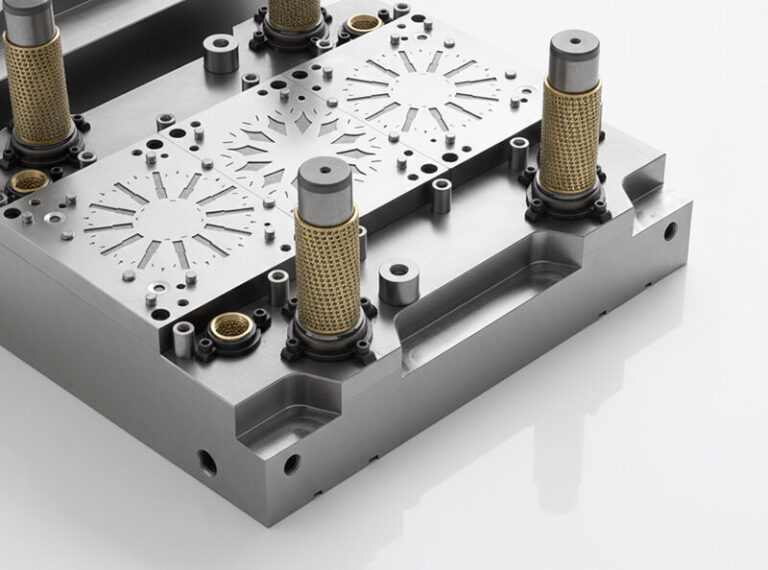

Completion of -190°C Cryo-Treated Guide Pins & Bushings

We are pleased to announce the successful completion of our latest batch of precision guide pins and bushings, having undergone a rigorous ultra-deep cryogenic treatment at an extreme -190°C. This advanced thermal processing represents a significant step forward in component…