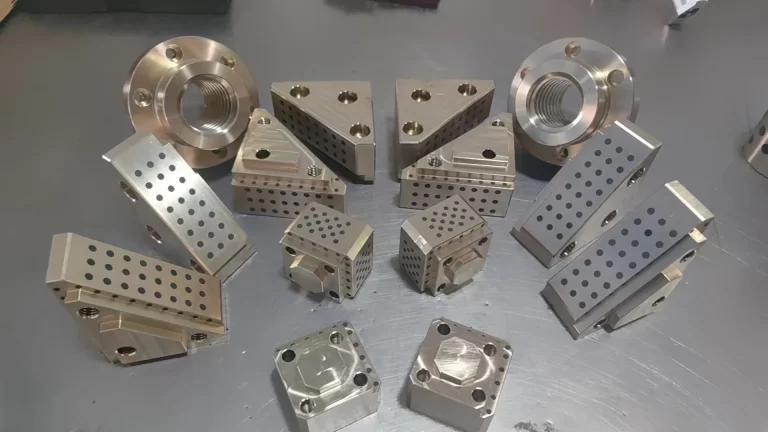

Common Mold Standard Parts: Understanding Mold Accessories

In the world of molds, various standard components are crucial for ensuring precision and efficiency in the manufacturing process. Let’s explore the commonly used mold standard parts, including mold frames (for cold stamping, plastic, and die-casting molds), guiding components (guide pins, guide bushings, guide plates, punch guide pins, punch guide bushings), positioning elements (pins, conical positioning pins, wedge-shaped positioning blocks), ejector pins and sleeves (circular, irregular, straight push, stepped), elastic elements (circular compression springs, rubber springs), small standard components (gate sleeves, locating rings, hooks, screws, unloading pins, limiting pins), hot runner systems, standard components (die quick-change devices, feed components, side punching devices), and other standard parts.

Table of contents

1. Guiding Components

Guiding components play a crucial role in providing guidance within the mold. These include guide plates, guide pins, and guide bushings.

- Guide Plates

- A is used for guiding components with significant lateral forces, such as guiding between upper and lower molds, and guiding between pressure plates and concave-convex molds.

- Large guide plates are suitable for guiding between upper and lower molds, typically in two forms: single-head guiding, installed on the upper mold to guide the upper mold with the lower mold; double-head guiding, installed on the edge ring for compound guiding.

- Guide Pins and Guide Bushings

- Guide pins and guide bushings are always used as a set, suitable for molds with higher requirements for guiding precision than guide plates. In automotive molds, they are generally not used separately (except for blanking molds). Due to the high lateral force in automotive stamping molds, they require compound guiding combined with guide plates for enhanced precision.

- Guide Plates for Inclined Wedges

- Used for guiding between the slider and slider seat.

- Used for guiding between the slider and inclined wedge driving block.

- Provides guiding and limiting functions for lateral pressure plates.

2. Positioning Components

Positioning components serve to position the mold and workpieces. These include positioning plates, feed plates, positioning pins, keys, guide pins, etc.

- Used for positioning between workpieces and molds

- A, Positioning plates (material positioning frame): Mainly used for material positioning in drawing molds or blanking molds. Positioned inside the mold, outside the workpiece.

- B, Feed Plate: Mainly used for initial guidance in blanking molds or progressive dies.

- C, Positioning pins or guide pins: The main function is to position parts inside the mold (already punched).

- D, Pneumatic material stop device: Mainly suitable for semi-automatic stamping lines, one of the devices that automatically discharges the material after manual feeding.

- E, Feeding detection device.

3. Stamping Components

Die, punch, stripper plate, mold frame, independent guide pillar, top rod, top needle, push rod, guide pin, stamping head fixing seat, etc.

4. Elastic Elements

For machine tools, which can only generate significant forces, elastic elements are crucial for completing stamping actions. When components within the mold require relatively small forces, elastic elements are used to generate the forces needed to complete actions.

Elastic elements mainly include springs, polyurethane, nitrogen cylinders, pull springs, nitrogen springs, etc.

This comprehensive guide aims to provide a deeper understanding of common mold standard parts and accessories, ensuring precision and efficiency in mold manufacturing processes.