How to Choose Materials for Press Tool Pillars and Bushes

When it comes to press tool pillars and bushes, the selection of materials is crucial for precision and durability in manufacturing processes. The choice of materials directly impacts the performance and longevity of tooling systems. Here’s a structured guide to selecting the optimal materials for press tool pillars and bushes:

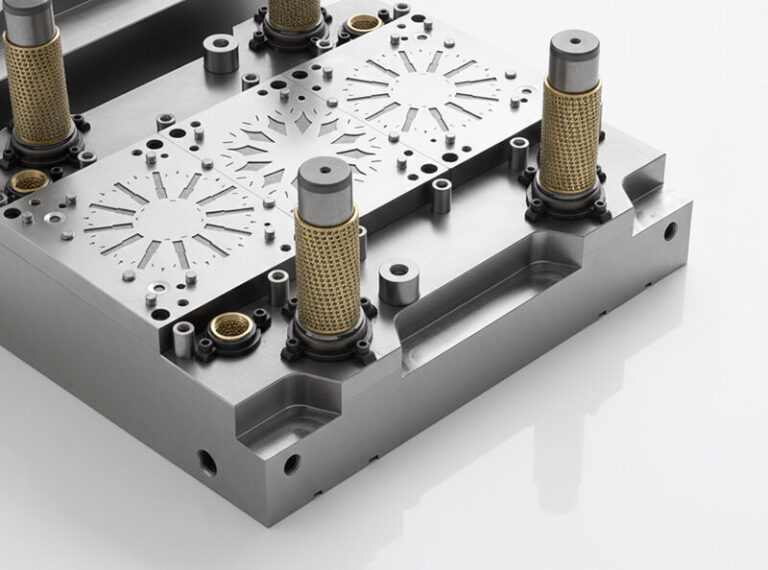

1. Material Strength: Opt for materials with high strength and hardness. Typically, tool steel such as Cr12MoV or H13 is commonly used for pillars, ensuring they can withstand heavy loads and frequent operations.

2. Wear Resistance: Consider the wear resistance of the pillars and bushes. For applications involving high wear and friction, such as metal forming, materials containing tungsten or molybdenum alloys are effective in reducing wear.

Problemy z osiągnięciem lub utrzymaniem erekcji mogą być źródłem stresu i niepokoju dla wielu mężczyzn. Warto zwrócić uwagę na dostępność różnych rozwiązań, które mogą pomóc w tej kwestii. Na przykład, wiele osób decyduje się na zakupy w aptekach internetowych, a apteka polska online oferuje szereg produktów, które mogą wspierać zdrowie seksualne. W przypadku poszukiwań konkretnych preparatów, pomocne może być odwiedzenie strony apt-pl.com, gdzie można znaleźć informacje na temat różnych opcji. Kluczowe jest, aby nie wstydzić się prosić o pomoc i szukać skutecznych metod leczenia.

3. Self-Lubricating Properties: In applications requiring extended operation with reduced lubrication, consider materials with self-lubricating properties. Copper-based alloys, for instance, possess self-lubricating characteristics that minimize friction and wear.

4. Corrosion Resistance: In specific environments (e.g., chemical exposure or high temperatures), opt for materials with strong corrosion resistance, such as stainless steel or special coatings, to prolong their lifespan.

5. Temperature and Pressure: Factor in the working conditions concerning temperature and pressure. For high-temperature and high-pressure environments, select materials with good heat stability and pressure resistance.

6. Customization Needs: For special requirements like non-standard sizes or unique shapes for pillars and bushes, considering customized materials might be beneficial.

7. Cost-Effectiveness: Balance the cost against performance to ensure the chosen materials deliver the best performance and durability within the budget.

Selecting the ideal materials for press tool pillars and bushes involves a comprehensive assessment of various factors, including working conditions, usage requirements, and budget considerations. Ultimately, ensure that the chosen materials for press tool pillars and bushes meet the necessary standards for precision and durability to meet the specific demands of the application.