Metal Stamping vs. Engraving: Exploring Two Precision Techniques

In the world of metalworking, precision techniques are essential for creating intricate designs and parts with the utmost accuracy. Two of the most commonly used techniques for achieving high-quality metal components are metal stamping and engraving. While both methods are widely used in industries such as automotive, aerospace, and electronics, they differ significantly in terms of their processes, applications, and outcomes.

In this article, we will explore the key differences between metal stamping and engraving, including their processes, advantages, and ideal applications. By the end of this comparison, you will have a clear understanding of which technique is best suited for your specific needs.

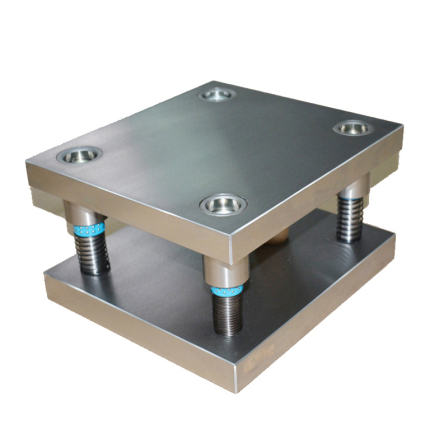

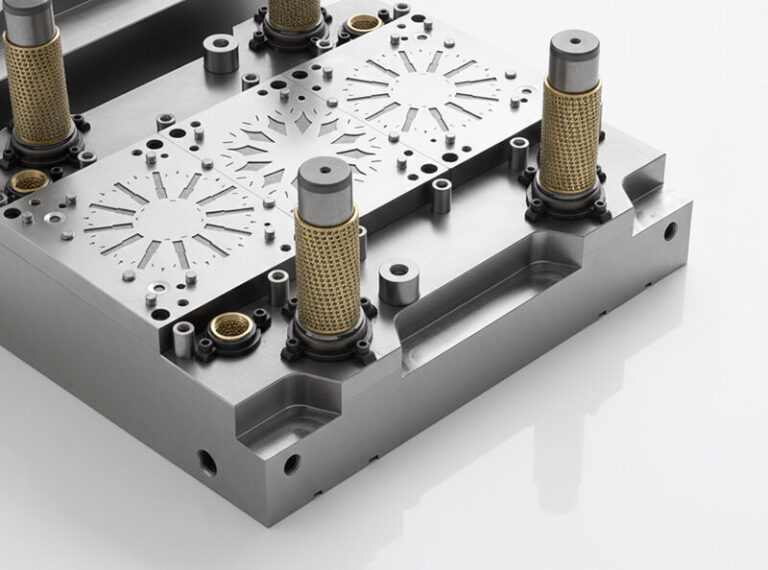

What is Metal Stamping?

Metal stamping is a manufacturing process that uses a die and press to shape metal into a specific form or design. The process involves applying high pressure to a metal sheet, causing it to conform to the shape of the die. This technique is widely used for producing large volumes of parts, particularly for the automotive, electronics, and appliance industries.

Key Features of Metal Stamping:

- High-Volume Production: Metal stamping is ideal for creating large batches of parts with uniformity and precision.

- Die-Based Process: The use of custom dies enables manufacturers to produce parts with consistent dimensions and complex shapes.

- Versatility: Metal stamping can be used for a variety of operations, including blanking, piercing, bending, and embossing.

- Material Range: Metal stamping works with various metals, such as steel, aluminum, brass, and stainless steel.

Applications of Metal Stamping

- Automotive Parts: Metal stamping is used to create car body panels, brackets, and engine components.

- Electronics: Stamped parts are used for connectors, housings, and brackets.

- Appliances: Commonly used in the production of metal parts for washing machines, refrigerators, and microwaves.

What is Engraving?

Engraving, on the other hand, is a process where designs or text are carved or etched into the surface of a material, typically metal. The engraving process can be achieved using various methods such as manual engraving, laser engraving, or rotary engraving. Unlike metal stamping, which involves shaping material, engraving is primarily focused on creating detailed markings or textures on the surface of the material.

