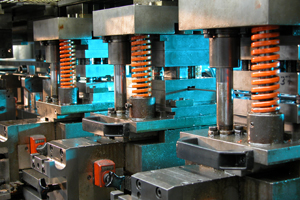

Nhà Cung Cấp Khóa Phân Khuôn Chịu Nhiệt PL-J Uy Tín

Trong ngành công nghiệp chế tạo khuôn mẫu, khóa phân khuôn chịu nhiệt PL-J là một trong những sản phẩm chuyên dụng quan trọng, giúp cố định và chịu được nhiệt độ cao trong quá trình sản xuất. Chúng tôi…