Custom DIN 7979 Dowel Pins: The Ultimate Guide

When it comes to precision engineering and assembly, custom DIN 7979 dowel pins play an indispensable role. These cylindrical fasteners are designed to maintain accurate alignment of machine components, ensuring stability and performance. In this comprehensive guide, we will delve into the specifics of custom DIN 7979 dowel pins, exploring their applications, benefits, materials, and customization options to help you make informed decisions for your projects.

Table of contents

- What Are DIN 7979 Dowel Pins?

- Applications of Custom DIN 7979 Dowel Pins

- Benefits of Using Custom DIN 7979 Dowel Pins

- Materials Used in Custom DIN 7979 Dowel Pins

- Customization Options for DIN 7979 Dowel Pins

- Manufacturing Process of Custom DIN 7979 Dowel Pins

- Selecting the Right Custom DIN 7979 Dowel Pins

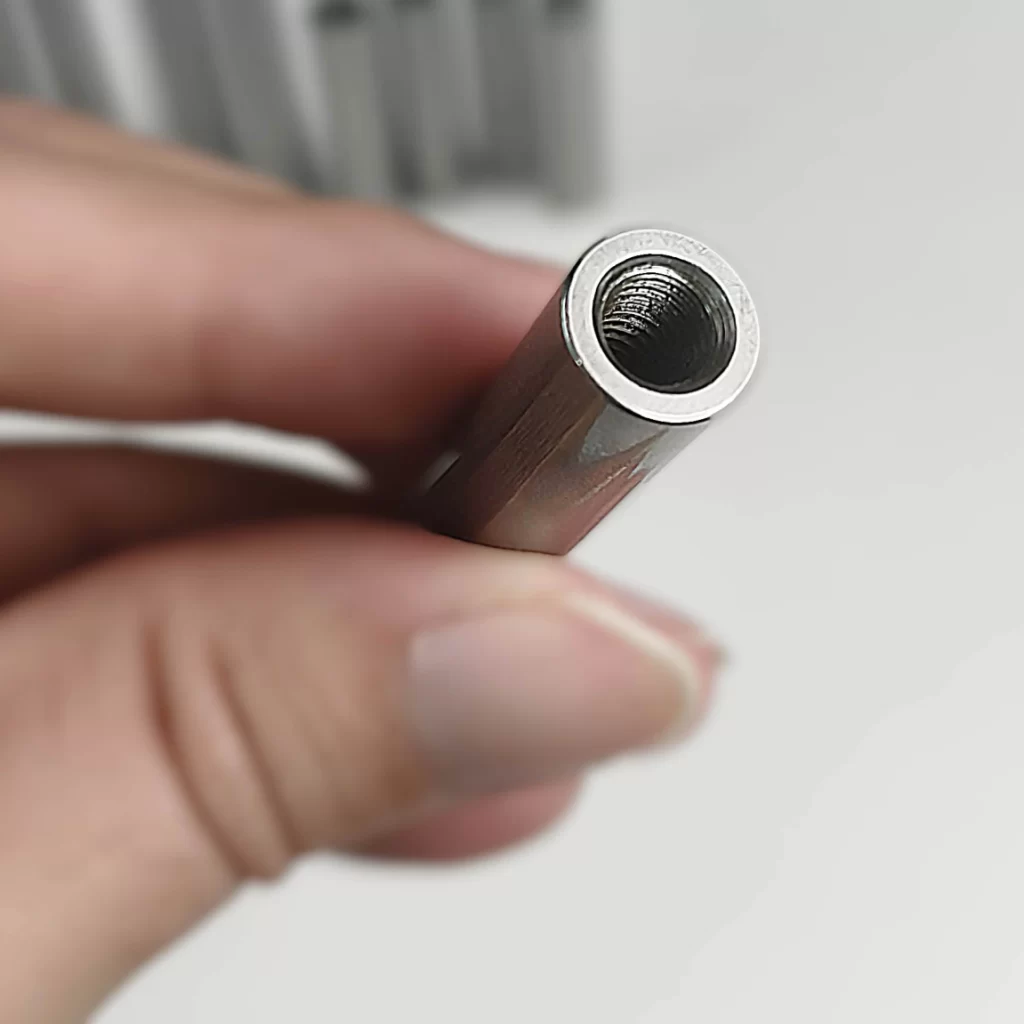

What Are DIN 7979 Dowel Pins?

