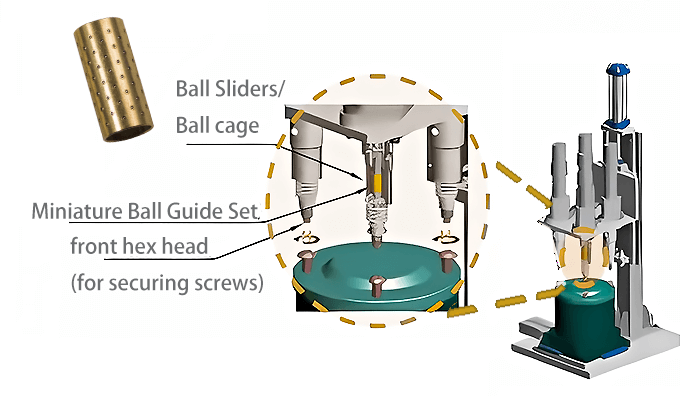

Miniature Ball Guide Set for Automation

The Miniature Ball Guide Set is widely used in various industries, such as semiconductor manufacturing, automated assembly lines, and CNC machines. It is adeptly utilized in stamping dies and FA automation equipment, offering crucial functionalities such as friction reduction and facilitating both linear and combined rotational movements. Manufacturers can provide balls of different sizes and densities tailored to specific requirements. Its design, characterized by cross-aligned balls, enables seamless transitions between linear, rotational, and compound motions.

One of the standout features of the Miniature Ball Guide Set is its capability to perform low-friction rolling motion, ensuring minimal resistance due to the non-circulating nature of its balls. Precision engineering ensures a tight tolerance with gaps typically controlled within -3 to +8 microns (reference values), ensuring precise and smooth operation during dynamic movements.

In addition to its functional prowess, the Miniature Ball Guide Set boasts a compact design. Guide bushings are available from an outer diameter of just 5mm(Contact the manufacturer for custom size options), making it an optimal choice for applications where space is at a premium. This compactness is particularly advantageous in scenarios requiring both rotational and linear movements, effectively reducing overall equipment size.

Applications such as automatic screw locking machines benefit significantly from the set’s ability to minimize friction, thereby ensuring precise control over the screw insertion process.

Comprising essential components like the guide shaft, miniature ball cage, and guide bushings, the Miniature Ball Guide Set offers customization options in cage material to suit specific environmental demands.

Materials such as aluminum, copper, or plastic can be chosen based on factors like durability, environmental compatibility, and weight considerations. Furthermore, the number and arrangement of balls can be tailored to accommodate varying friction coefficients and specific operational requirements, further enhancing versatility and performance.

Choosing a manufacturer with proven expertise in producing high-quality miniature ball cages is paramount. GUNRI stands out in this regard, catering to industries including automotive, aerospace, medical, electronics, and more. With a reputation for precision and reliability, GUNRI serves as a trusted partner for integrating advanced automation solutions.

For more detailed insights into the Miniature Ball Guide Set and how it can enhance your automation processes, please contact GUNRI.