Factors Leading to Deformation in Machined Components

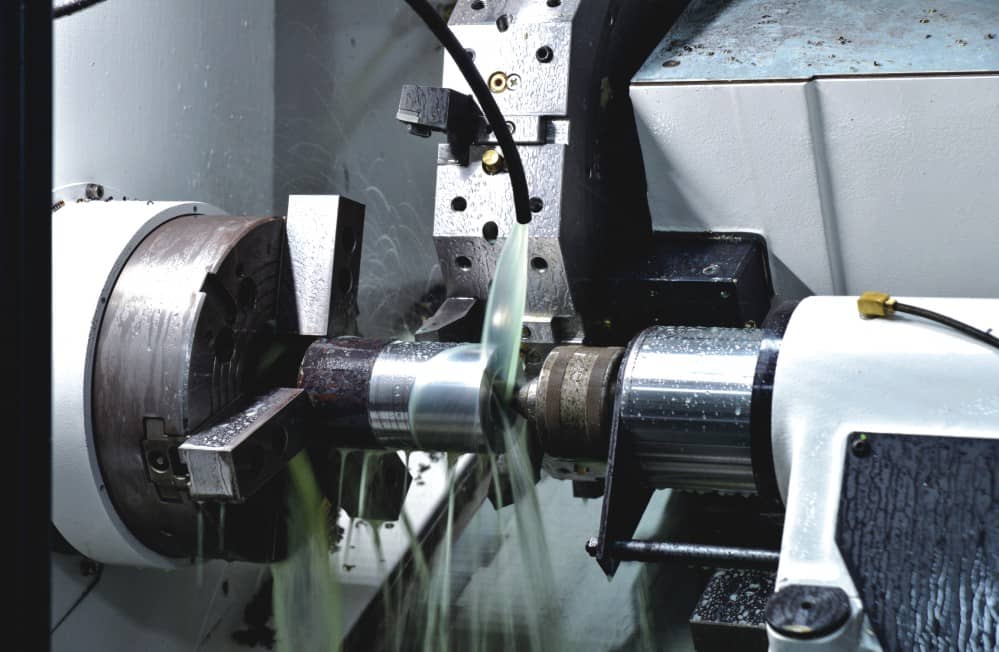

Machined components, such as ball cages for dies and Ball Guide Post Sets, can undergo deformation during the machining process. Several factors contribute to this phenomenon:

1. Elastic Deformation due to External Forces: Elastic deformation in components can result from external forces applied during machining. Several reasons contribute to this in machining processes:

- Thin internal structures: Components with thin internal structures require precise positioning and clamping during machining to prevent deviations from design specifications.

- Uneven fixtures: Inconsistent lathe beds and fixtures can lead to uneven forces on component sides, causing translation and deformation during cutting.

- Poor component positioning: Inadequate component positioning during machining reduces their stiffness and strength.

- Cutting forces: The presence of cutting forces is a significant factor leading to elastic deformation in components.

2. Changes in Precision due to Internal Forces: During machining on lathes, three-jaw and four-jaw chucks are used to clamp components and apply centrifugal force for machining. The clamping force must match the machine’s cutting force to prevent loosening and minimize internal radial force impact. However, when these chucks are loosened, machined components may deviate significantly from their original shape.

3. Deformation Issues after Heat Treatment: Thin-film mechanical components are susceptible to warping after heat treatment, given their larger length and diameter. Warping, dimpling, and increased planar deviation may occur due to various external factors. These deformations result from changes in internal stress within components after heat treatment.

In conclusion, preventing component deformation during machining, including ball cages for dies and Ball Guide Post Sets, necessitates careful consideration of various factors and the implementation of appropriate measures. This ensures that components maintain their intended shape and function as intended in the final product.