Exploring the Benefits of Plastic Ball Cage Retainers for Die Sets

In the world of die sets and stamping components, precision, durability, and cost-effectiveness are paramount. Manufacturers and engineers are constantly seeking solutions that not only enhance the performance of their dies but also maintain affordability. One such solution that has gained significant attention is the use of Plastic Ball Cage Retainers. In this article, we will delve into the advantages of using plastic ball cage retainers for die sets, with a focus on the offerings of Gunri Mold, a trusted name in the industry.

Table of contents

The Role of Plastic Ball Cage Retainers

Before we explore the benefits, let’s understand the role of plastic ball cage retainers in die sets. These components play a crucial role in guiding and retaining balls or rollers within the die set, ensuring smooth and precise movement. Here’s why they matter:

- Reduced Friction: Plastic ball cage retainers offer a low-friction solution, allowing for smooth movement even under heavy loads.

- Precision: They contribute to the precision of the die set, ensuring accurate alignment and operation.

- Cost-Effective: Compared to traditional materials, plastic ball cage retainers are known for their cost-effectiveness.

The Advantages of Plastic Ball Cage Retainers

Now, let’s dive into the specific advantages of using plastic ball cage retainers in die sets:

1. Low Friction, High Efficiency

One of the standout features of plastic ball cage retainers is their remarkably low friction coefficient. This property minimizes wear and tear within the die set, leading to increased efficiency and longer tool life. As a result, you can expect reduced maintenance and replacement costs.

2. Versatility in Applications

Plastic ball cage retainers are incredibly versatile and suitable for various die set applications, including cold punching molds, precision machine tools, and more. Their adaptability across different industries makes them a valuable choice for manufacturers with diverse needs.

3. Affordability Without Compromise

In a competitive market, cost considerations are paramount. Gunri Mold understands this need and provides plastic ball cage retainers that combine affordability with quality. With Gunri Mold, you can access cost-effective solutions without compromising on performance or durability.

4. Swift Delivery and Reliable Supply

Gunri Mold is known for its commitment to customer satisfaction. With a dedication to timely deliveries, you can count on them to meet your production schedules without delays. Their responsive customer service ensures a smooth and hassle-free experience.

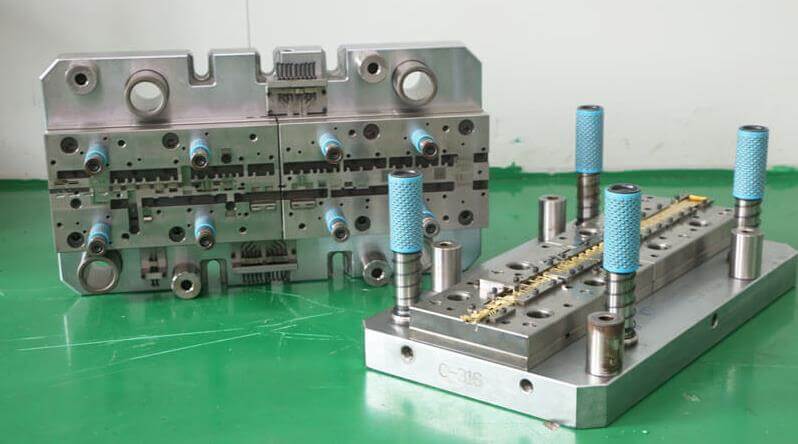

5. A Glimpse into Gunri Mold’s Real Workshop

At Gunri Mold, transparency is a core value. They take pride in their real workshop, where the production of high-quality die set components takes place. This commitment to maintaining a genuine and efficient workspace speaks volumes about their dedication to quality.

Conclusion

In conclusion, plastic ball cage retainers are proving to be a game-changer in the world of die sets and stamping components. With their low friction, versatility, cost-effectiveness, and the assurance of Gunri Mold’s timely deliveries and real workshop, you can trust in the enhanced performance and affordability they bring to your operations.

For manufacturers and engineers looking to optimize their die sets, plastic ball cage retainers are indeed a promising solution. Contact Gunri Mold today to explore how these components can benefit your specific die set requirements. Whether it’s precision, durability, or cost-effectiveness you seek, plastic ball cage retainers deliver on all fronts.

Make the smart choice for your die sets. Choose Gunri Mold for reliable, affordable, and high-quality plastic ball cage retainers. Your journey to enhanced die set performance begins here.