FAQ Guide for DIN 6325 Dowel Pins

Table of contents

- 1. What does DIN 6325 mean?

- 2. What is the material specification of DIN 6325?

- 3. What is the equivalent of DIN 6325?

- 4. What is the tolerance of ISO 8734 hole?

- 5. Common Sizes of DIN 6325 Dowel Pins:

- 6. Applications of DIN 6325 Dowel Pins:

- 7. Benefits of DIN 6325 Dowel Pins:

- 8. How to Select the Right DIN 6325 Dowel Pin:

1. What does DIN 6325 mean?

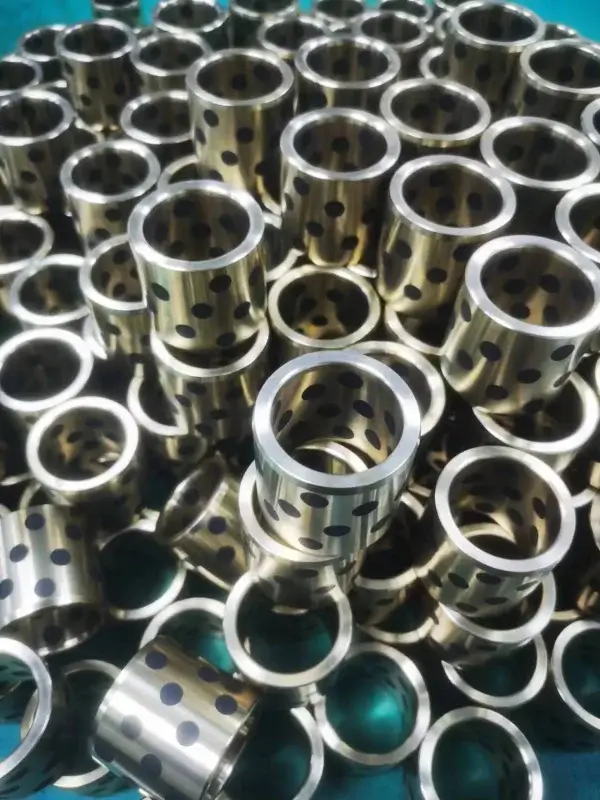

DIN 6325 refers to headless parallel pins that are hardened and ground to precise diameters. These dowel pins have one end chamfered at a 15° angle and radiused for easy insertion, while the other end is radiused.

2. What is the material specification of DIN 6325?

DIN 6325 dowel pins can be made from various materials including low carbon steel, nickel stainless steel, chrome stainless steel, alloy steel, and aluminum.

3. What is the equivalent of DIN 6325?

DIN 6325 is equivalent to ISO 8734 and DIN 7979. These standards ensure compatibility and interchangeability with similar dowel pins.

4. What is the tolerance of ISO 8734 hole?

For the parallel pin ISO 8734, the common standard inch or imperial dowel pin has a diameter tolerance of -0.00 / +0.0002. The length tolerance is +/- 0.010. In metric units, the tolerance is +0.012mm / -0.004mm with the length specification adhering to the pin length.

5. Common Sizes of DIN 6325 Dowel Pins:

DIN 6325 dowel pins are available in various sizes. The standard diameter ranges from 1/32″ to 1/2″ (1 mm to 12 mm), and the length ranges from 3/32″ to 1-1/2″ (3 mm to 50 mm).

6. Applications of DIN 6325 Dowel Pins:

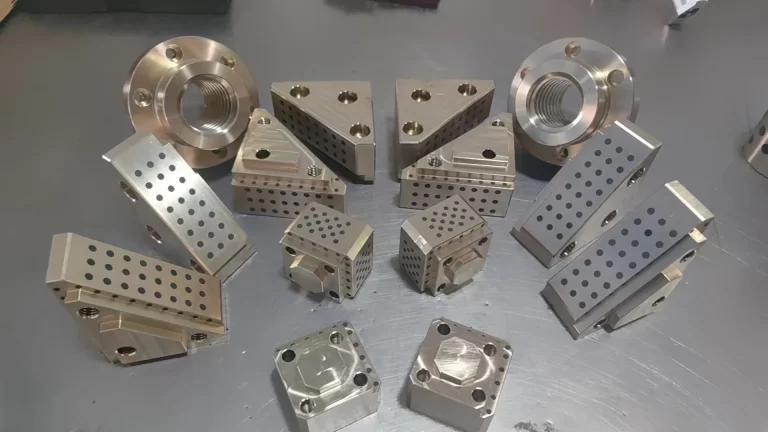

DIN 6325 Locating Pins are headless parallel pins that are hardened and ground to precise diameters. One end is chamfered at a 15° angle and radiused for easy insertion, while the other end is radiused.

Used in situations with impact and vibration, it can substitute for certain cylindrical pins, taper pins, split pins, or shafts.

Precision Alignment

DIN 6325 Locating Pins find widespread applications in manufacturing and engineering, providing high precision. Their design ensures accurate alignment between mechanical components, maintaining stable positions during assembly and operation.

Mechanical Assemblies

In mechanical assemblies, DIN 6325 Locating Pins serve as precision positioning elements, ensuring the accuracy of relative positions between components. This is crucial in assembly processes that demand high precision, such as in automotive manufacturing, aerospace, and other precision industrial fields.

Connection and Fixation

Used for connecting and fixing mechanical components, Locating Pins with DIN 6325 specifications offer robust design and precise diameters. The hardened treatment ensures durability and long-term reliability, suitable for applications subject to certain loads and pressures.

Automation Systems

DIN 6325 Locating Pins play a crucial role in automation systems, ensuring precise positioning and stability of machine components. This is essential for enhancing production efficiency, reducing machine failures, and ensuring consistency.

Industrial Equipment Maintenance

In the maintenance and repair of industrial equipment, DIN 6325 Locating Pins are commonly used as standard components for replacement and repair work. Their standard dimensions and material choices make them universal substitutes, simplifying maintenance tasks.

7. Benefits of DIN 6325 Dowel Pins:

It possesses elasticity, tightly pressing against the hole wall after insertion, and is not prone to looseness. The precision requirement for the pin hole is relatively low, ensuring good interchangeability and allowing for multiple installations and removals.

However, it exhibits lower rigidity and is not suitable for high-precision positioning. When handling larger loads, several pins can be stacked together for use, and the notches of adjacent inner and outer pins should be staggered by 180 degrees.

- Precise dimensions for accurate alignment.

- Hardened and ground for durability.

- Chamfered and radiused ends aid in easy insertion.

8. How to Select the Right DIN 6325 Dowel Pin:

Consider the specific application requirements, such as size, material, and tolerance, to choose the appropriate DIN 6325 dowel pin for your needs.

This FAQ guide provides essential information about DIN 6325 dowel pins, ensuring users have a comprehensive understanding of their specifications, equivalents, tolerances, and applications.