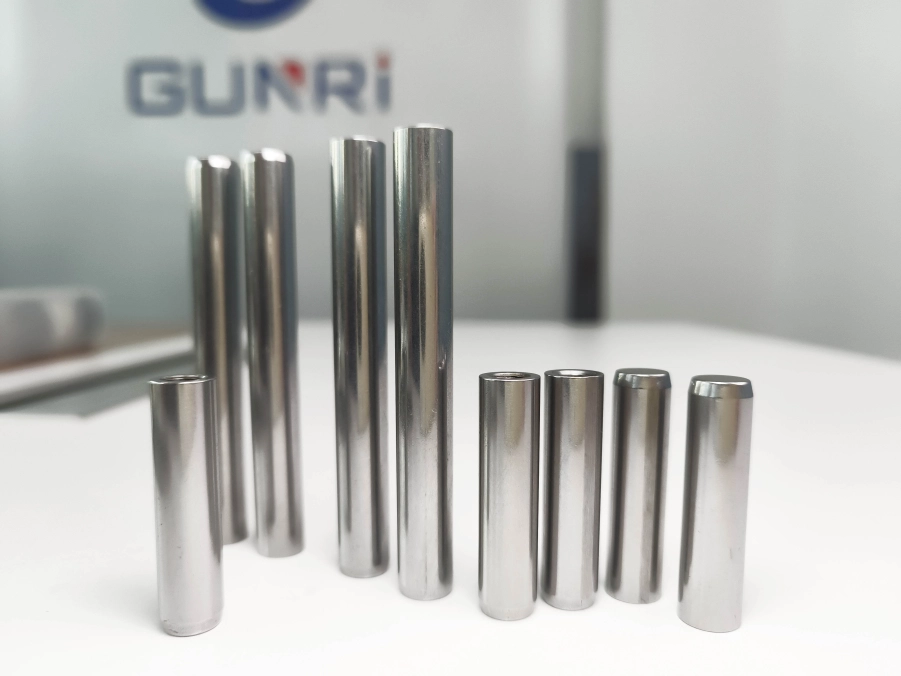

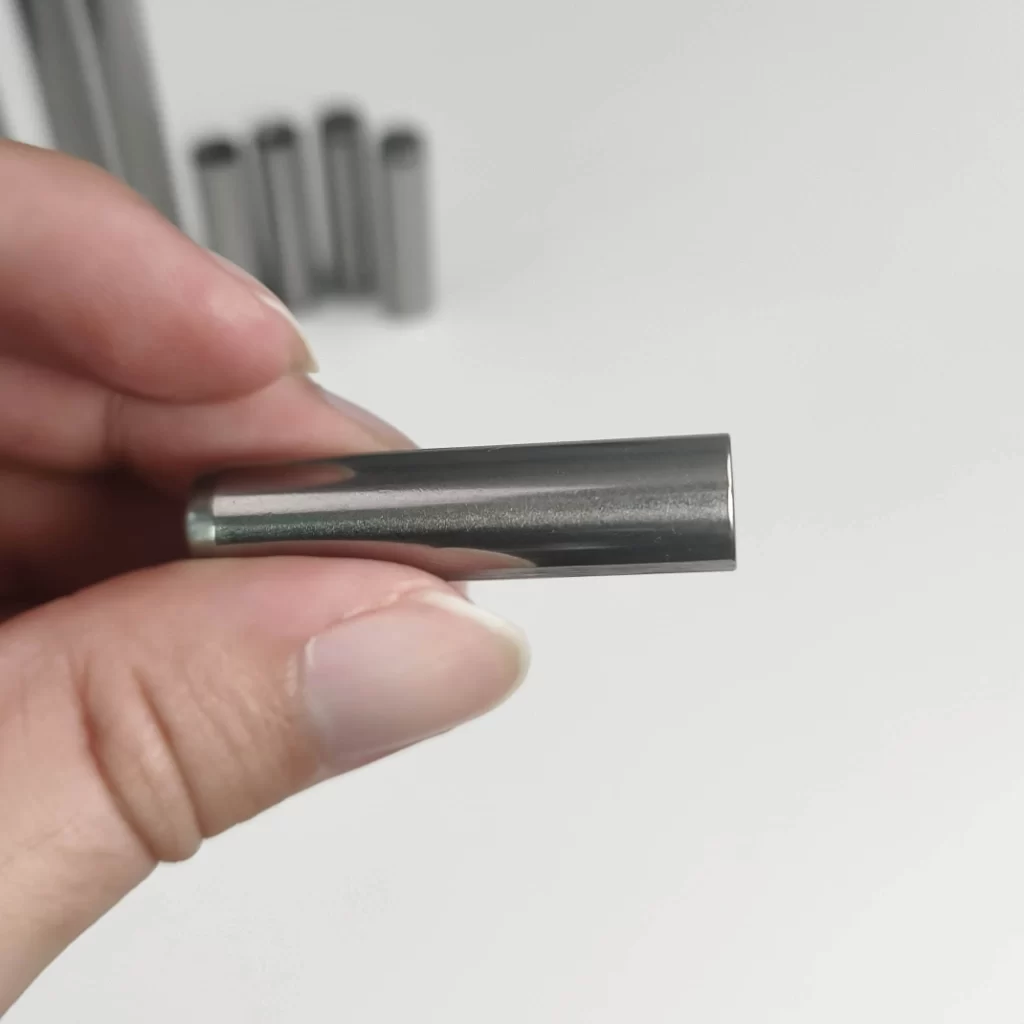

DIN 7979 dowel pins are standardized pins used primarily for precise alignment in mechanical assemblies. They adhere to the specifications set by the Deutsches Institut für Normung (DIN), ensuring consistent quality and dimensions. These dowel pins are characterized by their cylindrical shape and chamfered ends, which facilitate easy insertion into pre-drilled holes.

Applications of Custom DIN 7979 Dowel Pins

Custom DIN 7979 dowel pins are utilized across a wide range of industries due to their ability to provide precise alignment and secure positioning. Some common applications include:

- Automotive Industry: Custom DIN 7979 dowel pins are used to ensure the accurate alignment of engine components and transmission parts, which is crucial for vehicle performance and safety.

- Aerospace Industry: In the aerospace sector, these dowel pins are employed to maintain the precise assembly of critical aircraft components, essential for flight safety and mechanical performance.

