Guide Bushings: The Tiny Component That’s Making or Breaking Your Stamping Operations

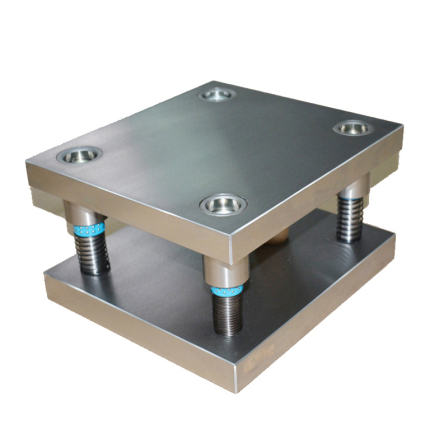

You’ve invested in top-tier presses, precision-cut punches, and state-of-the-art tool steels. But if you’re still battling misaligned dies, premature wear, or costly downtime, there’s one culprit you might be overlooking: the guide bushing.

In stamping—a process where every millimeter counts—this small, often unassuming component is the silent guardian of consistency. Let’s unpack why it deserves a spot at the center of your tooling strategy.

Why Alignment Isn’t Just a “Nice-to-Have”—It’s a Production Lifesaver

Imagine a high-speed press slamming down with tons of force. The punch and die glide together, cutting, bending, or shaping metal. Now, remove the guide bushing. Suddenly, that “choreographed” motion turns into a wobbly free-for-all.

Guide bushings aren’t just “alignment tools”—they’re the backboneof precision. Their job? To keep the punch and die perfectly synced, even when the press vibrates, metal expands from heat, or the line speeds up.

A single millimeter of misalignment might seem trivial. But in stamping:

- It creates burrs that ruin part quality (and trigger rework).

- It causes uneven wear on punches and dies (shortening their lifespan by 30-50%).

- Worst case: It leads to catastrophic tool damage—think cracked dies or snapped punches—halting production for days.

In short: No guide bushing = no reliable operation.

Beyond Alignment: How Guide Bushings Supercharge Your Bottom Line

Guide bushings don’t stop at keeping things straight. Their impact ripples across your entire operation:

1. They Extend Tool Life (and Save You Money)

Every stamping cycle subjects punches and dies to lateral forces—scraping, grinding, and stress. Guide bushings act like shock absorbers, absorbing these forces and reducing friction.

Example: A client in automotive stamping switched to self-lubricating guide bushings. Over 6 months, their punch wear dropped by 40%, and die replacement costs fell by $12k/month.

2. They Boost Part Quality (and Keep Customers Happy)

In industries like aerospace or medical devices, “close enough” isn’t an option. Guide bushings ensure the punch hits the die in the exactsame spot, cycle after cycle.

Result? Fewer defects, less rework, and parts that pass quality checks on the first try.

