Factors Affecting the Quality of Mold Components

Factors Affecting the Quality of Mold Components:

- Rationality of Component Design:

Designers should fully understand the user’s requirements and working conditions, including the situation of the die-casting force. Based on these requirements and the working environment, they should select suitable materials and understand their die-casting performance. In the design of precision mold components, it is crucial to meet usage requirements while keeping the die-casting structure as simple as possible. The wall thickness should be appropriate and uniform, and necessary mold slopes should be included. Failing to do so can lead to defects such as pits, pores, shrinkage, insufficient pressure, stretch marks, cracks, and deformation in the castings. The requirements for casting dimensional accuracy should be reasonable to avoid unnecessary complications in mold design, mold processing, process condition formulation, and management, which can result in a large number of defective products.

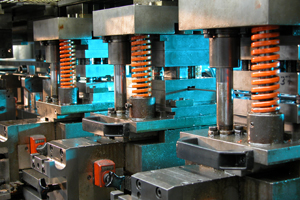

- Mold Structure, Processing Precision, and Mold Material Selection:

Die-casting quality is closely related to die-casting, mold design, processing, and mold material selection. If the mold structure is unreasonable, no measures taken during the process can ensure qualified products. Additionally, the mold material for precision mold components must be resistant to heat and wear. Factors such as mold processing precision, surface roughness, machining marks, small cracks from heat treatment, nitride layer thickness, and mold assembly all impact product quality and mold life.

- Shrinkage Rate of Component Materials:

The shrinkage rate of casting materials is generally expressed as an average percentage or a percentage within a certain variation range, typically choosing the material’s average shrinkage rate. For high-precision die-castings of precision mold components, special attention should be given to the selection of material shrinkage rates. If necessary, a test mold can be used first to obtain the required data, which can then be applied to the design and manufacturing of large-scale molds for production.