How to Use High-Force Nitrogen Gas Springs in Stamping and Forming Dies

Nitrogen gas springs, also known as gas cylinders, are elastic components that seal high-pressure nitrogen gas within a robust container. When external force is applied, the piston rod compresses the gas. Once the force is removed, the stored gas energy drives the piston to rebound.

Compared with conventional elastic components like coil springs, rubber, or air cushions, nitrogen gas springs offer several advantages: compact size, space-saving in molds, and stable output force. They contribute to improved part quality, easy installation and adjustment, and overall enhanced mold precision, efficiency, and service life.

1. Key Features of Nitrogen Gas Springs

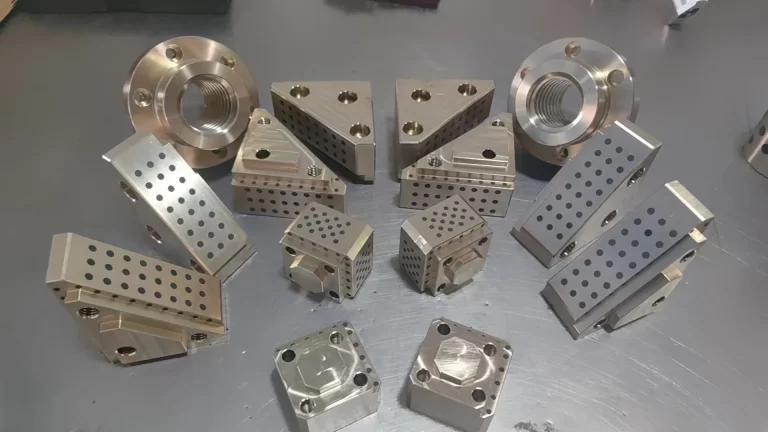

Nitrogen gas springs use compressed nitrogen as the working medium. By adjusting the initial internal pressure or the internal volume, different force outputs or pressure curves can be achieved. Based on internal sealing mechanisms, nitrogen gas springs can be categorized into piston type or plunger type, as well as independent or non-independent designs.

Key characteristics include:

- Compact Size & High Force Output

Nitrogen gas springs provide strong initial force in limited space, without requiring preloading before use. - Stable Spring Force

The force increase during operation is minimal, maintaining a relatively constant output. The force level and point of application can be precisely adjusted to match process needs, facilitating mold design and tuning. - Enhanced Product Quality & Reduced Downtime

Nitrogen gas springs ensure consistent pressure during stamping, improving part quality and shortening mold changeover time—enhancing productivity and reducing costs. - Versatile Power Source

They can serve as a passive power source, and are easy to apply across various mold designs.

2. Applications of Nitrogen Gas Springs in Different Processes

- Drawing and Forming

In deep drawing operations, nitrogen gas springs deliver accurate and consistent blank-holding force. The pressure and contact point can be quickly adjusted. This improves product quality and minimizes wrinkling and tearing in metal forming. - Bending Operations

In bending applications, the force provided is easily calculated and stable. No preloading is needed to achieve high initial force. This helps control both longitudinal and transverse springback in metal parts. - Cam Slider Return

Nitrogen gas springs enhance the reliability and smoothness of cam return motion in progressive dies, reducing the need for frequent disassembly and replacement. - Punching, Ejecting, and Forming

During blanking, part ejection, or forming, nitrogen springs enable uniform contact of stripper and ejector plates, ensuring balanced force and reliable part removal.

3. Precautions for Installing and Using Nitrogen Gas Springs

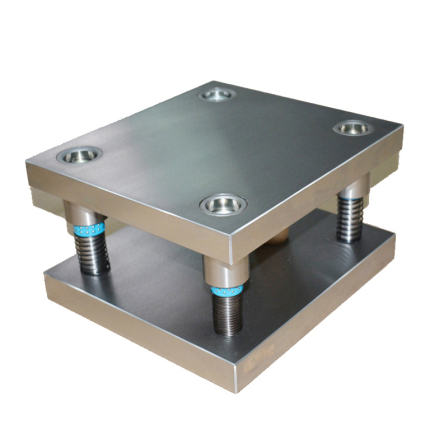

- Proper Mounting

Gas springs are typically installed via surface grooves or bottom threaded holes (sometimes countersunk). During installation, ensure that the applied force is perpendicular to the piston rod to avoid lateral loading. - Routine Inspection

Regularly check for smooth operation and inspect the piston rod for dents, scratches, or other damage. - Avoid Lubricants

No additional lubrication is needed during use. This prevents dust or oil from adhering to the piston rod, which could loosen connectors or affect performance during motion. - Keep Clean

Frequently clean the surface of the gas spring, especially removing iron shavings, moisture, or dust. Maintaining a clean piston area ensures long-term reliable operation.