Custom Roller Guide Post Sets for Die Sets: Rollers Maintain Zero Contact

Roller Guide Post Sets, also known by various names such as Guide Unit with collar, MILLIONGUIDE, and needle roller guide posts in different countries and regions, play a crucial role in mold manufacturing. They ensure high precision and low friction during operation.

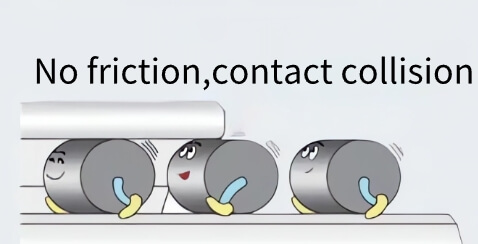

Due to their unique structure, these guide posts can achieve zero contact among rollers, significantly reducing friction and enhancing performance.

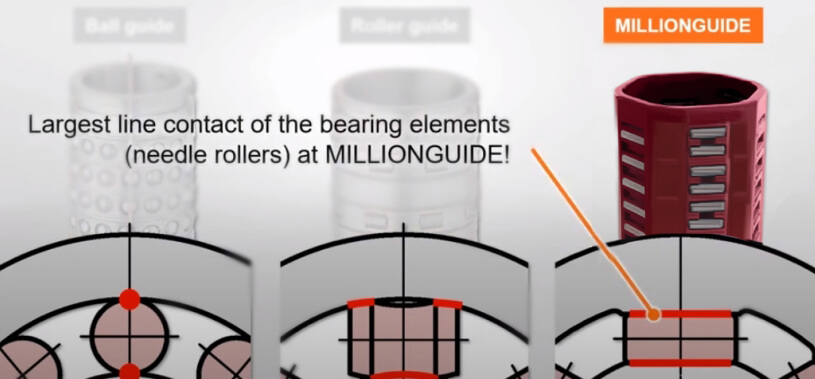

Circular Ball Type vs Roller Type

In the current market, guide posts for stamping dies predominantly use the Circular Ball Type. However, with the rapid development of electric vehicles, the demand for higher precision and lower friction in die stamping processes has increased. This has led to the widespread adoption of Roller Type guide posts.

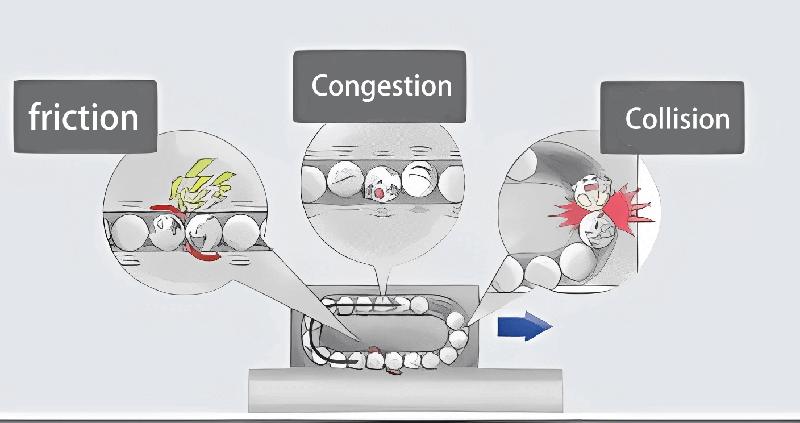

Characteristics of Circular Ball Type

Traditional Circular Ball Type guide posts have the following characteristics:

- Contact and Collision: Balls contact and collide with each other, generating friction, which leads to wear, dust generation, and heat.

- Cyclic Preloading: During operation, the balls undergo repeated preloading and unloading, causing vibrations.

Advantages of Roller Type

In contrast, Roller Type guide posts offer significant advantages:

- Zero Contact Design: Rollers do not contact each other, eliminating friction, wear, and dust generation.

- Low Preload and Smooth Rolling: The non-cyclic design with low preload results in minimal impact and vibration, enabling smoother rolling.