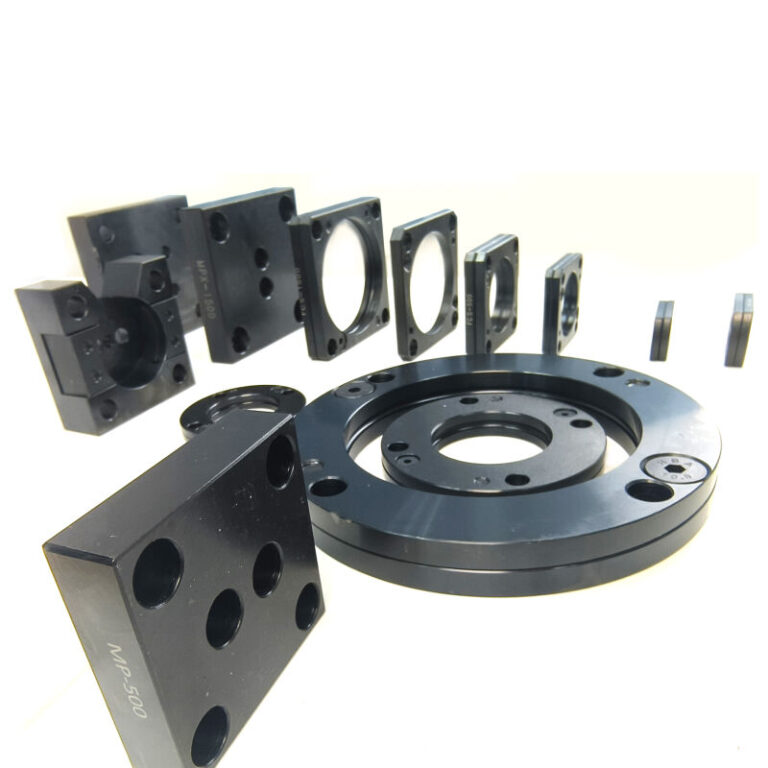

3. They Protect Your Biggest Investment: Your Tooling

Stamped dies cost tens of thousands (or millions) of dollars. A single misalignment event can damage not just the punch or die, but the entire tool set.

Guide bushings act as a first line of defense, preventing the punch from slamming into the die edge (a common cause of chipping or cracking). Think of them as insurance for your tooling budget.

3 Design Tips to Maximize Your Guide Bushing’s Impact

Not all guide bushings are created equal. To get the most out of them, focus on these three factors:

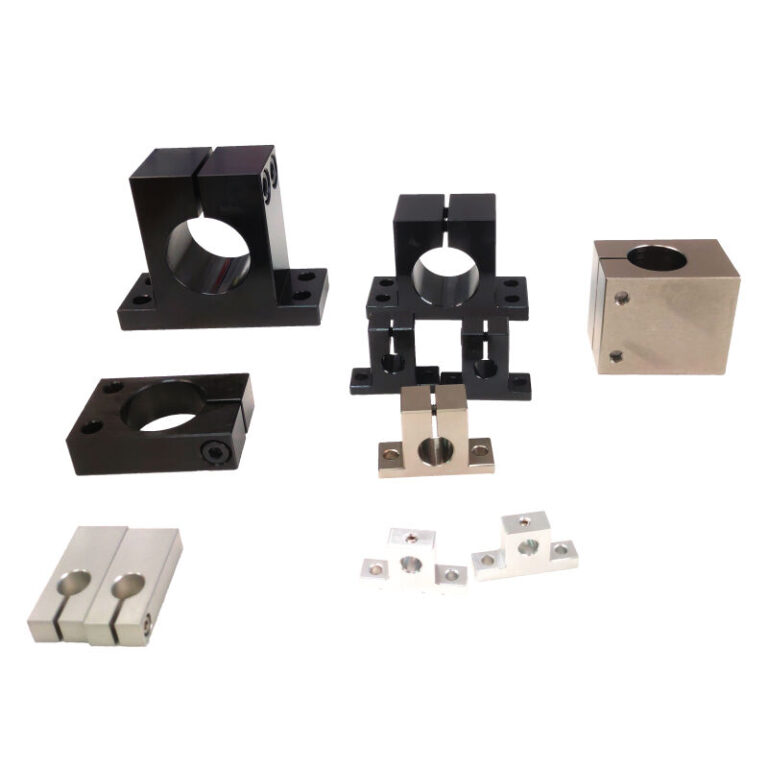

1. Material Matters (Match It to Your Application)

- Bronze-lined bushings: Ideal for high-friction environments (e.g., stamping stainless steel). They reduce wear by 20-30% compared to plain steel.

- Self-lubricating designs: Perfect for high-speed lines where maintenance downtime is costly. They eliminate the need for frequent oiling.

- Composite bushings: Great for corrosive environments (e.g., stamping coated metals) — they resist rust and chemical damage.

2. Tight Tolerances = Consistent Performance

Even a 0.001” deviation in bushing dimensions can throw off alignment. Work with suppliers that offer precision machining (tighter than ±0.002” is ideal for most stamping applications).

3. Compatibility with Your Press

High-speed presses (1,000+ strokes/min) need bushings that handle rapid vibration. Heavy-duty presses require bushings with higher load capacity. Always test bushings under yourpress conditions—don’t assume “one size fits all.”

Final Thought: Don’t Underestimate the “Small Stuff”

In manufacturing, the biggest breakthroughs often come from optimizing the smallest components. A well-designed guide bushing won’t just fix misalignment—it will streamline your production, cut costs, and keep your customers coming back.