Performance Advantages of Plastic Ball Cages in High-Speed Die Sets

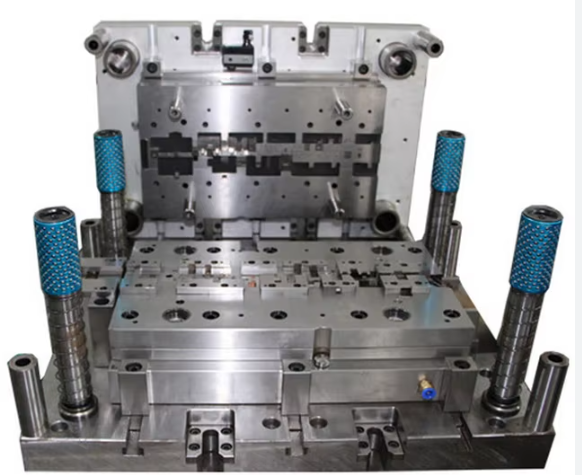

Introduction — Rising Demands in High-Speed Stamping

In the current wave of manufacturing upgrades, high-speed stamping has been growing rapidly at an annual rate of 12–15%. Particularly in the automotive and electronics sectors, production speeds exceeding 1000 strokes per minute (SPM) have evolved from a “special requirement” to a mainstream standard.

According to the China Die & Mould Industry Development Report (2024), 38% of domestic manufacturers now operate stamping equipment running at 1000–1500 SPM, a 21% increase compared with 2020.

At such extreme frequencies, die components are exposed to 60,000–90,000 dynamic impacts per hour. When the radial runout of guide posts and bushings exceeds 0.005 mm, the defect rate of stamped parts may rise by over 30%. Therefore, the precision and durability of the guiding system—especially the interaction between the guide post, bushing, and ball cage—directly determine die life.

Traditional metal-caged dies typically last 0.8–1.2 million strokes, while optimized plastic ball cages can exceed 2 million strokes. Under these demanding conditions, plastic cages have demonstrated 40–60% lower wear rates, becoming a key component in achieving stable high-speed performance.

