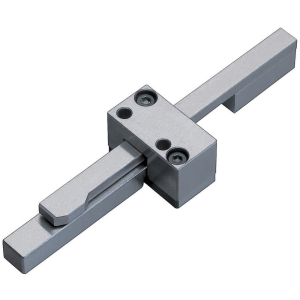

Latch Lock DKL

Internal Latch Lock DKLFeatures: Unique built-in device, different functions according to different installation methods, with internal locking buckle and secondary ejection function, can avoid conflicts between water transport and external installation parts.