Exploring the Procurement of Mold Spare Parts in China: What’s the True Cost-Effectiveness?

The Crucial Decision in Mold Spare Parts Procurement

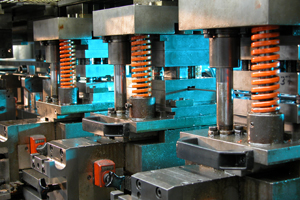

Mold spare parts play an indispensable role across various industries. From automotive manufacturing, where precision molds shape car body panels, to the consumer goods sector that churns out plastic wares with the help of injection molds, the quality and availability of these parts can make or break production schedules. However, one of the most perplexing questions for international buyers like us is where to source these parts. China has emerged as a prominent candidate, but the big question remains: Is it truly the cheapest option?

An Analysis of the Cost Advantages of Chinese Mold Spare Parts

1. Raw Material Supply and Cost Edge

China stands as a behemoth in raw material production. When it comes to mold steel, for instance, it boasts vast reserves of high-quality ore. The nation’s mining and smelting industries have achieved remarkable feats in terms of production volume. Year after year, China tops the global charts in steel output, ensuring an abundant supply for the mold-making sector. Quality control measures are also stringent, with modern laboratories and strict national standards. All these factors combine to offer cost savings; with local sourcing of materials, Chinese mold part manufacturers can cut down on transportation and import duties, passing on some of these savings to customers.

2. The Price Benefits of Large-Scale Production

China has witnessed the rise of numerous mold spare parts industrial clusters, especially in regions like the Pearl River Delta and Yangtze River Delta. These clusters are a hive of activity, with hundreds of specialized factories operating in close proximity. Take a small town in the Pearl River Delta, for example. Here, a single order for a common mold component can be split among multiple factories, each focusing on a specific production stage. This division of labor, made possible by the cluster setup, not only speeds up production but also significantly reduces costs. As the scale of production ramps up, manufacturers can negotiate better deals with suppliers, invest in more efficient machinery, and ultimately offer more competitive prices.

The Balance Between Quality and Price

1. Stringent Quality Control Systems

Chinese mold part manufacturers have been upping their game when it comes to quality. A vast number of them now hold international certifications such as ISO 9001. Inside their factories, advanced inspection equipment like coordinate measuring machines (CMMs) are the norm. These machines can detect the tiniest of flaws in a part, ensuring that only products meeting the strictest tolerances leave the factory floor. Many Chinese companies also participate in global quality benchmarking initiatives, constantly striving to improve their processes.

2. Product Distribution in High-End and Mid-Low-End Markets

China’s mold spare parts industry has a diverse product portfolio. In the high-end market, Chinese manufacturers are investing heavily in research and development, collaborating with international tech giants and universities. They are now capable of producing highly complex, precision-engineered parts that can rival European and American counterparts. Meanwhile, in the mid – low-end market, they leverage their cost advantages to offer reliable, budget-friendly options. This two-pronged approach means that, regardless of your budget or technical requirements, there are Chinese mold spare parts that can fit the bill.

Potential Challenges in Procurement and Their Solutions

1. Communication and Cultural Differences

When doing business across borders with Chinese suppliers, communication and cultural barriers often surface. Language differences can lead to misunderstandings, and cultural norms play a significant role in business negotiations. For instance, the concept of “face” in Chinese culture might affect how suppliers respond to criticism. To overcome these, it’s essential to establish clear communication channels. Using professional interpreters, writing detailed contracts, and investing time in cultural exchange can bridge the gap.

2. Logistics and Supply Chain Risks

International logistics from China can be a headache. Long shipping distances mean higher risks of delays, damage, and customs issues. However, China has been rapidly upgrading its logistics infrastructure. Major ports are now some of the most efficient in the world, with advanced container handling systems. To mitigate risks, buyers can opt for reliable freight forwarders, purchase insurance, and work closely with suppliers to ensure proper packaging and timely shipping.

Insights and Recommendations from Industry Insiders

Industry buyers and experts have a wealth of knowledge when it comes to sourcing from China. Some seasoned procurement officers recommend starting small, building trust with a few reliable suppliers before scaling up orders. Others emphasize the importance of on-site factory visits, which provide a firsthand look at production capabilities. Experts also suggest keeping an eye on China’s evolving trade policies, as they can impact pricing and delivery times in the long run.

Conclusion: Is China a Sensible Choice for Mold Spare Parts Procurement?

In summary, China offers a compelling mix of cost advantages, from raw materials to large-scale production, along with a steadily improving quality profile. While there are challenges in communication, culture, and logistics, with the right strategies, they can be effectively managed. For international buyers, it’s crucial to weigh these factors carefully, considering your specific needs, budget, and risk tolerance. After all, in the world of mold spare parts procurement, the optimal choice is often a nuanced balance of multiple elements. We’d love to hear your thoughts and experiences in the comments section below.