How do self-lubricated bronze bearings work?

Unlocking the Mechanics of Self-Lubricating Bronze Bearings

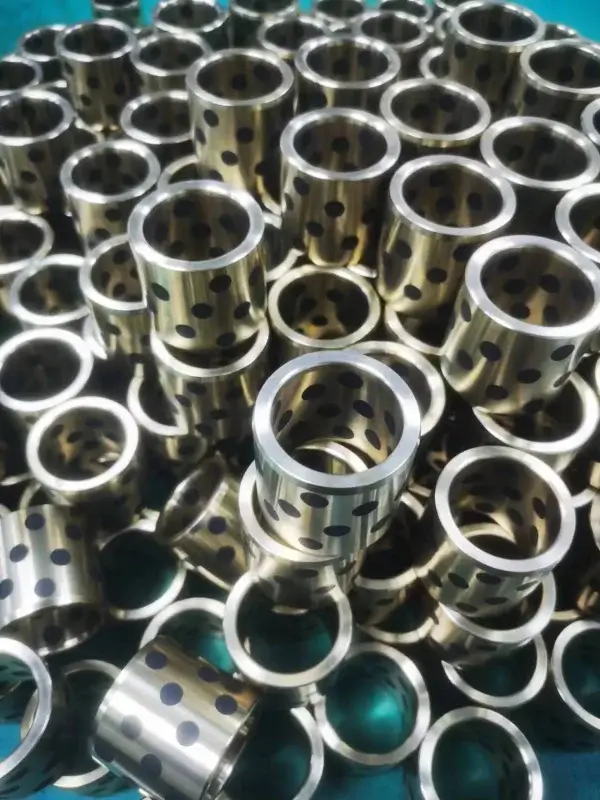

In the realm of machinery, the pivotal role of bearings in ensuring seamless movement and reducing friction between moving parts cannot be overstated. Today, let’s delve into the intriguing world of self-lubricating bronze bearings – an indispensable component for machines with dynamic elements.

The Ingenious Science Behind Self-Lubricating Bronze Bearings

Self-lubricating bronze bearings are ingeniously engineered to minimize maintenance requirements and enhance overall performance. The crux of their efficiency lies in their construction: these bearings house a lubricant within their sliding layer. This design guarantees a consistent and reliable lubrication throughout the lifespan of the bearing, drastically reducing the need for external lubrication. It’s a paradigm shift in machine maintenance, providing a more efficient and hassle-free solution.

Choosing the Right Self-Lubricating Slide Bearings

Selecting the appropriate bearings for your machinery is a critical decision. Self-lubricating bronze bearings are available in various sizes and configurations, catering to a broad spectrum of applications. Opting for the right bearing ensures optimal performance and longevity for your machine.

Why Opt for Self-Lubricating Bronze Bearings?

- Reduced Maintenance: The self-lubricating feature diminishes the need for constant attention, saving valuable time and resources.

- Extended Lifespan: Consistent lubrication minimizes wear and tear, extending the operational life of the bearing.

- Enhanced Performance: Smoother operation and reduced friction contribute to improved overall machinery efficiency.

- Versatility: Suited for diverse applications, these bearings can adapt to varying operating conditions and loads.

In summary, self-lubricating bronze bearings stand out as a remarkable innovation in the domain of machinery components. Their self-lubricating ability not only simplifies maintenance but also guarantees prolonged lifespan and enhanced performance for your equipment. Whether you operate in industrial machinery, automotive, or any field with mechanical components, considering self-lubricating bronze bearings could prove to be a strategic decision, elevating efficiency while minimizing operational challenges.

Addressing Lubrication Challenges with Self-Lubricating Bronze Bearings

Insufficient lubrication remains a leading cause of bearing failure in industrial settings, often stemming from inconsistent or inadequate application. This deficiency results in heightened stress and friction, ultimately leading to bearing failures. Such failures can range from minor inconveniences to major disruptions in productivity, presenting substantial challenges for businesses. This prevalent issue has triggered a concerted industry response, with an excessive approach to bearing lubrication becoming common, irrespective of actual necessity. In response to this, the self-lubricating bronze bearing has emerged as a groundbreaking solution.

On the surface, self-lubricating bronze bearings may seem indistinguishable from their non-self-lubricating counterparts. However, the key distinction lies in their intricate design and functionality. These bearings are crafted with a metallic composition boasting an impressive porosity rate of nearly 25%. This high porosity rate facilitates the seamless transfer of liquids, a critical aspect of the self-lubricating process. During manufacturing, these bearings are infused with a specialized oil, gradually released during operation to ensure consistent and automatic lubrication. Consequently, manual lubrication becomes redundant and may even be detrimental, potentially compromising the metal’s integrity. This innovative bearing technology not only streamlines maintenance but also enhances the longevity and performance of industrial machinery.