Comparing Bushings vs Ball Bearings: Understanding the Distinctions

In this article, we will take a closer look at the differences between bushings and ball bearings, two essential components commonly used in various industries and applications. Understanding their characteristics, applications, and advantages can help you make informed decisions when choosing between them for your specific needs.

Table of contents

Introduction

In industries spanning from machinery to aerospace, linear motion systems rely heavily on components like bushings (also known as sleeve bearings) and ball bearings. These components play critical roles in reducing wear, extending service life, minimizing noise, and optimizing power consumption. Whether in machinery, high-speed applications, automotive projects, or aerospace ventures, both bushings and ball bearings have vital contributions to make.

Bushing vs. Ball Bearing: A Quick Overview

| Bushings | Ball Bearings | |

|---|---|---|

| Friction | Higher friction, suitable for minor misalignments | Lower friction, designed for heavy and high axial loads |

| Lateral Force | Not intended for high lateral forces | Can handle significant axial and radial loads and forces |

| Materials | Common materials include bronze, alloys, graphite, stainless steel | Available in various materials, including plastic and ceramic |

| Lubrication | Impregnated with oil for self-lubrication | Require external lubrication and periodic maintenance |

| Tolerances | Built with tighter tolerances for a snug fit | Wider tolerances that can impact fit on smooth rods |

| Maintenance | Generally require less maintenance | Require more maintenance due to lubrication and wear |

| Noise | Quieter, especially at low and high speeds | Generally noisier than bushings at both speeds |

What Is a Bushing?

A bushing is a thin tube used in machinery with sliding or rotating shafts to reduce noise, vibration, and inefficiency. Commonly found in vehicles, motors, hydraulic gear pumps, and more, bushings act as a critical element for smoother operation and performance enhancement. Despite being technically a bearing type, they function as single components rather than moving between two parts.

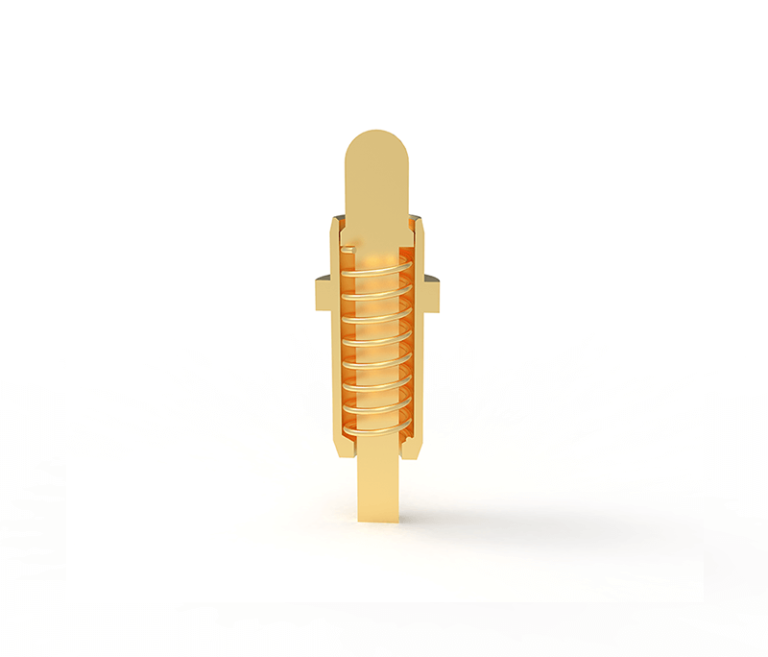

What Is a Ball Bearing?

A ball bearing is a type of rolling-element bearing designed to carry radial loads, reduce friction, and maintain the positioning of moving machine parts. Different ball bearing designs cater to specific load capacities and applications, including angular contact bearings, thrust bearings, deep-groove bearings, linear bearings, high-speed angular contact bearings, and self-aligning bearings.

Which Is Better to Use – Ball Bearings or Bushings?

After gaining a comprehensive understanding of both bushings and ball bearings, it’s crucial to assess which is more suitable for your project’s requirements. There are compelling reasons to consider both:

- Bushing Advantages:

- Self-lubrication: Once impregnated with oil, bushings provide ongoing lubrication.

- Cost-effectiveness: Bushings are more budget-friendly compared to ball bearings.

- Quieter operation: Bushings typically offer quieter performance, especially in comparison to poorly maintained bearings.

- Reduced maintenance: With their self-lubricating properties, bushings demand less frequent maintenance.

Both bushings and ball bearings have their merits, making your decision contingent on factors such as load capacities, noise considerations, budget constraints, and required maintenance. By understanding their distinctions, you can confidently choose the component that aligns best with your project’s needs.