Maintaining and Extending the Lifespan of Spring Probes

Spring probes, also known as pogo pins or spring-loaded contacts, are vital components in various industries, including electronics, telecommunications, aerospace, and more. These tiny but powerful devices serve the crucial role of establishing electrical connections in a wide range of applications. To ensure the longevity and reliability of your spring probes, proper maintenance and care are essential. In this comprehensive guide, we will explore key steps and best practices for maintaining and extending the lifespan of spring probes.

Table of contents

The Significance of Spring Probes

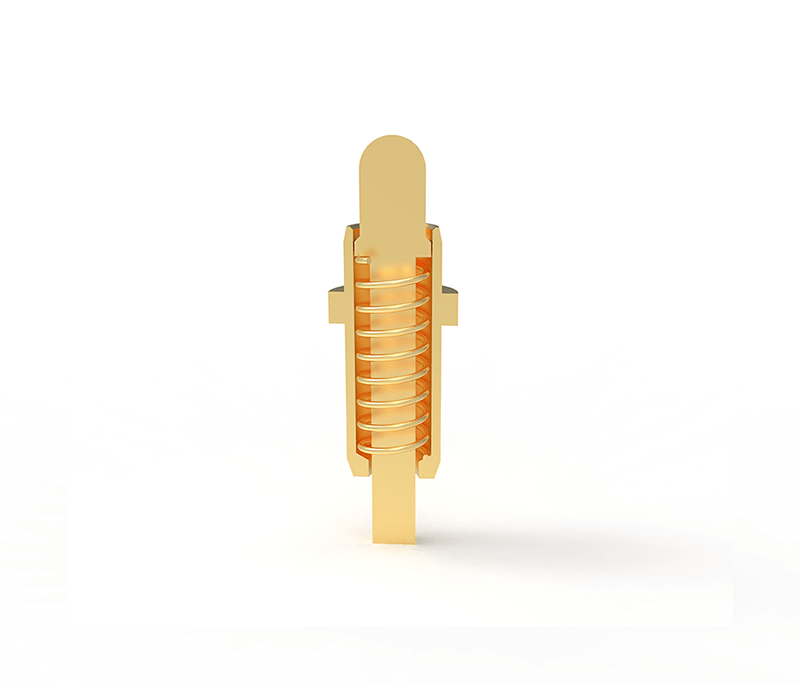

Spring probes are commonly used in applications where electrical connections need to be made and remade repeatedly, such as test and measurement equipment, PCB testing, connectors, and battery contacts. They consist of a spring-loaded plunger encased in a barrel and are designed to provide a reliable electrical connection while withstanding thousands to millions of cycles. Proper maintenance is crucial to ensure they continue to perform effectively over time.

Key Steps for Maintaining Spring Probes

Regular Cleaning: Dust, debris, and contaminants can accumulate on the tips of spring probes, leading to poor electrical contact and increased wear. Regularly clean the probe tips using a lint-free cloth, isopropyl alcohol, or a specialized contact cleaner. Ensure that the probes are disconnected from the power source before cleaning.

Visual Inspection

Periodically inspect the condition of the spring probes. Look for signs of damage, corrosion, or excessive wear. Any damaged or worn-out probes should be replaced promptly to prevent further damage to the device under test (DUT) or the test fixture.

Lubrication

Lubrication is essential for reducing friction and wear during contact cycling. Apply a small amount of contact grease or lubricant to the probe tips using a fine brush or applicator. Be cautious not to overapply, as excess lubricant can attract contaminants.

Avoid Overloading

Spring probes have defined electrical and mechanical specifications, including current-carrying capacity and maximum insertion force. Ensure that these specifications are not exceeded during use, as overloading can lead to premature failure.

Proper Storage

When not in use, store spring probes in a clean and dry environment. Consider using protective caps or covers to prevent dust and contaminants from settling on the probe tips.

Replace Worn Parts

Over time, the springs and barrels of spring probes may wear out due to repeated cycling. Manufacturers often provide replacement parts, such as springs and plungers, which can be easily replaced to extend the probe’s lifespan.

Calibration and Testing

Periodically calibrate and test your test fixtures or equipment to ensure that the spring probes are functioning correctly. Any deviations from expected performance should prompt further inspection and maintenance.

Environmental Considerations

Be aware of the operating environment. Extreme temperatures, humidity, or corrosive atmospheres can accelerate wear and corrosion of spring probes. Consider using probes designed for specific environmental conditions when necessary.

Training and Awareness

Ensure that personnel handling equipment with spring probes are trained in proper maintenance procedures and are aware of the probes’ limitations and specifications.