Precision Tapered Guide Pillars: Enhancing Industrial Efficiency

Introduction: In the realm of precision engineering, the importance of meticulous alignment and smooth movement cannot be overstated. This is where tapered guide pillars, with their unique design and exceptional durability, come into play. In this article, we delve into the world of tapered guide pillars, exploring their construction, materials, and the vital role they play in enhancing industrial efficiency.

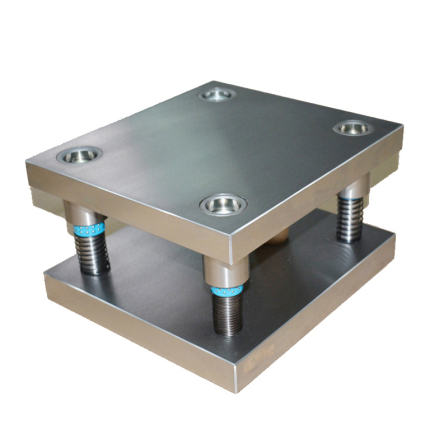

Construction and Materials: Tapered guide pillars are engineered with precision in mind. They are typically made from high-quality steel, renowned for its strength and durability. The steel used boasts a core strength of 900 N/mm², ensuring robustness even under heavy loads and in demanding working environments.

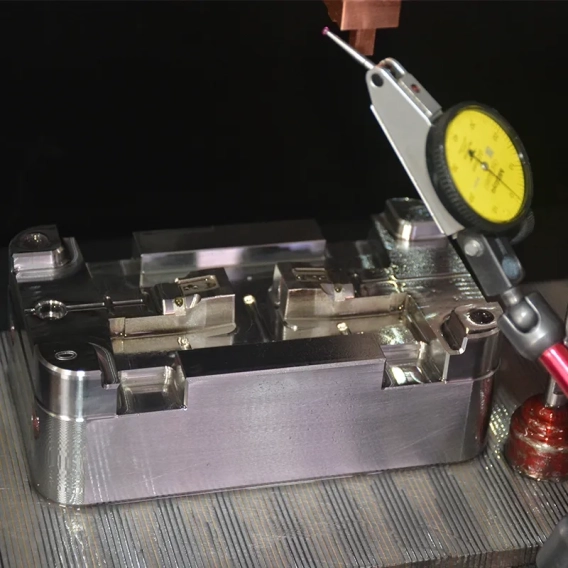

Surface hardening is a critical process employed to enhance the durability and wear resistance of the guide pillars. The surface hardness of these pillars reaches an impressive 60+3 HRC (Rockwell Hardness Scale), providing exceptional resistance to abrasion and ensuring longevity in operation. Additionally, the hardness penetration exceeds 1.8mm, further reinforcing the pillars’ ability to withstand the rigors of industrial usage.

Benefits and Applications: The precision and reliability offered by tapered guide pillars make them indispensable in various industrial applications. These pillars excel in providing accurate alignment and smooth movement, crucial for tasks such as die setting, mold alignment, and precision machining.

In the automotive industry, tapered guide pillars play a vital role in ensuring precise alignment during the assembly of components, thus contributing to the production of high-quality vehicles. Similarly, in the aerospace sector, where precision is paramount, these guide pillars aid in the fabrication of intricate components with tight tolerances.

Conclusion: In conclusion, tapered guide pillars stand as a testament to precision engineering at its finest. With their robust construction, high-quality materials, and impeccable performance, they elevate industrial efficiency and contribute to the production of superior-quality goods across various sectors. As industries continue to evolve, tapered guide pillars remain a steadfast ally, enabling precision and reliability in every operation they undertake.