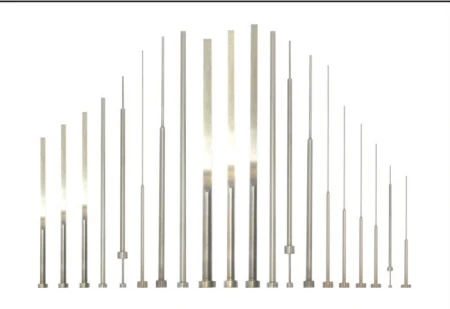

exagonal Pillar Guide Sleeve: High Stability Precision Component

Introduction: In fields such as motor manufacturing and high-speed mold stamping, stability and precision are crucial factors. The hexagonal pillar guide sleeve, as a component with stable structure and precision production, plays an important role in these fields. This article…