Factors Affecting the Quality of Mold Components

The quality of mold components is influenced by various factors, as outlined below:

- Rational Design of Mold Components

Designers should thoroughly understand the user’s requirements, working conditions, and the pressure casting force before proceeding with mold component design. Material selection should be based on these requirements, considering the casting performance of the chosen material. In mold component design, it is crucial to meet usage requirements while ensuring simplicity in casting structure. Proper and uniform wall thickness, along with necessary mold slopes, must be maintained to avoid defects such as pits, pores, shrinkage, underfill, stretching marks, cracks, and deformations. Reasonable dimensional accuracy requirements should be specified to avoid unnecessary complications in mold design, processing, process condition formulation, and management, as well as to prevent the production of large quantities of non-conforming products.

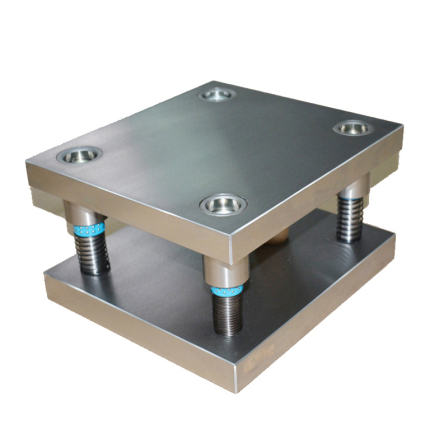

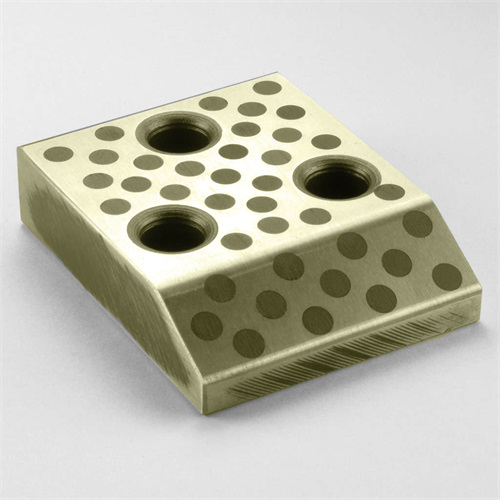

- Mold Structure, Processing Precision, and Mold Material

The selection of mold components for pressure casting is closely related to product quality through considerations of casting, mold design, processing, and material selection. If the mold structure is not rational, it becomes challenging to produce qualified products regardless of the adopted measures. Moreover, mold material properties, processing precision, surface roughness, processing marks, heat treatment-induced microcracks, nitride layer thickness, and mold assembly all affect product quality and mold service life.

- Shrinkage Rate of Mold Component Materials

The shrinkage rate of casting materials, usually expressed as an average percentage or a certain variation range percentage, plays a vital role in mold component design. For high-precision castings and mold designs, special attention should be paid to material shrinkage selection. Testing of the mold may be necessary to obtain required data before designing and manufacturing large-scale molds.

In conclusion, the quality of mold components is influenced by various factors. To ensure better quality, designers should opt for optimal structural schemes during the design process. Designers must consider both technical requirements and structure, ensuring they are in line with mold manufacturing feasibility and processability.