Principles of Arrangement for Plastic Mold Components – Ejector Pins

The arrangement principles for ejector pins in plastic mold components are essential for ensuring efficient and effective mold operation. Here are the key principles:

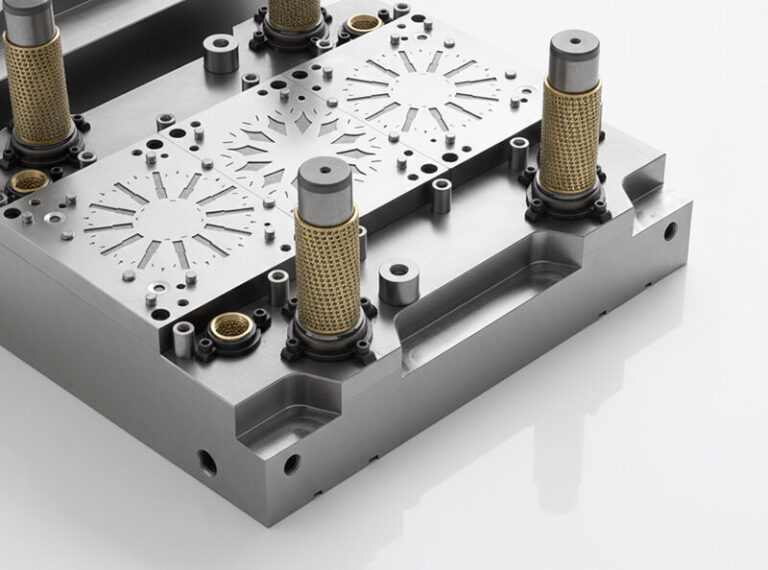

- Ejector pins should be arranged to balance the ejection force as much as possible. For complex structures requiring greater demolding force, the number of ejector pins should be increased accordingly.

- Ejector pins should be set in effective positions, such as bone positions, pillar positions, steps, metal inserts, and areas with localized thick plastic. Ejector pins on both sides of bone and pillar positions should be arranged as symmetrically as possible. Additionally, the centerline of ejector pins on both sides of pillar positions should ideally pass through the center of the pillar.

- When the depth of bone positions is ≥20mm or when it is difficult to arrange cylindrical ejector pins, flat ejector pins should be used. When flat ejector pins are required, they should preferably be used in the form of inserts to facilitate processing.

- Avoid using pointed or thin steel ejector pins, especially when the ejector pin’s top surface may come into contact with the front mold surface.

- Consider the spacing between ejector pins and runner channels to avoid affecting the processing and leakage of runner channels.

- Consider the exhaust function of ejector pins. Ejector pins should be arranged in areas prone to forming vacuum suction during ejection, such as large flat surfaces in the cavity. Although the clamping force on the plastic part may be small, vacuum suction can increase demolding force.

- For plastic parts with appearance requirements, ejector pins should not be arranged on the appearance surface. Alternative ejection methods should be used.

- For transparent plastic parts, ejector pins should not be arranged in areas requiring transparency.

In summary, proper arrangement of ejector pins in plastic mold components is crucial for ensuring smooth and efficient mold operation and achieving high-quality molded parts. Adhering to these principles helps minimize defects and optimize the production process.