Die Set Guide Posts Manufacturers: A Comprehensive Guide

In the precision-driven world of die set manufacturing, guide posts play an essential role in ensuring accurate alignment and smooth operation of dies. As manufacturers of die set guide posts, we understand the significance of delivering products that enhance productivity, reduce maintenance costs, and provide long-lasting reliability. This comprehensive guide delves into every aspect of die set guide posts, exploring their uses, materials, manufacturing processes, and the importance of partnering with trusted manufacturers.

Table of contents

- The Critical Role of Die Set Guide Posts

- Materials Used in Die Set Guide Posts

- Manufacturing Processes for Guide Posts

- The Importance of Tolerance in Guide Post Manufacturing

- Types of Guide Posts for Die Sets

- Customization of Guide Posts

- Choosing the Right Die Set Guide Posts Manufacturer

- Final Thoughts: Enhancing Your Tooling System with Quality Guide Posts

The Critical Role of Die Set Guide Posts

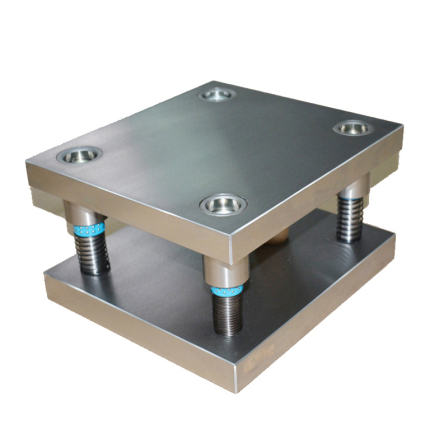

Guide posts are integral to the function of a die set. Positioned within the die assembly, they ensure the proper alignment of the upper and lower die halves during operation. By maintaining this alignment, guide posts prevent damage to both the die and the material being processed, ensuring that each stroke results in the precise formation of parts. They are indispensable components in applications where precision and durability are paramount.

In stamping, forming, and other tooling operations, the performance of the die set hinges on the quality of the guide posts. Poor-quality guide posts can lead to misalignment, wear, and, ultimately, production inefficiencies. That’s why choosing the right manufacturer is crucial for businesses seeking to optimize their tooling systems.

Materials Used in Die Set Guide Posts

The choice of material for guide posts has a significant impact on their performance and longevity. As experienced manufacturers, we work with a variety of materials to meet the diverse needs of our clients. Common materials include:

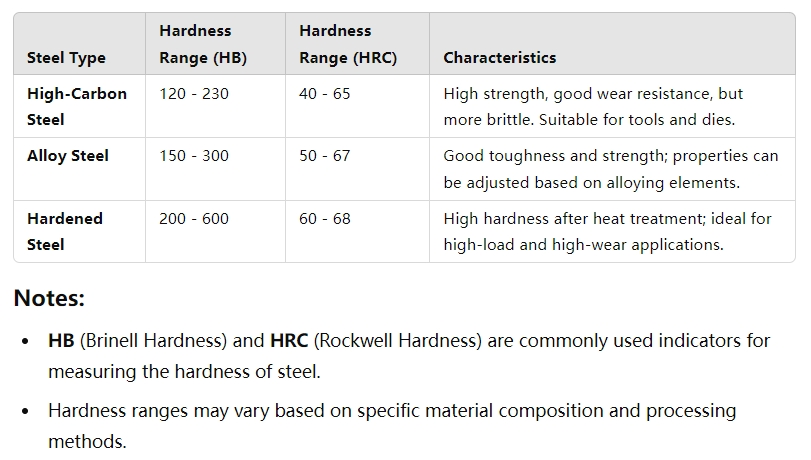

- High-Carbon Steel: Known for its strength and durability, high-carbon steel is a popular choice for guide posts used in high-impact environments. It offers excellent wear resistance, which is essential for prolonging the life of both the guide posts and the die set.

- Alloy Steel: This material combines various metals to enhance strength, toughness, and resistance to deformation. Alloy steel guide posts are particularly well-suited for applications requiring high strength and durability under extreme pressure.

- Hardened Steel: The heat-treatment process used to harden steel significantly improves its wear resistance, making hardened steel guide posts ideal for high-speed, high-precision operations.

By selecting the right material based on the specific demands of the production process, guide post manufacturers can ensure optimal performance and extended service life.

Manufacturing Processes for Guide Posts

The production of die set guide posts is a meticulous process that demands precision at every stage. We adhere to stringent quality standards to ensure that our guide posts deliver consistent results under the most demanding conditions. Here are some of the key manufacturing processes we utilize:

- CNC Machining: Our use of advanced CNC (Computer Numerical Control) machining ensures that each guide post is produced with unparalleled precision. This technology allows us to maintain tight tolerances, resulting in products that meet exacting specifications.

- Heat Treatment: We employ heat treatment to enhance the mechanical properties of our guide posts, improving their hardness and wear resistance. This process is critical for ensuring that the posts can withstand the rigors of high-volume production environments.

- Grinding and Polishing: The surface finish of a guide post is critical to its performance. By utilizing grinding and polishing techniques, we achieve a smooth, uniform finish that minimizes friction and wear during die operation.

- Quality Control and Testing: We employ rigorous quality control measures at every stage of production, including dimensional inspections, material testing, and performance evaluations. These steps ensure that every guide post we produce meets the highest standards of precision and durability.

The Importance of Tolerance in Guide Post Manufacturing

One of the most critical aspects of guide post manufacturing is achieving the correct tolerances. A guide post must fit perfectly within its bushing and allow for smooth, friction-free movement during the die operation. Too much play can result in misalignment and damage, while a post that is too tight can cause excessive wear and require frequent replacement.