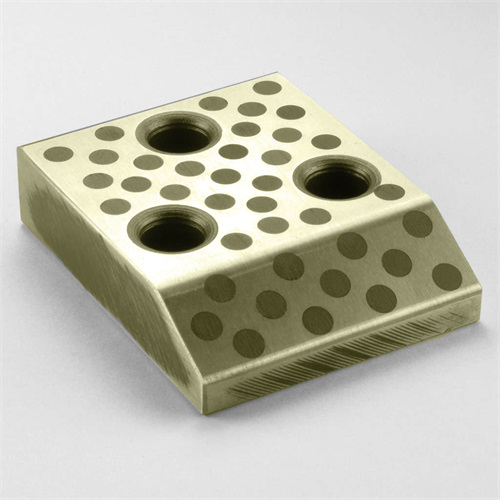

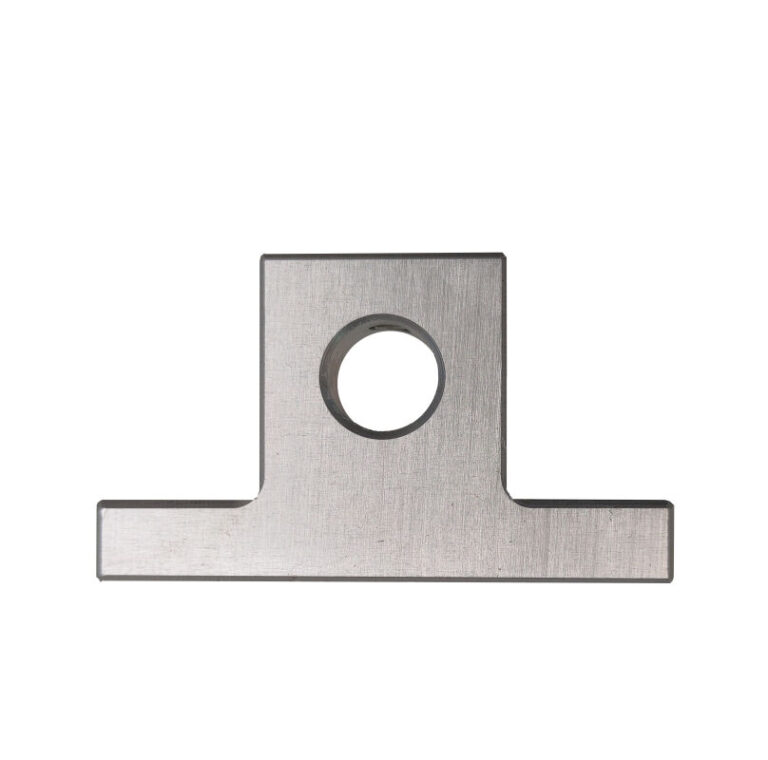

- Durable Structure: Comprising Needle Roller Cage (plastic), Guide Bush (hardened steel), Guide Unit (hardened steel), and Needle Roller (hardened steel), the structure is robust and durable.

GUNRI’s Roller Guide Post Sets are widely used in high-precision fields, especially in electric vehicle battery and semiconductor chip production:

- In the battery industry, the occurrence of burrs on parts directly affects battery safety, a challenge faced by various new energy enterprises. Smooth parts often require high-precision control of stamped components.

- In the chip industry, they are mainly used in lifting platform equipment to accurately raise chip materials to fixed heights.

GUNRI’s Roller Guide Post Sets effectively reduce friction, improve precision, and ensure high-quality production of critical components. Customers have highly praised their significant advantages in enhancing production efficiency and product quality.

GUNRI specializes in manufacturing various precision mold components and offers custom processing services.

Choosing GUNRI for high-precision mold components is a wise decision. Our Roller Guide Post Sets have been validated in multiple industries and can be customized according to your specific needs.

Contact us now to learn more about our custom services and product information.