A Beginner’s Guide to Nitrogen Gas Springs in Molds

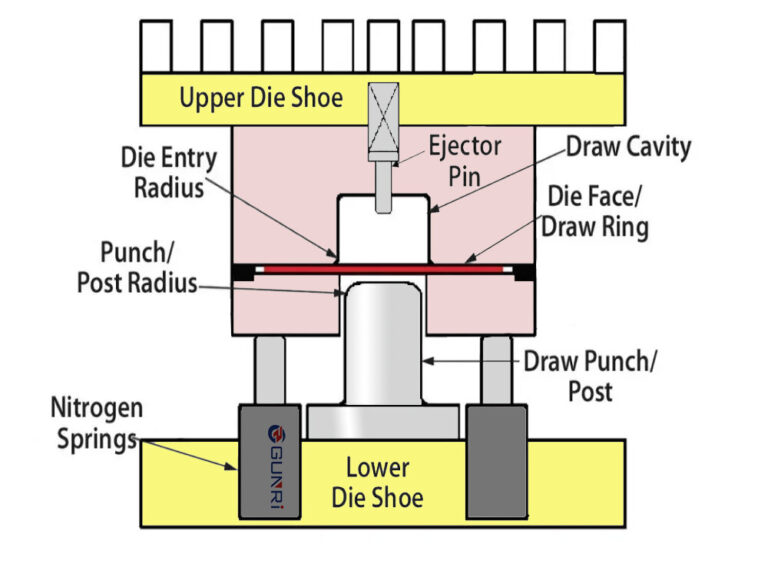

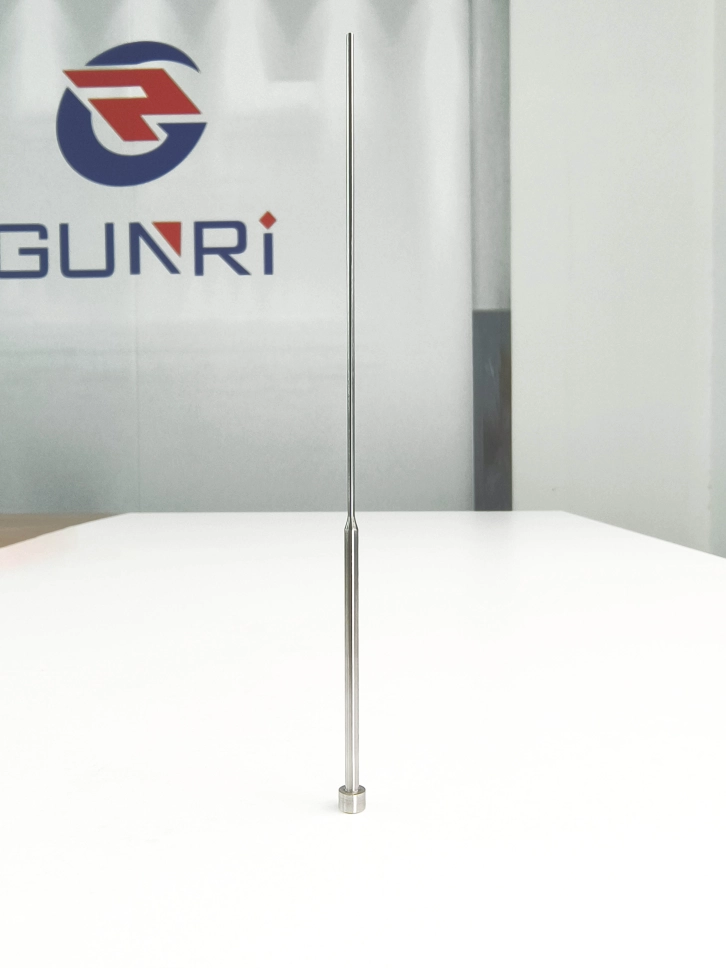

Nitrogen gas springs are increasingly becoming essential components in modern mold and die design. They offer significant advantages over traditional mechanical springs, contributing to improved mold performance, longer lifespan, and enhanced part quality. This guide provides a foundational understanding of…