Innovation and Development of Mold Components in High-End Manufacturing

In the high-end manufacturing sector, mold components serve the following purposes:

- Providing Additional Services to Form an Industrial Chain

Currently, private mold enterprises in China generally possess advanced equipment resources, and the technological application of mold components is relatively advanced. New technologies can be rapidly and widely applied in the industry, forming an industrial chain from design and manufacturing to related material production and heat treatment, with prominent integrated advantages. Due to sufficient funds and proprietary brands, hardware mold enterprises are increasing their investment in management and technological transformation, expanding the proportion of medium and high-end products, and establishing domestic sales departments to actively explore the domestic market.

- Reducing Resource Consumption and Waste Emissions

To promote pilot projects of circular economy in the domestic mold component industry, efforts should be made to reduce resource consumption and waste emissions through the principles of reduction, reuse, and resource transformation. Implementing preferential policies for national comprehensive utilization of resources, recycling and utilizing waste batteries, recycling old household appliances and furniture, bamboo and wood processing residues, mine waste, sewage treatment plant sludge, and stainless steel processing waste are actively encouraged.

- Easily Achieving Precision Machining in Fine Areas

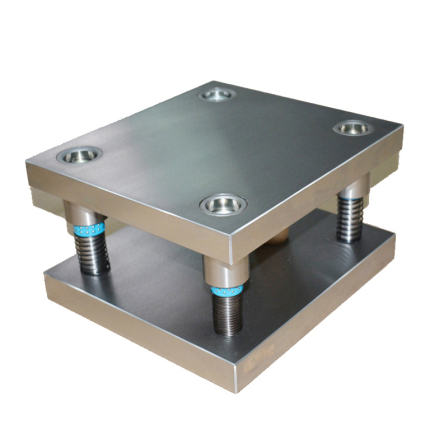

The basic requirement for mold component processing is to achieve high precision and smooth surface quality of parts, easily achieving precision machining in fine areas. When semi-finishing mold components, tolerances can be appropriately increased to save calculation time. The selected tools should be smaller than those used in finishing machining, or root clearing should be performed in advance to avoid tool collisions at corners during finishing machining.

In conclusion, these are some of the purposes of mold components in the high-end manufacturing sector. After years of continuous efforts and development, mold component enterprises have seized good development opportunities in the medium and high-end markets by utilizing heat-resistant and wear-resistant mold components, thus providing more high-end machining services to many manufacturers and enterprises.