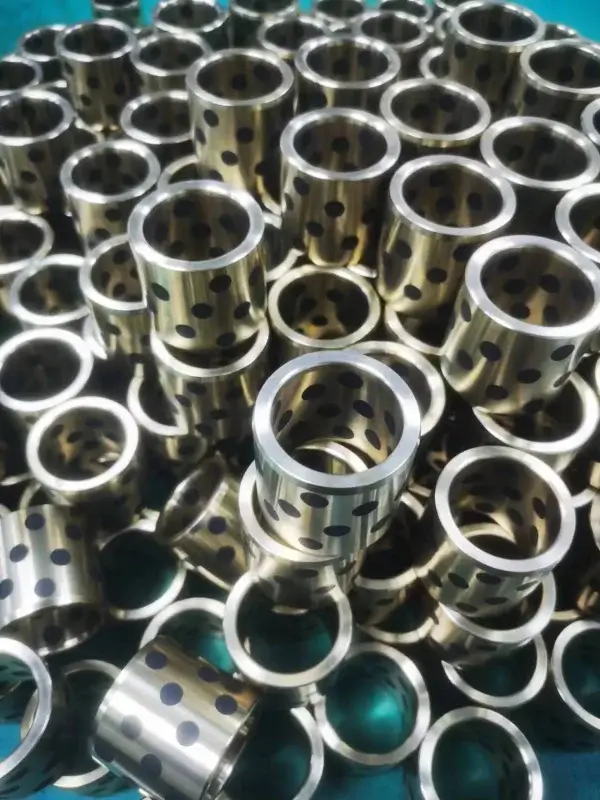

How Often Should Guide Pins and Bushings Be Replaced?

The lifespan of guide pins and bushings depends on various factors, including the material of the bushings, the frequency of punches per minute, regular maintenance, and more. Therefore, it is challenging to provide a specific lifespan.

For instance, in the case of plastic mold guide pins and bushings, as long as proper lubrication is maintained, preventing them from running dry and lacking oil, they should typically last for several hundred thousand cycles without major issues.

Factors Influencing Lifespan:

- Material Quality:

- The quality of materials used for guide pins and bushings is a crucial factor. High-quality materials can contribute to a longer lifespan.

- Operating Conditions:

- The environmental conditions, such as temperature, humidity, and exposure to corrosive elements, can impact the longevity of guide pins and bushings.

- Maintenance Practices:

- Regular lubrication and maintenance play a vital role in extending the lifespan of guide pins and bushings. Proper care can prevent premature wear and damage.

- Load and Frequency:

- The load capacity and the frequency of mold cycling or punching also influence the wear and tear on guide pins and bushings.

Plastic Mold Guide Pins and Bushings:

For plastic mold guide pins and bushings, if adequate lubrication is ensured, preventing them from running dry and becoming excessively dry, they should generally withstand several hundred thousand cycles without significant issues.

General Guidelines:

- Regularly inspect guide pins and bushings for signs of wear, damage, or lack of lubrication.

- Follow manufacturer recommendations for lubrication intervals and types.

- Consider replacement if there are visible signs of wear, scoring, or other damage.

In summary, the lifespan of guide pins and bushings is influenced by several factors. Regular maintenance, proper lubrication, and attention to operating conditions are essential for maximizing their longevity. Inspecting and replacing them as needed based on visual assessments and adherence to manufacturer guidelines will contribute to the overall efficiency and reliability of the mold system.