Comprehensive Guide to Punch & Die Types for Metal Stamping

In metal stamping, the design and selection of punches and dies determine the accuracy, efficiency, and versatility of the forming process. Each punch and die type serves a specific purpose—whether for creating complex hole patterns, achieving smooth edges, or adapting to unique material shapes. Below is an overview of common punch & die types used across industrial and structural metal fabrication.

1. Multi-Hole and Cluster Punches

5-Hole Unistrut and Cluster Punch tools are designed to create multiple holes in a single stroke, improving production efficiency and maintaining consistent spacing. These are commonly used in structural framing, channel fabrication, and electrical support systems where repetitive patterns are required.

2. Profile and Edge Forming Tools

Corner Radius punches smooth out sharp edges, preventing material stress and improving the final appearance.

Countersink punches are used when a conical recess is needed—typically for flat-head screws or bolt seating.

Double Step and Gauge Line Flat punches help maintain dimensional consistency along critical alignment lines or stepped profiles.

3. Shearing and Combination Tools

Double Punch & Shear and Single Punch & Shear are combination tools capable of both cutting and punching in one operation. This integrated design reduces setup time and increases throughput, particularly useful for sheet and channel production lines.

4. Specialized Structural Punches

Guardrail Punch tools are made for punching mounting holes in safety barriers and highway guardrails.

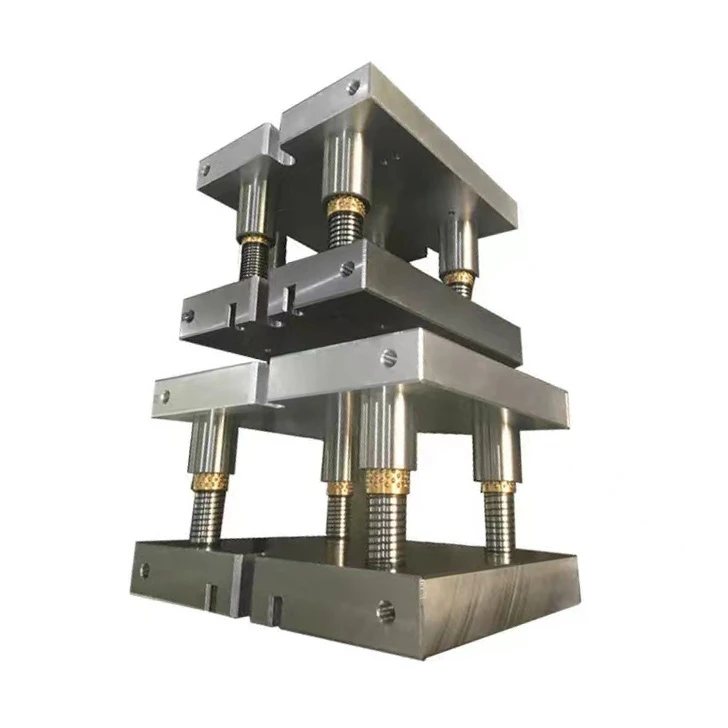

Offset Dies allow for punching on irregular or offset planes without deforming the workpiece—ideal for formed parts.

Round Pipe Mandrel and Square Tube Mandrel tools are engineered to support hollow sections internally during punching, ensuring roundness and preventing collapse.

5. Shaped and Application-Specific Punches

Keyhole punches produce slots that allow easy assembly and disassembly in mechanical or mounting applications.

Star Punch tools form decorative or functional multi-point holes often used for ventilation or design features.

Ripping Punch tools are built for high-force tearing or slot-cutting operations where standard punches would wear out quickly.

6. Advanced Coatings and Materials

The MG2 Coated Punch represents modern advancements in tool coating technology. Its enhanced surface hardness and friction resistance greatly improve tool life and reduce maintenance frequency, making it ideal for high-volume production environments.

Conclusion

Each punch and die type brings unique advantages tailored to specific manufacturing needs. From multi-hole efficiency to precision countersinking and advanced coatings, the right tooling ensures superior part quality and productivity.

If you’d like to learn more about these Punch & Die Types or customize tooling for your application, contact us — we are a professional punches and dies manufacturer.