- Manufacturing: In manufacturing, custom DIN 7979 dowel pins align various machine parts to ensure operational efficiency and reduce wear, significantly improving production efficiency and reducing maintenance costs.

- Robotics: In the field of robotics, custom dowel pins ensure the stability and precise positioning of robotic joints and parts, which is vital for the flexibility and reliability of robots.

- Medical Devices: Custom DIN 7979 dowel pins are used to assemble precise medical instruments and equipment, ensuring the accuracy and reliability of the devices.

- Mechanical Components: Elesa+Ganter provides DIN 7979 dowel pins that can be used with various mechanical components, such as screws, washers, and nuts, to achieve high-precision positioning and fastening.

- Automation and Assembly Equipment: Custom DIN 7979 dowel pins are also widely used in automation equipment and assembly lines to ensure precise alignment and fastening of components, improving assembly efficiency and product quality.

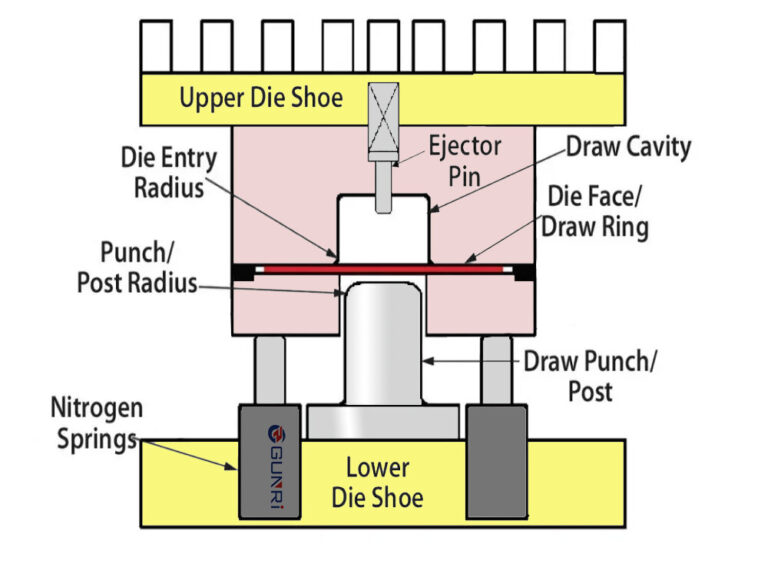

- Mold Manufacturing: In the mold manufacturing industry, custom dowel pins are used to precisely position mold components, ensuring accurate fit and stable operation of the molds.