Our manufacturing processes ensure that tolerances are kept within a precise range, allowing for the optimal balance of movement and stability. Whether the application requires a press-fit or slip-fit, we can customize our guide posts to meet the exact specifications of each project.

Types of Guide Posts for Die Sets

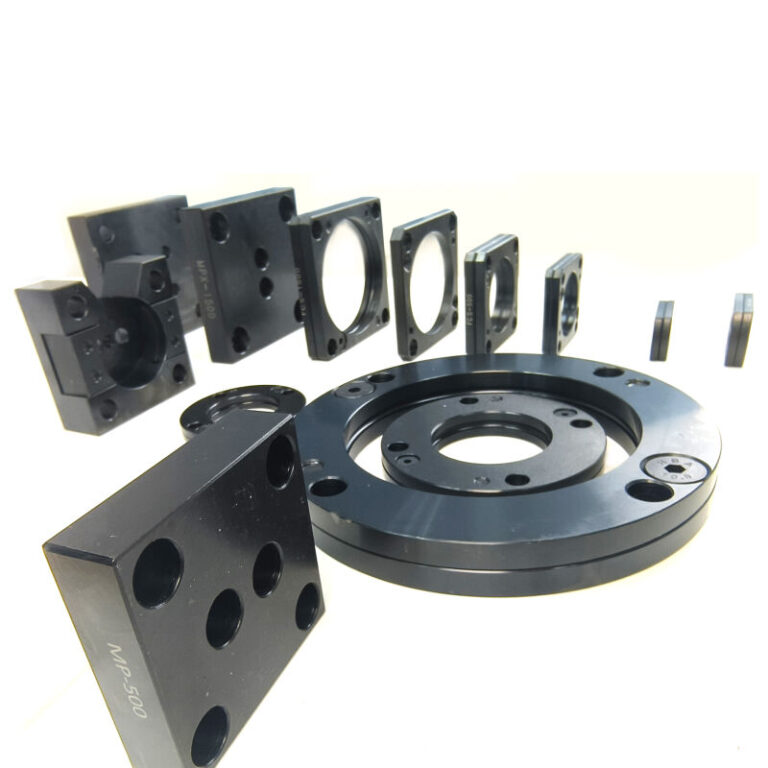

There are several types of guide posts used in die sets, each suited to different applications. As guide post manufacturers, we offer a range of products to meet the diverse needs of our clients:

- Plain Guide Posts: These posts offer a simple, cost-effective solution for applications where high precision is not required. They are commonly used in less demanding operations, such as light stamping or forming.

- Precision Guide Posts: Designed for applications where extreme accuracy is needed, precision guide posts are manufactured to exacting tolerances. They are typically used in high-speed or high-volume operations where even minor misalignments can result in costly errors.

- Ball Bearing Guide Posts: These posts incorporate ball bearings to reduce friction and wear. They are ideal for high-load applications where frequent movement is required, such as in automotive stamping or other heavy-duty industries.

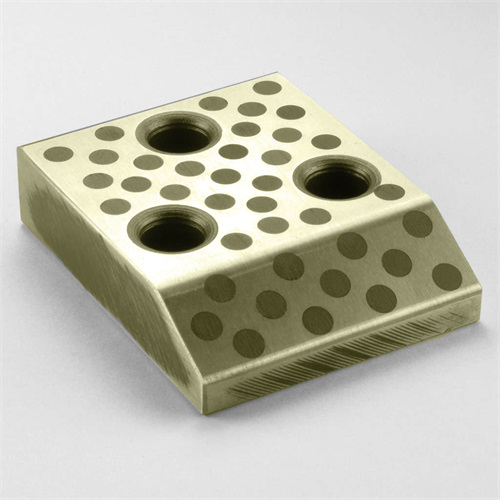

- Self-Lubricating Guide Posts: To reduce the need for maintenance, we offer self-lubricating guide posts that incorporate materials like bronze or graphite to provide continuous lubrication during operation. These posts are perfect for environments where consistent lubrication is difficult to maintain.

Customization of Guide Posts

We recognize that every project has unique requirements, which is why we offer custom guide post manufacturing to meet the specific needs of our clients. Whether it’s adjusting dimensions, tolerances, or materials, our engineering team works closely with customers to design and produce guide posts that fit seamlessly into their die sets.

Customization options include:

- Length and Diameter Adjustments: We can tailor the dimensions of the guide posts to accommodate specific die designs, ensuring the perfect fit.

- Material Selection: Based on the working environment and application, we can recommend and use specialized materials to enhance the performance of the guide posts.

- Surface Coatings: For environments where corrosion or high wear is a concern, we offer a variety of surface coatings, such as chrome or nickel plating, to extend the lifespan of the guide posts.

Choosing the Right Die Set Guide Posts Manufacturer

When selecting a guide post manufacturer, it’s essential to consider factors such as industry experience, production capabilities, and a proven track record of delivering high-quality products. As a leading manufacturer of die set guide posts, we pride ourselves on our ability to deliver superior products backed by exceptional customer service.

Our commitment to innovation and quality ensures that our guide posts not only meet but exceed the demands of modern tooling operations. Whether you require standard or custom guide posts, we have the expertise and resources to meet your needs.

Final Thoughts: Enhancing Your Tooling System with Quality Guide Posts

At the heart of every successful die set is a high-quality guide post. By investing in the best materials, precise manufacturing processes, and a trusted supplier, businesses can achieve greater precision, reduce downtime, and extend the life of their tooling systems. Our extensive experience in the field of guide post manufacturing allows us to deliver solutions that are both cost-effective and highly reliable.

At GUNRI, we are dedicated to supporting your business with top-tier guide posts that are tailored to your specific needs. If you’re looking for the perfect partner to enhance your production process, contact GUNRI today for a consultation, and let our team help you take your operations to the next level.