Installation and Maintenance Best Practices for Nitrogen Gas Springs

Nitrogen gas springs are powerful and reliable components in molds and dies, but their safety and longevity depend heavily on proper installation and consistent maintenance. Following these best practices will ensure optimal performance, extend the lifespan of your nitrogen gas springs, and prioritize the safety of your operations.

Best Practices for Installing Nitrogen Gas Springs

Correct installation is the first critical step in ensuring the safe and effective operation of your nitrogen gas springs.

- Pre-Installation Checks:

- Inspect for Damage: Carefully examine each nitrogen gas spring for any signs of damage during shipping or handling, such as dents, scratches, or leaks. Do not install a damaged spring.

- Verify Part Number and Specifications: Ensure the gas spring matches the specifications required for your mold or die application (force, stroke length, mounting type).

- Check Pressure Range: Confirm that the intended operating pressure is within the safe range specified by the manufacturer.

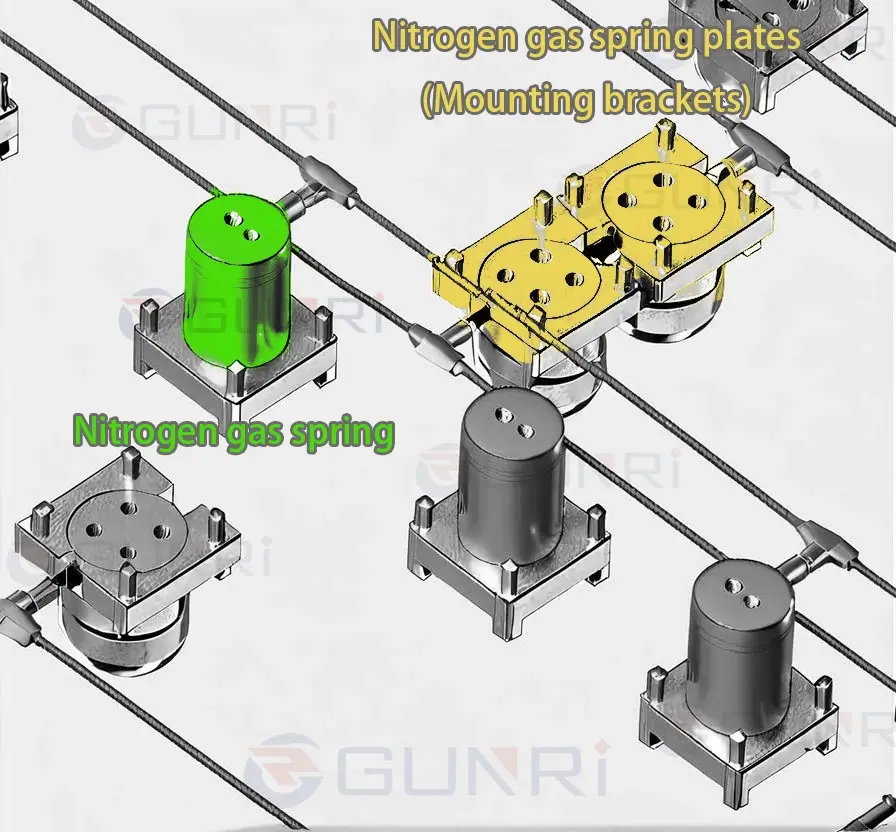

- Choosing the Correct Mounting Method:

- Select the appropriate mounting accessories and locations as per the mold or die design and the nitrogen gas spring manufacturer’s recommendations. Common mounting methods include flange mounting, threaded mounting, and bracket mounting.

- Ensure the mounting surfaces are clean and free from debris.

- Secure Mounting:

- Use fasteners of the correct size and strength. Tighten fasteners to the manufacturer’s specified torque to prevent loosening during operation.

- Ensure the nitrogen gas spring is properly aligned to avoid side loading, which can lead to premature wear and failure.

- Connecting to Pressure Systems (If Applicable):

- If your nitrogen gas spring requires connection to a pressure system for charging or adjustment, use appropriate hoses, fittings, and pressure gauges rated for the intended pressure.

- Follow the manufacturer’s instructions for connecting and charging the gas spring.

- Initial Pressure Setting:

- Charge the nitrogen gas spring to the initial pressure specified in the mold or die design, using a calibrated pressure gauge.

- Never exceed the maximum allowable pressure indicated on the gas spring.

- Safety Precautions During Installation:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- Never attempt to disassemble a charged nitrogen gas spring.

- Keep hands and tools clear of moving parts during installation.

Best Practices for Maintaining Nitrogen Gas Springs

Regular maintenance is crucial for maximizing the lifespan and reliability of your nitrogen gas springs.

- Regular Visual Inspections:

- Periodically inspect all nitrogen gas springs for any signs of leaks (indicated by oil residue), dents, corrosion, or other physical damage.

- Check the condition of seals and mounting hardware.

- Checking and Adjusting Gas Pressure:

- Regularly check the gas pressure using a calibrated pressure gauge, especially after a certain number of cycles or if performance issues are suspected.

- Adjust the pressure as needed according to the mold or die design specifications, ensuring you stay within the safe operating range.

- Lubrication (If Required):

- Some types of nitrogen gas springs may require periodic lubrication of the rod or other moving parts. Refer to the manufacturer’s recommendations for specific lubrication requirements and the type of lubricant to use.

- Proper Storage:

- When nitrogen gas springs are not in use, store them in a clean, dry environment, away from extreme temperatures and direct sunlight.

- Consider storing them in a vertical position with the rod pointing downwards to help maintain seal integrity.

- Recognizing Signs of Failure:

- Be aware of signs that a nitrogen gas spring may be failing, such as a noticeable loss of force, inconsistent performance, or unusual noises.

- Replace any gas springs that show signs of failure immediately to prevent further damage or safety hazards.

Safety First: Key Safety Guidelines

Always prioritize safety when working with nitrogen gas springs:

- Never heat or weld near a charged nitrogen gas spring.

- Do not attempt to modify or tamper with the internal components.

- Ensure that all personnel working with nitrogen gas springs are properly trained on their safe handling and operation.

- Follow the manufacturer’s safety guidelines and recommendations at all times.

Conclusion

Proper installation and consistent maintenance are essential for ensuring the safe, reliable, and long-lasting performance of nitrogen gas springs in your molds and dies. By adhering to these best practices, you can minimize downtime, maximize the lifespan of your components, and maintain a safe working environment.