Die Set Guide Posts Manufacturers: A Comprehensive Guide

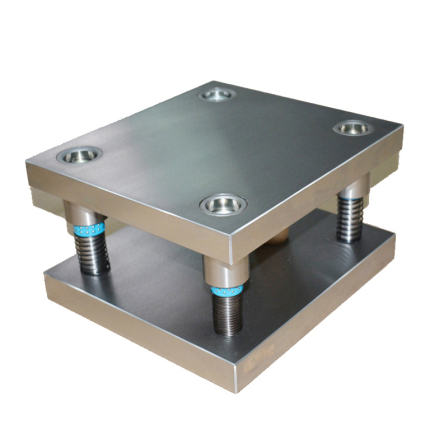

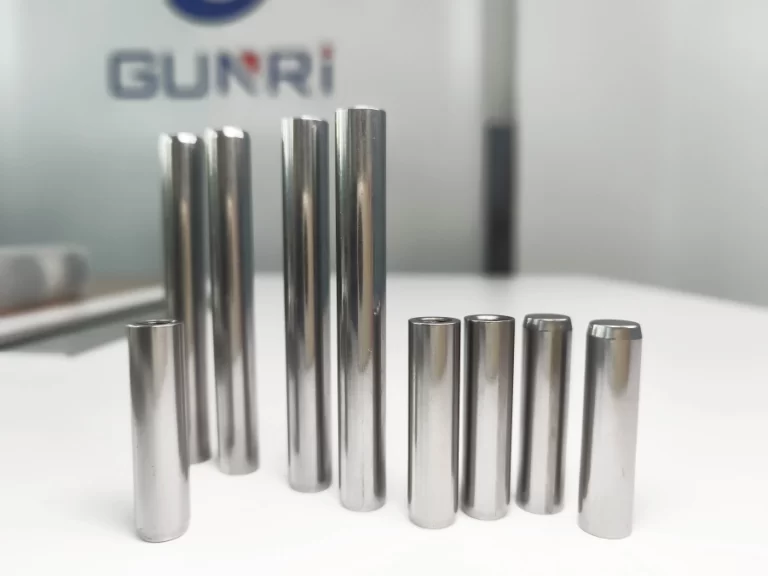

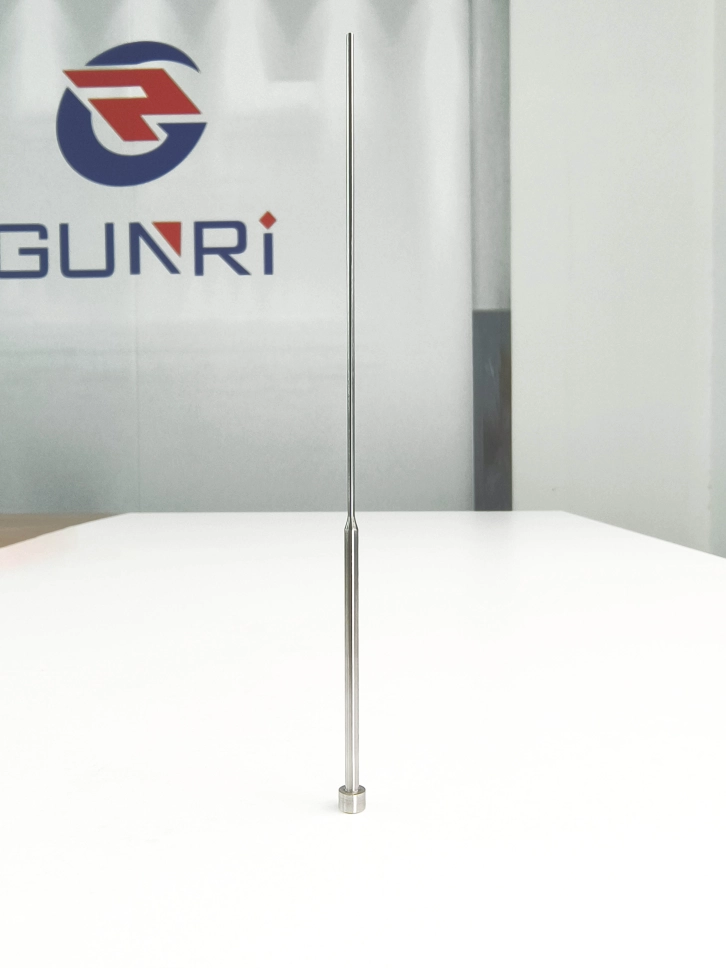

In the precision-driven world of die set manufacturing, guide posts play an essential role in ensuring accurate alignment and smooth operation of dies. As manufacturers of die set guide posts, we understand the significance of delivering products that enhance productivity,…