Differentiating between Sprue Bushings and Ejector Pins in Plastic Mold Accessories

Sprue bushings and ejector pins are both types of components found in plastic mold accessories. Ejector pins are a common type of pin within the sprue bushing and pin assembly, and they serve as metal rods for ejecting molded products. With the presence of both sprue bushings and ejector pins, molds can continuously push out products in high-speed operations, thereby boosting production efficiency.

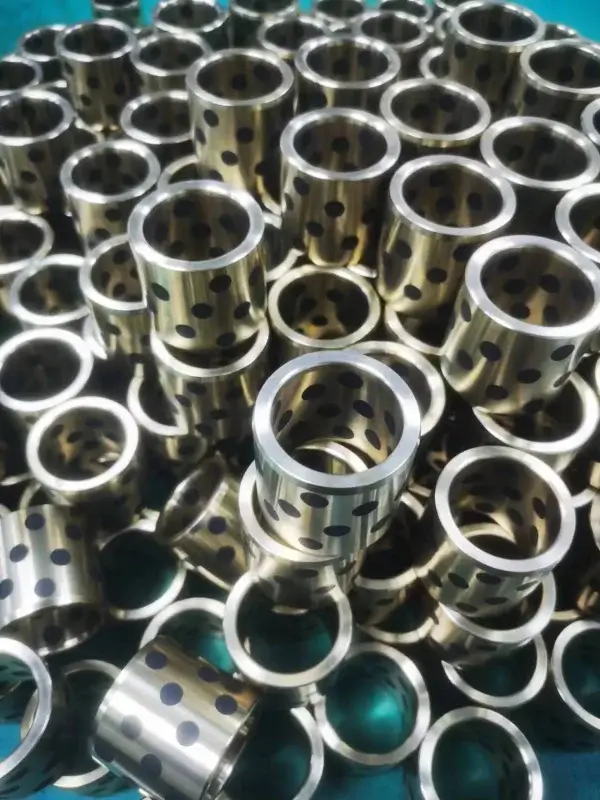

Standard Ejector Pins:

First and foremost, the distinction between sprue bushings and ejector pins lies in their roles as components of two entirely different mold setups. From an external perspective, sprue bushings are hollow, while standard ejector pins are solid, elongated, and pointed at one end. Sprue bushings tend to be made of relatively harder materials. Moreover, both ejector pins and sprue bushings are composed of two parts: the bushing itself and the ejector pin. The inner pin in a sprue bushing is capable of upward movement. When this inner pin is fixed to the mold’s base plate, the sprue bushing is positioned above the ejector pin plate. Upon ejection, the sprue bushing moves along with the ejector pin.

In terms of nomenclature, sprue bushings and ejector pins are distinct. They are often used in combination, forming what’s known as a sprue bushing and pin assembly. The sprue bushing within this assembly can also be referred to as a top bushing or a hollow ejector pin. These can further be categorized into straight sprue bushings and stepped sprue bushings, among others. On the other hand, ejector pins are commonly known as support pins or insert pins.

Ejector Pins:

To sum it up, the primary differences between sprue bushings and ejector pins encompass the points mentioned above. For those seeking a deeper understanding of these components, there are specialized resources available online for further research. Both sprue bushings and ejector pins are widely used nowadays, and there exists a variety of types in the market. Therefore, it’s essential to exercise caution and choose quality sprue bushings and ejector pins from reputable sources when making your selection.”

【Gunri’s Note】: If you’re looking to enhance mold precision while minimizing wear and tear, consider exploring Gunri’s range of high-precision mold spare parts. Our solutions can make a significant difference in your manufacturing process.