Benefits of Using Custom DIN 7979 Dowel Pins

The use of custom DIN 7979 dowel pins offers numerous advantages, making them a preferred choice in precision engineering:

- Enhanced Accuracy: Their precise dimensions ensure accurate alignment of parts, reducing the risk of misalignment and associated issues.

- Improved Stability: By providing a secure and stable connection, these dowel pins minimize movement between components.

- Ease of Assembly: The chamfered ends facilitate easy insertion, simplifying the assembly process.

- Versatility: Available in various materials and sizes, they can be customized to suit specific requirements.

- Durability: Made from high-quality materials, these dowel pins offer excellent wear resistance and longevity.

Materials Used in Custom DIN 7979 Dowel Pins

Custom DIN 7979 dowel pins can be manufactured from a variety of materials, each offering unique properties to meet different application needs:

Stainless Steel

Stainless steel dowel pins are highly durable and resistant to corrosion, making them ideal for applications in harsh environments or where hygiene is critical, such as in the food and pharmaceutical industries.

Carbon Steel

Carbon steel dowel pins provide excellent strength and wear resistance, making them suitable for heavy-duty applications. They can also be heat-treated to enhance their mechanical properties.

Alloy Steel

Alloy steel dowel pins offer a balance of strength, toughness, and corrosion resistance. They are commonly used in applications requiring high performance under varying conditions.

Brass

Brass dowel pins are known for their good corrosion resistance and electrical conductivity. They are often used in applications where non-magnetic properties are important.

Plastic

Plastic dowel pins are lightweight and resistant to corrosion and chemicals. They are suitable for applications where metal pins could cause damage or interference.

Customization Options for DIN 7979 Dowel Pins

To meet specific project requirements, custom DIN 7979 dowel pins can be tailored in various ways:

Dimensional Customization

Length and Diameter: Custom dowel pins can be manufactured to specific lengths and diameters to fit precise requirements, ensuring optimal performance.

Surface Treatments

Coating and Plating: Surface treatments such as zinc plating, black oxide coating, or anodizing can be applied to enhance corrosion resistance, wear resistance, and aesthetic appeal.

Tolerance Levels

Precision Machining: Custom dowel pins can be machined to tighter tolerances to ensure a perfect fit, critical for high-precision applications.

