Everything About Metal Stamping Parts and Die Components

What is the stamping process in sheet metal and why are die components essential?

Sheet metal stamping uses a press and die set to cut or form flat metal sheets into parts.

Die components such as punches, guide systems, and nitrogen gas springs ensure that each cycle is precise and repeatable.

Without these parts, mass production would not be possible.

What metal stamping techniques require precision mold components?

Stamping operations include blanking, bending, forming, and deep drawing.

Each technique relies on specific die components—for example, deep drawing requires strong punches, while bending needs precise guiding systems.

What are the main tools and die parts used for metal stamping?

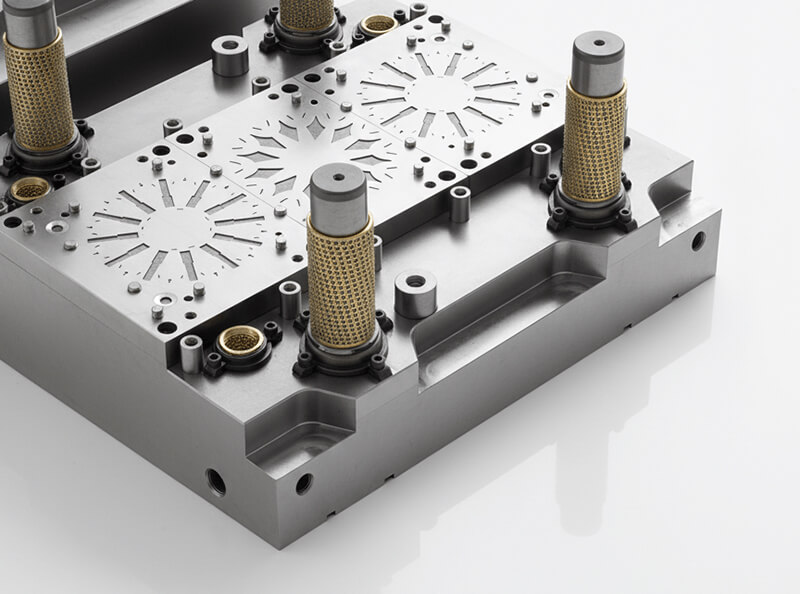

The stamping press provides force, while the die controls shaping. Inside the die, critical parts include dowel pins, punches, bushings, stripper systems, and nitrogen gas springs.

These components ensure accuracy and tool life.

What are the applications of stamping die components in manufacturing?

Die components are used in automotive body parts, EV motor stator laminations, home appliances, electronics, and industrial automation.

GUNRI supplies the precision mold components that support these industries worldwide.

How does a stamping machine work together with dies and tooling parts?

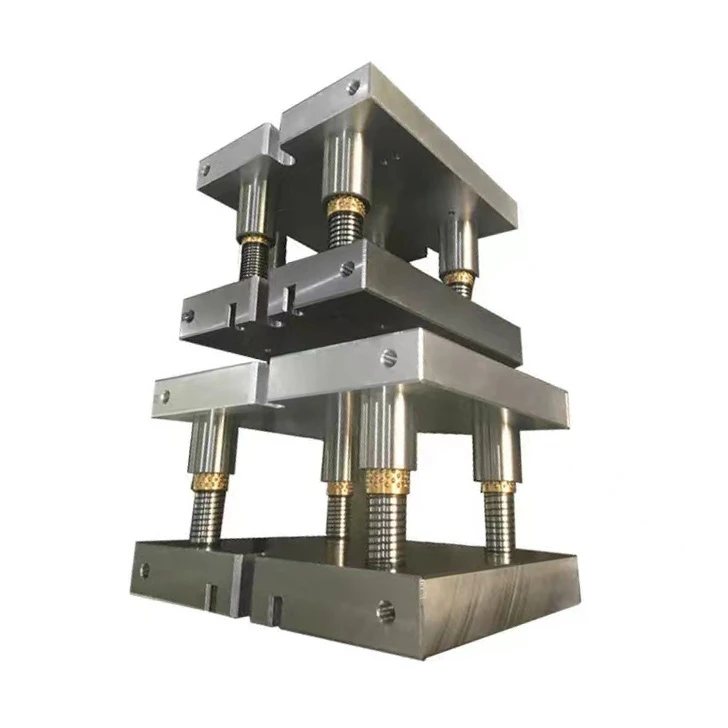

The press applies pressure, the die shapes the material, and die components manage movement, alignment, and stripping.

