Extrusion Die Punch: The Complete Guide for Precision Metal Forming

In modern metal fabrication, manufacturers are pushing for higher speed, tighter tolerances, and longer tool life. Among all the tooling components that determine production performance, the extrusion die punch plays one of the most critical roles.

Whether you’re producing automotive brackets, construction hardware, stainless steel channels, or custom profile parts, a well-designed extrusion die punch can dramatically improve forming quality and reduce tooling cost.

In this article, we’ll walk through everything you need to know—including working principles, design considerations, materials, coating options, and how to choose the right punch supplier.

What Is an Extrusion Die Punch?

An extrusion die punch is a precision tool used in metal stamping to force the workpiece through a shaped die opening, forming a hole or profile that is longer than the material thickness.

This means the punch does more than simply cut—it actually extrudes the metal, creating a clean, strengthened, and elongated shape.

Compared with traditional punching, extrusion punching offers:

- Stronger hole walls

- Improved dimensional accuracy

- Better thread-forming readiness

- Reduced burrs and edge cracks

This process is widely used in sheet metal fabrication, automotive components, electrical enclosures, aluminum profiles, and custom hardware.

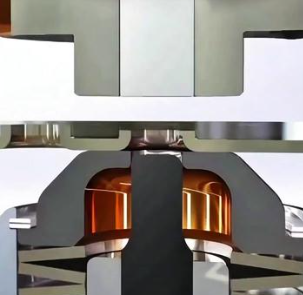

How an Extrusion Die Punch Works

The extrusion punch enters the sheet metal and forces the material through the die opening. During this stage:

- Metal begins to flow plastically.

- Material elongates into the die cavity.

- A strengthened, tube-like wall is formed.

- The punch retracts, leaving a clean extruded feature.

This controlled material flow is why extrusion punches require high hardness and excellent toughness—they endure far more stress than normal punches.

Key Design Factors for an Extrusion Die Punch

1. Punch Material

Choosing the right steel directly affects performance and lifetime.

Common materials include:

- M2 / SKH51 (high wear resistance)

- DC53 / SKD11 (balanced toughness & hardness)

- Powder metallurgy steels (PMM4, ASP23, ASP30) (excellent for high-speed forming)

- Carbide punches (for extreme wear environments)

2. Coating Options

A surface coating significantly improves punch life and reduces friction.

Popular coatings:

- TiN – general use

- TiCN – higher hardness for abrasive materials

- AlTiN – heat-resistant for high-speed stamping

- DLC – low friction for stainless steel & aluminum

3. Extrusion Length

Longer extrusions require:

- Stronger punch bodies

- Better lubrication

- Higher-grade die steels

Typical extrusion lengths:

1.5× → 3× material thickness

4. Punch Geometry

The punch tip radius, angle, and body tolerance greatly influence:

- Surface finish

- Force required

- Material flow

- Hole strength

Proper geometry reduces cracking and prevents punch breakage.

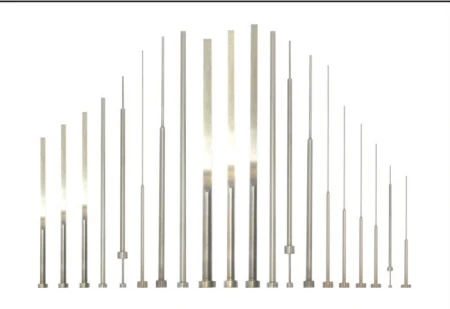

Types of Extrusion Die Punches

Depending on the application, extrusion punches come in several forms:

- Standard forward extrusion die punch

- Reverse extrusion punch

- Hex or special-shape extrusion punches

- Step extrusion die tools

- Progressive die extrusion punches

- Thread-forming extrusion punches

Each type is engineered for a specific material flow and production requirement.

Advantages of Extrusion Die Punching

✔ Stronger Hole Structure

Material is not removed but reshaped—improving strength around the opening.

✔ Excellent Dimensional Accuracy

Perfect for precision component manufacturing.

✔ Burr-Free or Low-Burr Operation

Reduces secondary finishing cost.

✔ Supports Thread Forming (Tapping/Thread Rolling)

Ideal for applications where internal threads are required.

✔ Extended Tool Life

Less shock load compared to traditional punching.

Applications of Extrusion Die Punches

Extrusion punches are widely used in:

- Automotive brackets & chassis components

- Electrical panel housings

- Construction and HVAC hardware

- Aluminum extrusion parts

- Stainless steel enclosures

- Heavy-duty mounting systems

- Solar mounting hardware

- Custom sheet metal fabrication

If the part requires a structurally strong or elongated hole, extrusion is the ideal process.

How to Choose the Right Extrusion Die Punch Supplier

When sourcing extrusion punches, consider:

1. Ability to Customize

Every extrusion application is unique—your supplier must support custom sizes, shapes, and coatings.

2. Material Certification

High-quality steel means longer tool life.

3. Precision Machining Capability

Look for:

- CNC grinding

- Wire cutting accuracy

- Consistency in tolerance

Contact GUNRI ,Your trust Extrusion Die Punch manufacturer