How should the design and selection of mold springs be calculated?

Formula for Calculating Mold Spring Pressure

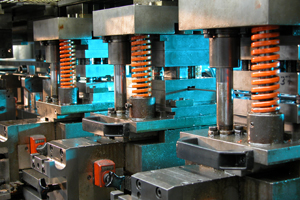

When designing and selecting mold springs, the most fundamental criterion is whether the spring force can ensure smooth production of the mold. The most widely used and critical components in molds are the ejector plate return springs and the slider limiting springs. When the spring is used as auxiliary for mold opening, there are fewer restrictions.

To ensure the smooth return of the ejector plate, the spring force in the preloaded state of the return spring should be greater than 2.5 times the weight of the ejector plate.

When using spring limiting for the slider, the spring force on the non-gear side slider should be set at 2 to 2.5 times the weight of the slider, and for other direction sliders, the preloaded spring force should be no less than the weight of the slider.

Both cases use the following formulas:

Spring Total Length = (Stroke + Preload) / Compression Ratio

Spring Load = Spring Stiffness × Compression Amount

Where:

- Spring Total Length: Length of the spring in its free state.

- Stroke: The distance that needs to be moved, determined by the actual needs of the mold.

- Preload: Precompressed length, usually set at 10% of the total length.

- Compression Ratio: A coefficient that, when different, results in different spring lifespans.

- Spring Load: Can be understood as the spring force.

- Spring Stiffness: The ratio of the increment of spring force to the increment of deformation. It can be understood as the ratio of the increase of force by 1000N to the compression length of the spring.

- Compression Amount: The length by which the spring can be compressed.

The mold spring pressure length refers to the length of the force the spring experiences during mold closing and opening. It can be calculated based on parameters such as injection pressure, mold opening and closing force, spring constant, and maximum spring displacement.

Assuming the injection machine injection pressure is F1, mold opening and closing force is F2, spring constant is K, and maximum spring displacement is Xmax, then the force length L the spring experiences can be calculated as: L = Xmax + (F1 – F2) / K.

Taking an injection mold as an example:

Injection machine injection pressure is 500kg, mold opening and closing force is 800kg, constant is 0.2mm/kg, coil diameter is 10mm, wire diameter is 2mm, number of coils is 15, and maximum displacement is 50mm.

According to the above formula: Spring free length L0 = (10 + 2) * 15 = 180mm, force length L = 50 + (500 – 800) / 0.2 = 150mm. Therefore, the spring deformation under force is 30mm, and the spring force is F = 30 * 0.2 = 6kg.