Nitrogen Gas Springs Suppliers

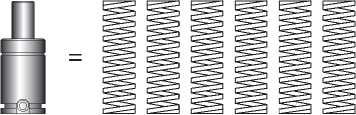

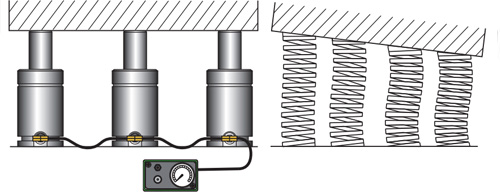

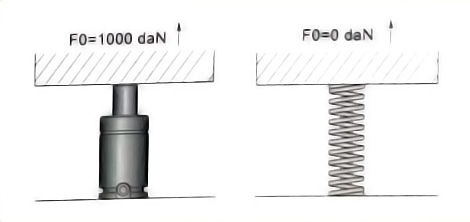

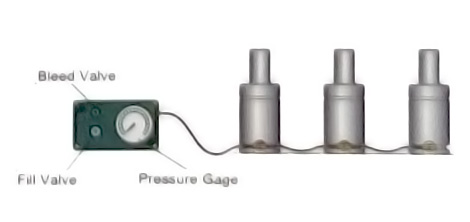

Our state-of-the-art solutions are engineered to transform your manufacturing processes, ensuring enhanced control, stability, and productivity.

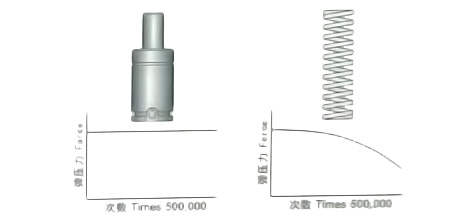

Gunri Gas Springs: Your Assurance of Reliability, Safety, and Durability

Meeting Stringent European Pressure Equipment Standards

Rest assured, Gunri gas springs are meticulously designed, crafted, and subjected to rigorous testing to meet the exacting requirements of the European Pressure Equipment Directive, ensuring their quality and performance.