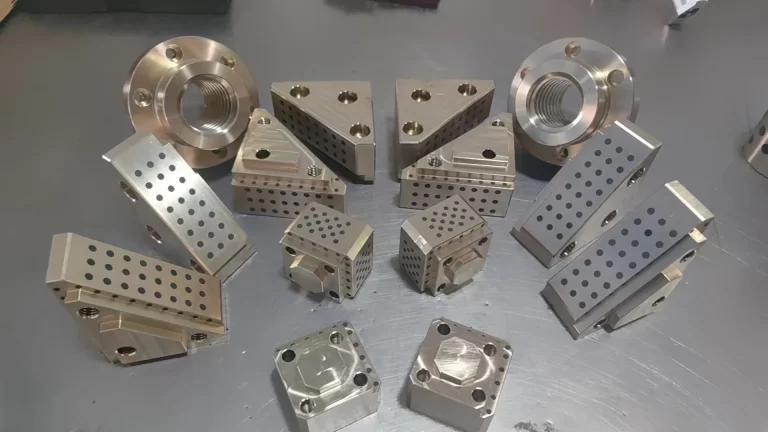

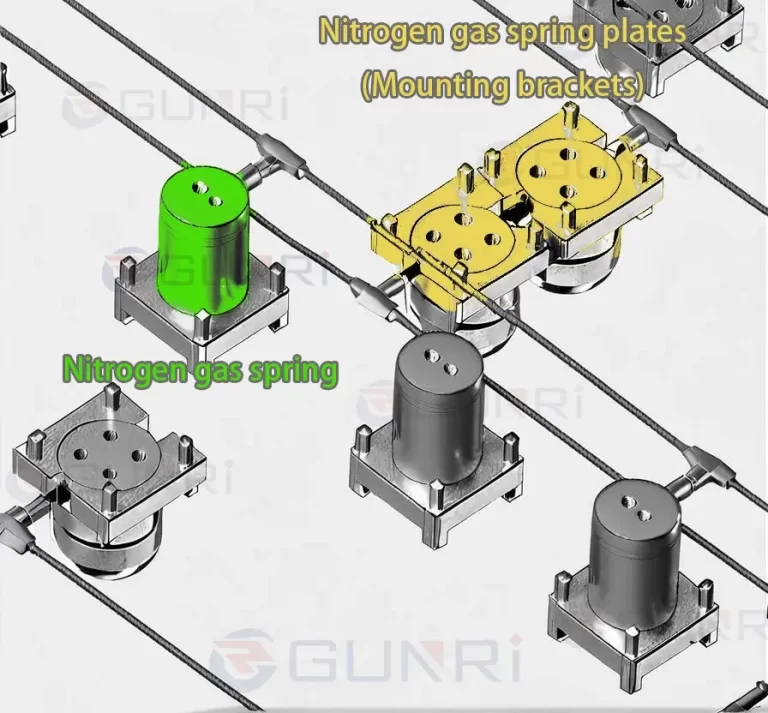

Material and Structural Characteristics of Plastic Ball Cages

Plastic ball cages are manufactured from high-performance engineering polymers tailored for specific operating conditions:

- POM (Polyoxymethylene):

With a friction coefficient as low as 0.15–0.25 (compared to 0.35–0.45 for brass) and a density of 1.41 g/cm³—just one-sixth that of brass—POM maintains over 90% dimensional stability at 100–120°C, ideal for moderate-speed stamping (1000–1200 SPM). - PA (Polyamide, Nylon):

When reinforced with glass fiber, tensile strength reaches 80–120 MPa, comparable to low-carbon steel. Its impact resistance keeps deformation below 0.5% even at 1200–1400 SPM, making it suitable for precision connector molds. - PEEK (Polyetheretherketone):

Offering continuous operating temperatures up to 250°C, PEEK maintains stable friction performance at 1500–1800 SPM, with excellent chemical resistance—ideal for fine electronic connector stamping.

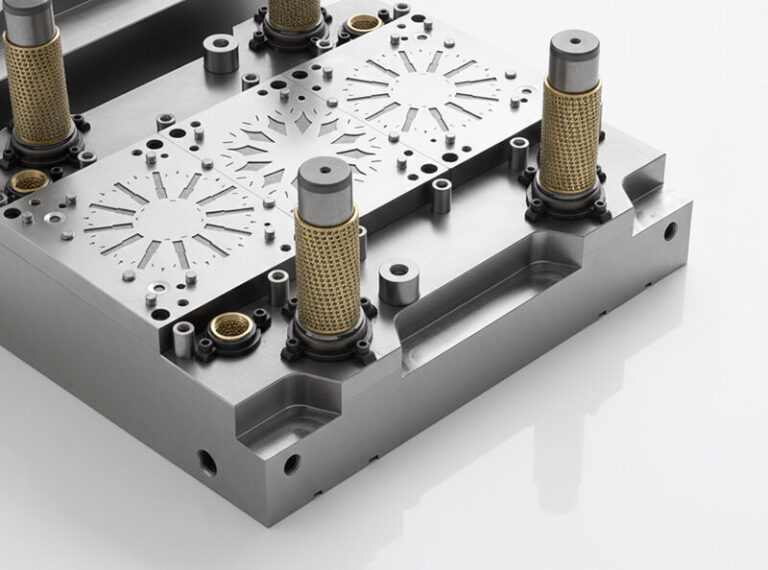

Structurally, most cages use a petal-type or pocket-type ball arrangement. The clearance between ball and pocket is precisely controlled to 0.02–0.05 mm, ensuring smooth rolling without chatter at high speeds.

Thanks to their self-lubricating properties, plastic cages can reduce external lubrication demand by over 70%. In ultra-clean applications such as semiconductor lead-frame stamping, contamination levels can be kept below 10 particles per cubic meter, meeting strict cleanliness standards.

Inertia and Motion Behavior at High Stroking Speeds

When stroking speeds exceed 1000 SPM, the inertial force of moving components increases proportionally to the square of velocity.

For example, a 20 mm-diameter brass cage weighs about 50 g, generating an inertial force of roughly 120 N during reversal at 1200 SPM. By contrast, a POM cage of the same size weighs only 8 g, producing just 19.2 N—one-sixth as much.