Special Features

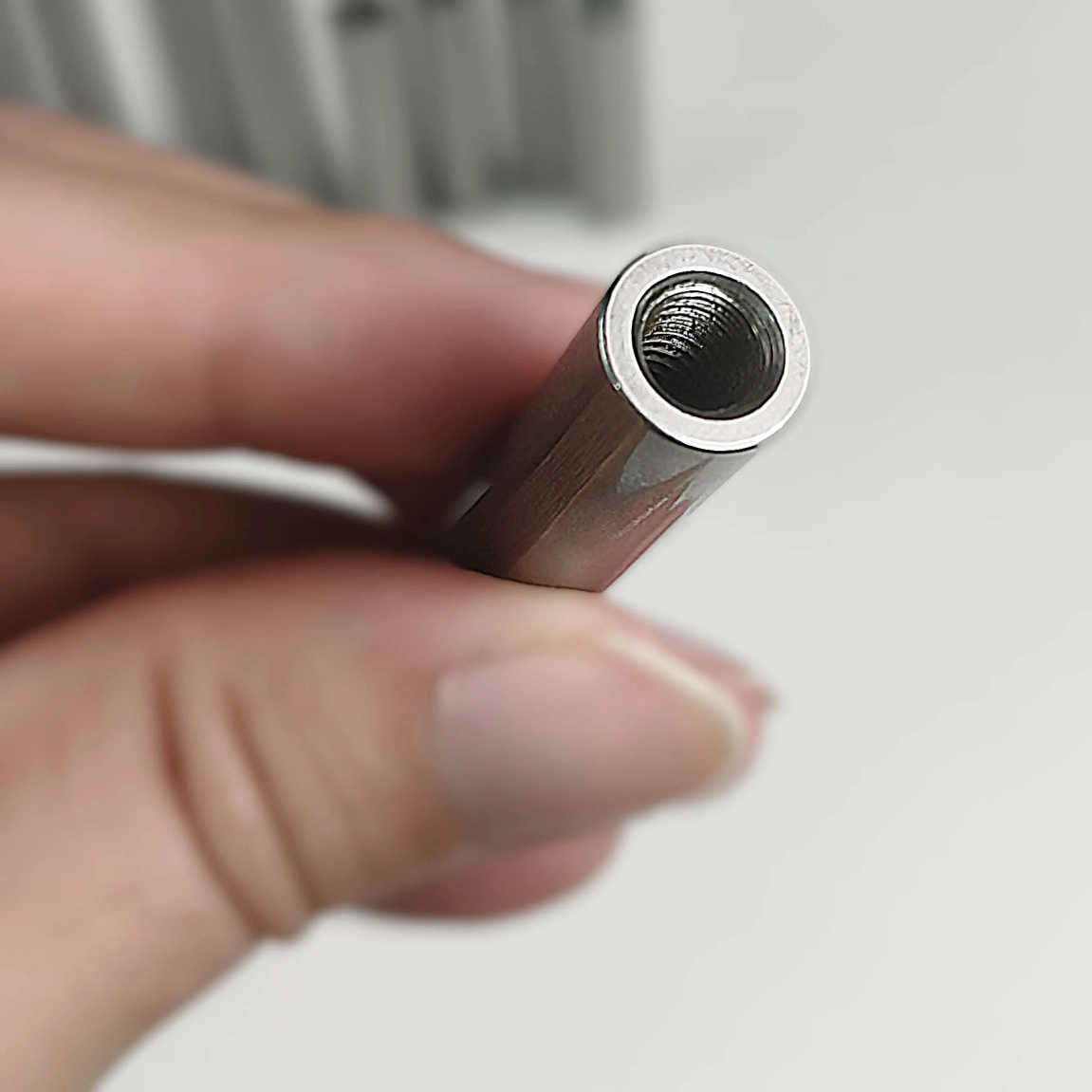

Threaded Ends: Adding threads to one or both ends of the dowel pin can facilitate easy removal or secure fastening. Custom Chamfers: Tailoring the chamfer angles can improve ease of assembly and alignment accuracy.

Manufacturing Process of Custom DIN 7979 Dowel Pins

The manufacturing process of custom DIN 7979 dowel pins involves several key steps to ensure high quality and precision:

Material Selection

Choosing the appropriate material based on the application requirements is the first step. Factors such as strength, corrosion resistance, and machinability are considered.

Cutting and Shaping

The selected material is cut to the desired length and shaped into a cylindrical form. This step may involve processes such as turning, milling, or grinding.

Heat Treatment

Heat treatment processes, such as quenching and tempering, are applied to enhance the mechanical properties of the dowel pins, such as hardness and strength.

Surface Finishing

Surface treatments, such as polishing, coating, or plating, are applied to improve the durability and appearance of the dowel pins.

Quality Inspection

Each dowel pin undergoes rigorous quality checks to ensure it meets the required specifications and tolerances. This may involve dimensional checks, hardness testing, and visual inspections.

Selecting the Right Custom DIN 7979 Dowel Pins

Choosing the right custom DIN 7979 dowel pins for your application involves considering several factors:

Application Requirements

Assess the specific needs of your application, including load-bearing capacity, environmental conditions, and required tolerances.

Material Properties

Select a material that offers the necessary strength, corrosion resistance, and other relevant properties for your application.

Dimensional Accuracy

Ensure the dowel pins are manufactured to precise dimensions and tolerances to guarantee accurate alignment and fit.

Surface Treatments

Consider any additional surface treatments that may be required to enhance the performance and longevity of the dowel pins.

Conclusion

Custom DIN 7979 dowel pins are essential components in precision engineering and assembly, offering unparalleled accuracy and stability. By understanding their applications, benefits, materials, and customization options, you can make informed decisions to ensure the success of your projects. Whether you need dowel pins for automotive, aerospace, manufacturing, robotics, or medical devices, opting for custom solutions tailored to your specific requirements will provide optimal performance and reliability.

For more information or to discuss your specific needs for custom DIN 7979 dowel pins, please contact GUNRI.