Maximizing Stamping Tool Lifespan: Expert Tips on Die Clearance and Material Selection

In the stamping industry, correctly setting the die clearance is crucial for extending the lifespan of your tools. Did you know that by adjusting this parameter properly, you can extend the life of your tools by up to 50%? In this article, we’ll explore how precise die clearance adjustments and selecting the right materials can improve tool efficiency and reduce wear.

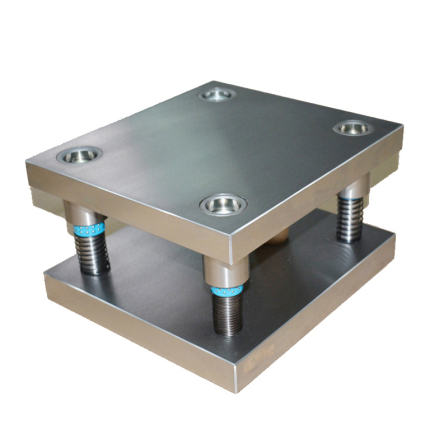

1. What is Die Clearance?

Die clearance refers to the gap between the punch and the die, typically set as 5-15% of the material thickness. This parameter is critical as it directly affects the wear of punches and dies, as well as the quality of the cut.

Example: How to Adjust Die Clearance for 2mm Steel?

For a steel thickness of 2mm, the recommended die clearance should be between 0.1mm and 0.3mm. This clearance ensures a clean cut while minimizing wear on both the punch and the die.

2. Choosing the Right Tool Steel Material

Selecting the right tool steel is essential for improving the lifespan of dies and punches. Common tool steels include A2 and M2, which offer excellent wear resistance and toughness. Specifically:

- A2 Steel: A 5% chromium tool steel that provides better toughness than 1.2379 (D2), but with slightly lower wear resistance.

- M2 Steel: A high-speed steel suitable for high temperatures and high-stress environments. However, if higher toughness is required, consider using Daido DRM3 or other advanced tool steels. These steels offer significantly higher toughness and wear resistance compared to traditional options like D2.

3. Punch Selection and Tool Performance Optimization

The type and design of the punch also affect the performance and lifespan of the tool. For instance, conical punches or punches with shear angles help reduce the force required for stamping, thus minimizing wear on the tools.

4. Regular Maintenance and Coating Applications

In addition to setting the correct die clearance, regular maintenance is equally important. Polishing punches and dies to reduce friction can significantly improve tool lifespan.

Furthermore, selecting the right coatings, such as TiN (Titanium Nitride) or DLC (Diamond-Like Carbon) coatings, can greatly enhance wear resistance, particularly in high-volume production environments.

5. Conclusion: Efficient Tool Use and Maintenance

Proper die clearance settings, choosing the right tool steels, optimizing punch design, and regular maintenance are key factors in extending the lifespan of stamping tools. Additionally, modern coating technologies play a significant role in improving tool performance and durability.