This difference in inertia has a direct effect on ball drag.

In metal cages, when the stroke speed rises from 800 to 1200 SPM, ball drag can increase 2.3 times, raising guide contact temperatures from 50°C to 85°C, and surface wear by 1.8 times.

Plastic cages, under the same conditions, exhibit only 35% of the drag and maintain a contact temperature below 60°C, reducing wear by 65%.

High-speed camera analysis (10,000 fps) shows that plastic cages react to directional reversal within 0.002 seconds, compared with 0.008 seconds for metal types. This rapid response ensures synchronized ball movement, maintaining radial runout below 0.003 mm even at 1500 SPM—far superior to the 0.008 mm of metal cages.

Functional Benefits in High-Speed Die Sets

1. Reduced Wear and Extended Service Life

In a 1200 SPM motor lamination test, guide posts with POM cages retained surface roughness (Ra) below 0.2 μm after 1 million strokes, whereas brass cages increased to 0.8 μm.

Bushing replacement intervals extended from 3 months to 8 months, reducing maintenance frequency by 62.5%.

2. Enhanced Stability and Lower Defect Rates

A connector manufacturer using glass-fiber-reinforced PA cages at 1300 SPM saw the dimensional defect rate drop from 5.2% to 1.1%.

Daily production increased by 18%, saving approximately ¥780,000 (≈USD 110,000) per year in scrap loss.

3. Reduced Maintenance and Higher Equipment Utilization

Self-lubricating cages extend lubrication intervals from weekly to monthly, and each maintenance session shortens from 2 hours to 0.5 hours.

This results in ≈96 hours less downtime per year, adding production value of ≈¥480,000 (≈USD 68,000) annually per machine line.

4. Improved Thermal Control and Dimensional Precision

In continuous 24-hour stamping at 1400 SPM, temperature variation between the top and middle of the guide post was only 3°C with plastic cages, compared with 8°C in metal ones.

This ensured dimensional consistency within ±0.005 mm, meeting the precision standards for automotive sensor components.

Application Cases and Practical Results

- Motor Lamination Stamping:

A major motor manufacturer running 1200 SPM stator lamination presses adopted PEEK cages, increasing die life from 1.0 to 2.2 million strokes and cutting mold cost per ton of laminations from ¥80 to ¥36, saving over ¥3 million annually.

The lamination stacking factor improved from 0.95 to 0.97, enhancing motor efficiency by 2.3%. - Precision Electronic Connectors:

A semiconductor producer using PA66 glass-fiber cages at 1500 SPM reduced pin perpendicularity error from 0.10 mm to 0.05 mm, improving yield from 92% to 99.5%.

By minimizing lubrication, product cleanliness test pass rates rose from 85% to 100%, enabling entry into high-end consumer electronics markets. - Automotive Airbag Components:

In 1300 SPM stamping of gas generator housings, the low inertia of plastic cages limited wall-thickness deviation to 0.03 mm (industry standard: 0.08 mm).

Airbag deployment response time improved by 0.005 seconds, enhancing overall safety performance.

Conclusion — Toward Reliable High-Speed Precision

With their combined material and structural advantages, plastic ball cages act as performance accelerators in high-speed die systems.

Data shows that adopting plastic cages can:

- Extend die service life by 80–120%

- Reduce maintenance costs by 50–65%

- Lower defect rates by over 70%

As stamping speeds continue to surpass 1800 SPM, the technology will evolve toward composite materials (e.g., PEEK + carbon fiber) and integrated structural designs with built-in sealing features, pushing high-speed stamping toward higher precision, lower cost, and greater sustainability.

For toolmakers and end users, adopting plastic ball cages is not merely a “component replacement,” but a strategic step in upgrading high-speed stamping processes.

For a manufacturer producing one billion stamped parts annually, switching to plastic cages can save over ¥12 million (≈USD 1.7 million) per year in maintenance and scrap reduction—achieving a return on investment (ROI) of 1:3.5 and establishing a true competitive advantage in precision manufacturing.