Key Features of Engraving:

- Precision Marking: Engraving is used for adding intricate patterns, logos, or text on the surface of the material.

- Surface-Level Process: The design is carved into the surface, rather than altering the material’s shape.

- Multiple Methods: Engraving can be done manually, using mechanical tools, or automatically with laser engravers or CNC machines.

- Material Versatility: Engraving is commonly performed on metals, plastics, glass, and even wood.

Applications of Engraving

- Jewelry: Engraving is widely used for creating personalized engravings on rings, necklaces, and bracelets.

- Awards & Trophies: Commonly used to add names, logos, and designs to awards and commemorative plaques.

- Industrial Marking: Engraving is used for serial numbers, barcodes, and other identifying marks on machinery and equipment.

Key Differences Between Metal Stamping and Engraving

1. Purpose and Output

The primary difference between metal stamping and engraving lies in their intended purposes and the type of output they produce. Metal stamping is used to shape and form metal, creating functional parts with complex geometries. In contrast, engraving is used to mark or decorate the surface of the material with detailed designs, text, or patterns.

- Metal Stamping: Primarily used for producing parts and components with specific shapes.

- Engraving: Used for creating markings, logos, or decorative features on the surface of a material.

2. Process Involved

The processes for metal stamping and engraving are quite distinct. Metal stamping involves high-pressure machinery and custom dies to shape metal sheets into specific forms. This process is typically automated and suited for high-volume production. On the other hand, engraving involves removing material from the surface to create detailed designs. It can be done manually or with CNC machines and laser engravers, offering a high level of detail and precision.

- Metal Stamping Process: Involves pressing metal sheets into molds (dies) under high pressure.

- Engraving Process: Involves carving or etching into the surface using mechanical tools or lasers.

3. Material Considerations

While both techniques can be applied to a range of materials, metal stamping is typically used for thicker metal sheets that need to be shaped into specific forms. Engraving, on the other hand, is most commonly used for surface treatments on metals, plastics, and other materials, making it ideal for applications requiring detailed marks or decorative elements.

- Metal Stamping: Works with various metals and is suited for high-strength materials.

- Engraving: Suitable for a wide range of materials, including metals, plastics, and glass.

4. Level of Detail

Engraving excels when it comes to creating fine details. Whether it’s a serial number, logo, or intricate designs, engraving offers a level of detail that is not typically achievable through metal stamping. Stamping, while precise, focuses more on shaping and forming the material rather than creating intricate surface markings.

- Metal Stamping: Best for creating uniform shapes and parts at a large scale.

- Engraving: Best for creating detailed, fine markings or decorative features.

5. Cost and Production Volume

Metal stamping is generally more cost-effective for large production volumes due to its automation and the ability to produce identical parts rapidly. Engraving, depending on the method used, can be more labor-intensive and time-consuming, especially for high-detail designs, making it more suitable for smaller runs or custom jobs.

- Metal Stamping: Cost-effective for mass production, especially in high-volume runs.

- Engraving: More suited for small-scale or customized production with intricate details.

When to Choose Metal Stamping vs. Engraving

Choose Metal Stamping When:

- You need to produce large quantities of functional metal parts with specific shapes.

- The part requires high-strength materials and precise dimensions.

- The design involves forming or shaping the material, such as creating automotive parts or appliance components.

Choose Engraving When:

- You need to add detailed markings, logos, or text to the surface of a part.

- The part requires customization or personalization, such as jewelry, awards, or industrial marking.

- You need fine, precise detailing that is difficult to achieve with other methods, such as intricate designs or serial numbers.

Conclusion

Both metal stamping and engraving are vital techniques in precision manufacturing, but they serve different purposes. Metal stamping is the go-to method for creating functional, high-volume parts with specific shapes, while engraving is ideal for adding detailed markings or custom designs to the surface of a material.