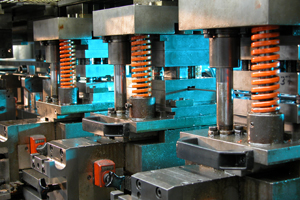

Ensuring Mold Longevity: Preventing Crashes in Production

In the intricate world of manufacturing, the durability of molds is a critical factor influencing both efficiency and cost-effectiveness. Unfortunately, the production floor is not immune to mishaps, often referred to as “crashes,” which can significantly impact mold longevity. Let’s delve into some common scenarios and explore strategies to prevent these crashes and extend the lifespan of molds.

Cam Misalignment: A Leading Cause of Crashes

Among the most prevalent crashes, misalignment of a cam stands out as a recurring issue. This misalignment is often triggered by activities such as parting line cleaning or part removal. Sometimes, the cam retention mechanism proves inadequate, causing the cam to shift from its intended position. This seemingly small misalignment can lead to disastrous consequences, akin to a twig snapping. If the angle pin doesn’t align correctly with the cam’s hole and only grazes the top, it might require a simple pin replacement. However, when the angle pin strikes a cavity impression, the repercussions are far more severe. Such an impact can bring production to a halt, resulting in significant repair costs.

The Perils of Insufficient Safety Measures

Another crash scenario involves the improper handling of molds, often due to using only one eyebolt without a safety strap. In these cases, a mold half might make contact with the ground before any warning shouts can be raised. These seemingly minor incidents can have far-reaching consequences, potentially damaging the mold and drastically shortening its lifespan.

Preventive Measures for Prolonged Mold Life

Awareness and proactive measures are key to preventing crashes and maintaining mold longevity. Implementing sturdy retention devices for cams, ensuring precise alignment of components, and adhering to safe handling practices can collectively contribute to avoiding avoidable accidents. Properly securing molds during transport and using appropriate lifting equipment can prevent mishaps caused by mishandling.

The Bottom Line: Protecting Your Investment

Mold durability is an essential aspect of efficient manufacturing operations. Recognizing crash-prone scenarios and taking preventive action is essential to protect your molds, minimize downtime, and reduce repair costs. By fostering a culture of vigilance and investing in the right practices and equipment, manufacturers can ensure that their molds not only survive but thrive in the demanding world of production. After all, safeguarding your molds is safeguarding your production success.

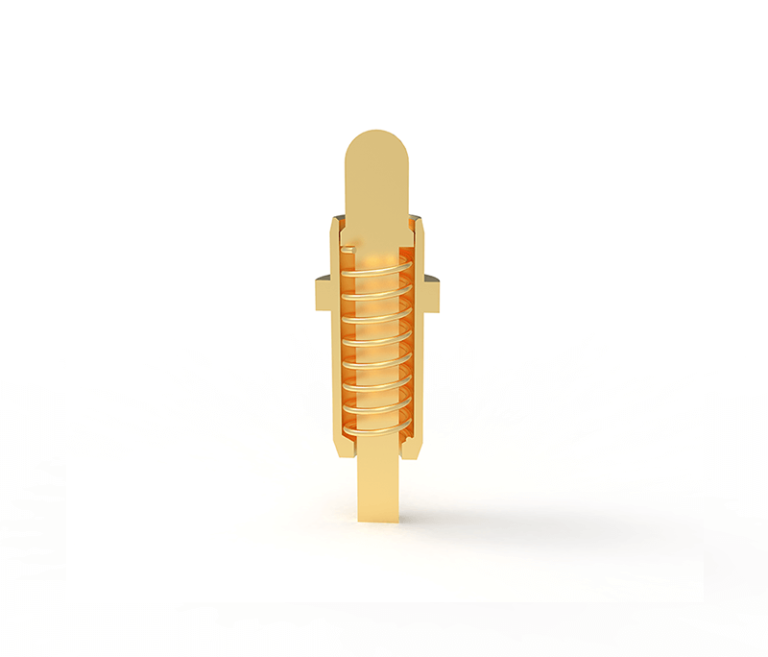

Learn More About High-Precision Mold Components

At Gunri, we understand the importance of precision in every aspect of manufacturing. Our high-precision mold components are designed to reduce wear and tear on molds, ensuring extended lifespans and optimal performance. Contact us today to discover how our advanced mold solutions can enhance your production processes and protect your valuable investments.