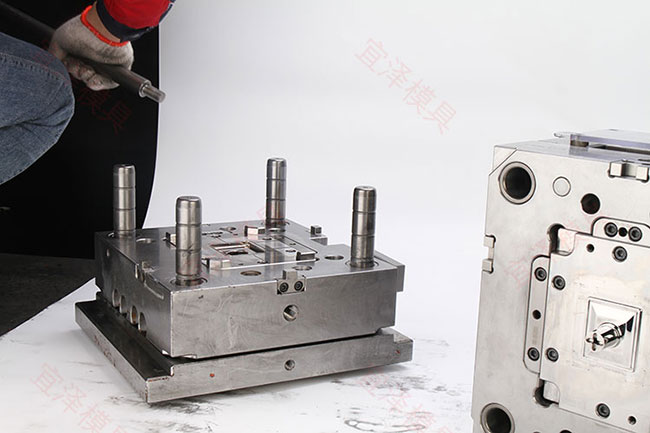

Completion of -190°C Cryo-Treated Guide Pins & Bushings

We are pleased to announce the successful completion of our latest batch of precision guide pins and bushings, having undergone a rigorous ultra-deep cryogenic treatment at an extreme -190°C. This advanced thermal processing represents a significant step forward in component longevity and reliability for demanding industrial applications.

The Science of Ultra-Deep Cryogenics

Unlike standard sub-zero treatments, our -190°C cryogenic process meticulously transforms retained austenite into martensite within the steel’s microstructure. This is followed by a specialized tempering cycle that refines the newly formed structure. The result is a comprehensive stabilization of the metal, leading to profound improvements in the component’s fundamental properties.

Key Benefits for Your Operations:

Superior Wear Resistance: Components exhibit a noticeably harder surface, dramatically reducing wear and tear from continuous operation.

Unmatched Dimensional Stability: The deep cryogenic process permanently relieves internal stresses, minimizing microscopic distortions and ensuring consistent performance and fit over time.

Extended Service Life: By enhancing the material’s core integrity, these treated guide pins and bushings offer a significantly longer operational lifespan, reducing downtime and frequency of replacement.

Ideal for Precision Applications

These cryo-treated components are engineered for the most challenging environments, including:

High-speed precision stamping dies

Injection molds requiring utmost accuracy

Automated assembly systems and precision machinery

The completion of this batch marks our ongoing commitment to delivering not just components, but engineered solutions that drive efficiency and productivity for our clients.

Explore how our -190°C cryo-treated guide pins and bushings can enhance your tooling performance. Contact our technical team today for more information and specifications.