Material Thickness and Composition: Why They Drastically Affect Punch-to-Die C

Selecting the correct punch-to-die clearance is one of the most critical parameters in stamping tool design. However, there is no universal value—clearance must be adjusted based on both material thickness and compositi. These

Thic

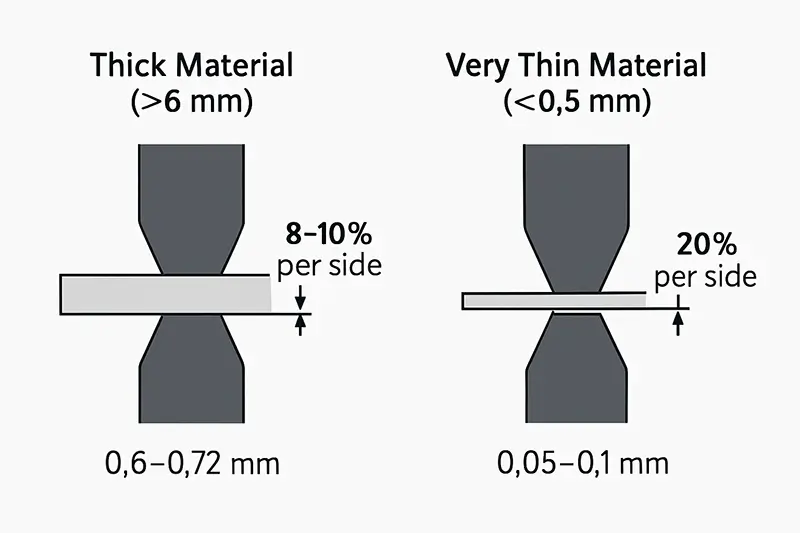

For thick materials, the standard clearance is typically 8–10% of the material thickness per.

Exampl

A 6

Adding 2% brings it to 0.72 mm—already a large gap for tooling.

This is why clearance percentages for thick stock remain low: a small percentage increase translates into a large absolute value.

Very Thin Materials (<0.5 mm)

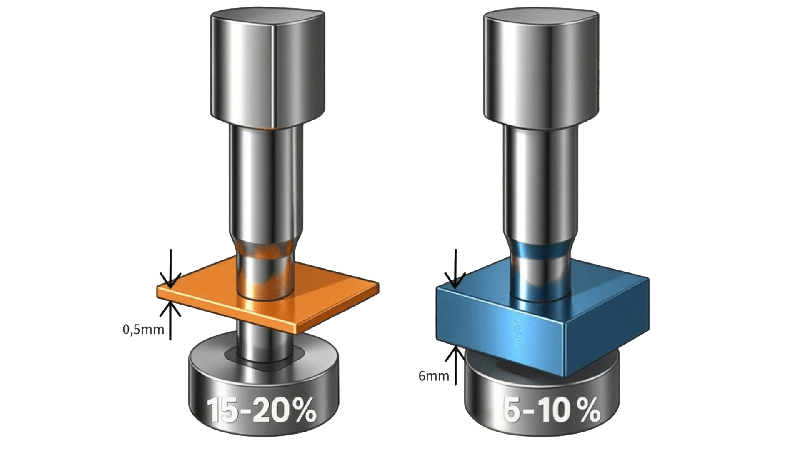

In contrast, thin materials require much higher clearance percentages. Traditional values (5–10%) tend to cause stretching, burring, or deformation. To ensure clean shearing, higher percentages are used, especially for difficult materials.

- Aluminum: 15–20% per side

- Stainless steel and spring steel: Up to 25% per side

Despite the high percentage, the actual clearance remains very small.

Example:

A 0.5 mm sheet at 20% results in just 0.10 mm clearance per side.

This illustrates a critical concept: higher clearance percentages on thin material do not equate to large clearances in absolute terms.

Conclusion

The same percentage of clearance yields vastly different real-world gaps depending on the material thickness. For thick stock, small percentage changes make a big difference. For thin stock, high percentages are necessary to achieve even minimal physical clearance.

Both thickness and composition must be factored into every clearance decision to ensure optimal performance, minimize tool wear, and produce high-quality parts.