Exploring Leader Pins: A Vital Component in the World of Molds and Dies

In the intricate world of molds and dies, even the tiniest components can make a world of difference. Among these essential components, Leader Pins play a pivotal role. These unassuming, yet indispensable, parts are instrumental in ensuring precision and quality in the manufacturing process. In this comprehensive 2000-word article, we will delve deep into the world of Leader Pins, exploring their significance, various types, applications, and how they contribute to the success of the mold and die industry.

Table of contents

1. Understanding the Importance of Leader Pins

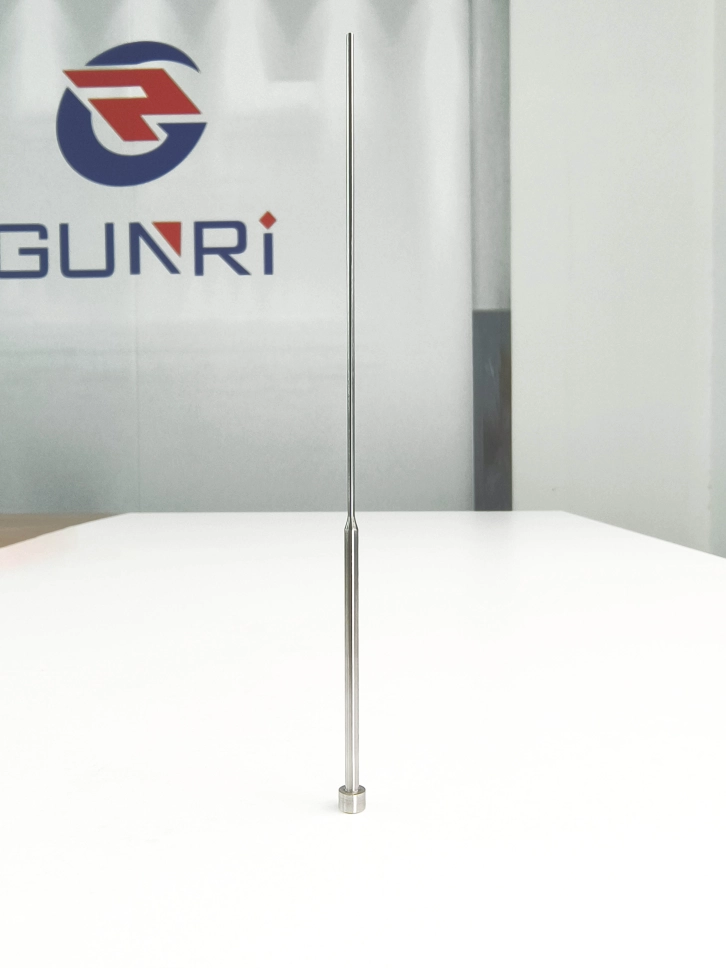

Leader Pins are unassuming components, often cylindrical in shape, but they are the unsung heroes in mold and die operations. They are primarily used to guide, align, and support the movement of mold components, ensuring that the mold functions accurately and consistently. Without Leader Pins, molds and dies may suffer from misalignment, leading to defects in the products being manufactured.

2. Types of Leader Pins

Leader Pins come in a variety of types, each designed for specific applications:

a. Standard Leader Pins

These are the most common type of Leader Pins, used in a wide range of mold and die applications. They are characterized by their simple cylindrical design and are ideal for general-purpose use.

b. Ejector Pins

Ejector Pins, a subset of Leader Pins, are specifically designed to aid in the ejection of finished parts from molds. They are an essential component in injection molding processes.

c. Shoulder Leader Pins

Shoulder Leader Pins feature a distinct shoulder portion, designed to provide additional support and guidance within the mold or die. They are particularly useful in applications where heavy loads or precision alignment is required.

d. Dowel Pins

Dowel Pins are precision Leader Pins used for accurate alignment in tight-tolerance applications. They are essential in ensuring the precise fit of mold halves and maintaining the alignment of critical features in the finished product.

3. Applications of Leader Pins

Leader Pins find applications across a wide spectrum of industries and manufacturing processes:

a. Injection Molding

In injection molding, Leader Pins are critical for the alignment and assembly of mold components, ensuring the production of defect-free plastic parts.

b. Stamping and Die-Cutting

In stamping and die-cutting operations, Leader Pins guide the movement of dies, enabling precise cuts and punches in materials ranging from metal to paper.

c. Metal Casting

In metal casting, Leader Pins play a crucial role in the accurate formation of molds for molten metal, enabling the production of complex metal parts.

d. Electronics Manufacturing

Leader Pins are used in the fabrication of electronic components and PCBs, ensuring the precise alignment and assembly of intricate electronic parts.

4. The Significance of Precision in Leader Pins

The quality and precision of Leader Pins are of utmost importance. Even slight variations in the diameter, length, or alignment of Leader Pins can lead to significant defects in the final products. Manufacturers like Gunri Mold understand this critical aspect and ensure that their Leader Pins meet the strictest quality standards.

5. Gunri Mold: Your Trusted Source for Mold and Die Components

In the competitive world of mold and die manufacturing, Gunri Mold has established itself as a reliable and cost-effective solution. Specializing in the production of mold and stamping components, Gunri Mold has earned a reputation for its swift deliveries, affordable pricing, and commitment to quality.

With an authentic workshop where high-quality components are manufactured, Gunri Mold has set a standard for transparency and quality assurance in the industry.

In conclusion, Leader Pins are the unsung heroes in the world of molds and dies. These unassuming components play a critical role in ensuring precision, alignment, and quality in a wide range of manufacturing processes. Gunri Mold, with its commitment to quality and affordability, stands as a trusted source for mold and die components, ensuring that your operations run smoothly and efficiently.

For manufacturers and engineers seeking dependable solutions for mold and die components, Gunri Mold’s dedication to quality and customer satisfaction makes it a wise choice. Make your mold and die operations more efficient and cost-effective with Gunri Mold’s precision components. Choose Gunri Mold for reliable, affordable, and high-quality components, and take your manufacturing to the next level.