Each part—from guide pillars to springs—ensures stability and accuracy.

What is a metal stamping die and how are its components made?

A stamping die is an assembly of multiple components, including punches, bushings, and guide systems.

These parts are produced with CNC machining, grinding, and heat treatment before being assembled into a complete tool.

What types of dies and accessories are used in stamping?

Single-operation dies, compound dies, and progressive dies are common.

Accessories such as nitrogen gas springs and guide pillars enhance performance and durability.

What is automated stamping and what mold components support it?

Automated stamping uses progressive dies with continuous material feeding.

It requires reliable die components such as high-precision guide sets and long-life nitrogen gas springs to ensure uninterrupted production.

How to differentiate between metal stamping and mold fabrication?

Stamping produces end-use parts, while mold fabrication produces the tools that enable stamping.

GUNRI focuses on mold and die components, not finished stamped parts.

What metals can be stamped and what die parts are needed?

Materials include carbon steel, stainless steel, aluminum, copper, and silicon steel.

Different die components are required—for instance, hard punches for stainless steel and wear-resistant bushings for silicon steel.

How to minimize costs in stamping by choosing the right die components?

Using durable punches, standardized guide systems, and reliable stripper bushings reduces downtime and scrap.

Correct die component selection saves costs over the long term.

What is heavy stamping and how do mold parts withstand it?

Heavy stamping processes thick or high-strength sheets with large presses.

This requires reinforced punches, heavy-duty nitrogen gas springs, and high-strength guide pillars to withstand stress.

What tolerances are possible when using precision die components?

With high-quality tooling, tolerances as tight as ±0.01mm to ±0.05mm are achievable.

Precision depends on accurate punches, bushings, and guiding systems.

How to perform custom stamping with non-standard mold components?

Custom stamping often requires non-standard components.

GUNRI manufactures custom dowel pins, special punches, or oversized guide pillars based on drawings or samples.

What stamping presses and die parts are used for high-volume production?

High-speed presses with progressive dies are used in mass production.

These rely on durable die components such as precision punches, stripper bushings, and nitrogen gas springs.

How to design stamping parts with proper die components?

Good design considers manufacturability, tool life, and material properties.

Selecting the right die components early ensures stable production and lower costs.

What is precision stamping and how do tooling parts ensure accuracy?

Precision stamping achieves micron-level accuracy, often for electronics or automotive parts. Accurate guide systems, finely ground punches, and preloaded springs are critical.

What is hot metal stamping and what dies are required?

Hot stamping heats sheet metal before forming and rapid cooling.

Dies require heat-resistant steels, surface coatings, and cooling systems. Supporting parts must handle high heat and impact.

Can GUNRI make stamping die components based on my sample?

Yes. GUNRI can measure, reverse-engineer, and manufacture die components such as guide pillars, nitrogen gas springs, or punches directly from your sample.

We specialize in tooling parts, not end-use stamped products.

What is GUNRI’s MOQ when ordering stamping die components?

For standard parts, MOQs can be a few hundred pieces. For custom parts, the MOQ depends on design and machining requirements.

GUNRI supports both trial orders and mass production.

Need precision die components for your stamping production?

Contact GUNRI today. We manufacture high-quality dowel pins, guide pillars, nitrogen gas springs, stripper bushings, and custom tooling parts for stamping dies worldwide.