupled with a keen focus on quality, ensures that guide pillars and bushings meet the specific demands of diverse working conditions, ultimately guaranteeing stable mold operation and prolonged service life.